Home page||Machinery service system||

Air compressors automatic operation & Control system air

Automatic operation

Before the general introduction of control equipment, air compressors were stopped and started by engine room staff, as necessary, to maintain air receiver pressure. In port or at sea, this usually meant operating one compressor for about half an hour daily unless air was being used for the whistle (during fog), for work on deck or for other purposes. Whilst manoeuvring, the compressors would be started and stopped very frequently unless they were steam driven, when demand could be met by varying the speed.

Some compressors were fitted with unloaders to hold the suction valve plates off their seats when receiver pressure reached the maximum and this gave a degree of automatic operation. To drain the coolers continuously during running, an automatic device was fitted to each cooler. Compressors are now normally arranged for automatic stop and start as dictated by demand through pressure variation.

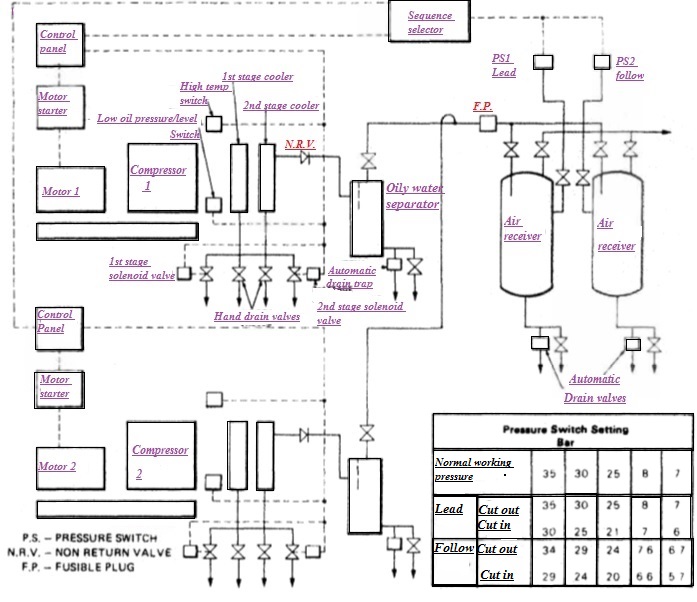

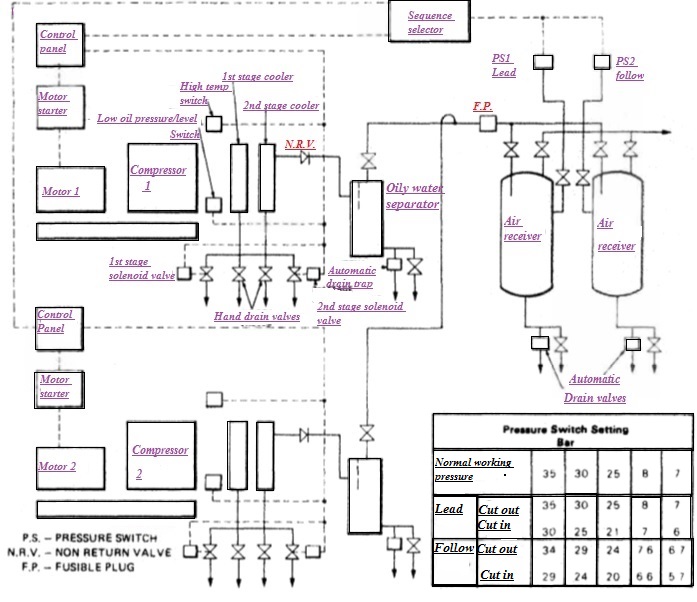

Figure 1: Automatic operation of air compressors (Hamworthy Ltd)

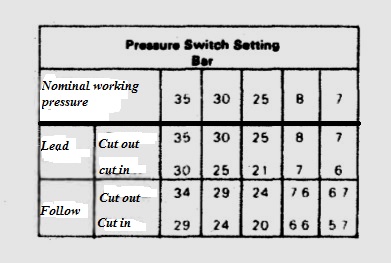

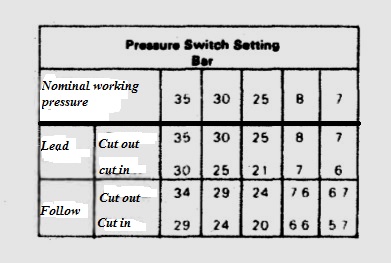

Figure 1 above shows a scheme for the automatic starting and stopping of two machines. Either machine can be selected as lead' machine. This will run preferentially during manoeuvring and at other times, automatically stopping and starting under the control of a pressure switch on the air receiver. The 'follow' machine is arranged to back-up the lead' machine during manoeuvring, cutting in after the lead' machine when the receiver pressure falls below a pre-set value (see the table in Figure 2).

Figure 2: pressure switch setting bar

When the pressure switch stops the compressor, the drain valves open automatically. First and second stage cooler drains (Figure 1) may be operated by solenoids or other means. The drain valves are also opened briefly on an intermittently timed cycle thus providing automatic draining as well as unloading. The cooler drain valves are normally open whilst the compressors are not in use to provide unloaded starting. Two timers are located in the control panel.

One delays the closure of the cooler drains to give the compressor time to run up to speed and to control the time for which drain valves remain open during periodic draining. The other timer controls the frequency of the periodic draining, in certain applications involving the filtration of compressed air particularly those associated with control equipment and the safety of human operators - it is imperative that an efficiency of virtually 100% be achieved in the removal of oil, both in the droplet stage and in its vapour form, together with moisture and other pipeline impurities, A non-return valve in the discharge line of each compressor is necessary. It should be of the low inertia type.

Automatic shut-off of the cooling water supply, where independent of the compressor, should also be arranged. This could be achieved with a valve, normally closed, which is opened by the first stage pressure acting on a diaphragm.

Control system air

Pneumatic control equipment is sensitive to contaminants which may be in the air. Viscous oil and water emulsions can cause moving parts to stick and produce general deterioration of diaphragms and other parts made of rubber. Water can cause rust build up which may also result in parts sticking or being damaged by rust particles. Metallic wear and other small particles can cause damage by abrasion. Any solids mixed with oil and water emulsions can conspire to block small orifices. Clean and dry control air is thus essential for the trouble free operation of systems.

Air leaving a conventional compressor usually contains oil carried over from the cylinder and water precipitated in the coolers. The two liquids combine to form an emulsion as witnessed when testing the drains. Dust and other small particles are carried through the compressor with the air, because the suction filters are necessarily fairly coarse. Usually compressor coolers are drained automatically.

The receivers may be drained automatically or by engine room staff, sometimes as often as twice per day. The emulsion removed from compressor coolers and air receivers, has a viscosity which varies with machinery space conditions. Some emulsions are very viscous and they cause most problems with sticking. When the source of control and instrument air is main air compressors and reservoirs, then special provision is necessary to ensure that air quality is high.

The reducing valve which brings the main air pressure to the 7 or 8 bar required by the control air system, can be affected by emulsion carry over and can require frequent cleaning to stop it from sticking. Automatic drain traps may be fitted to the control air system, but many have traps which require daily draining by staff. A moderate amount of free moisture in the control air could be removed by ceramic filters but to give the desired dryness factor an absorbent type drier may be considered necessary or a drier using refrigeration.

Control air from starting air at 15 to 40 bar

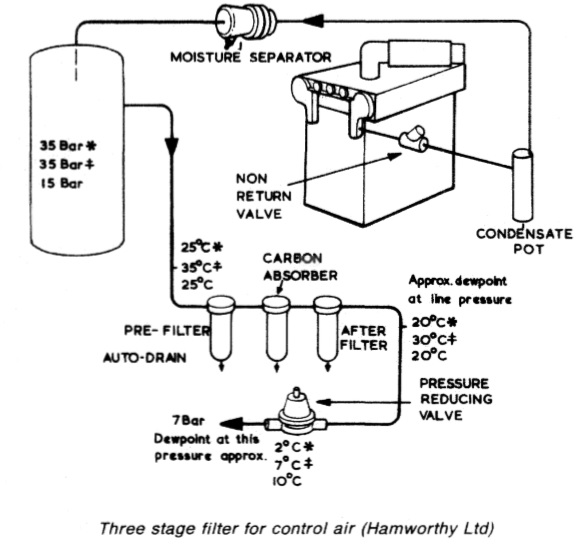

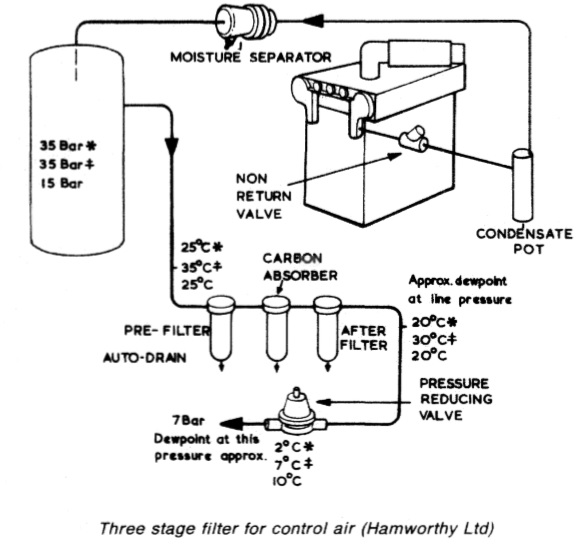

A three stage filtration system (Figure 3) employing a pre-filter, a carbon absorber, and an after filter, may be installed to deliver good quality air. The pre-filter contains a medium grade porous ceramic element and removes the gross atmospheric impurities from the air.

Figure 3: A three stage filtration system for control air

The absorber is packed with activated carbon and provides a deep bed producing an evenly distributed iow for the removal of vapours (it can also remove Bavours or taints). The after filter contains a fine grade porous ceramic element preventing the ingress of any migrating carbon particles to the pipeline, thereby assuring a pure supply. Air from the main engine starting air receiver enters the filter assembly fully saturated, that is, carrying some free water and oil vapour. Virtually all of the free water and oil should be removed. Due to precipitation through the filter, more moisture will be removed from the air reducing the dew point by approximately 5 deg C.

When the pressure reducing valve drops the pressure to 7 bar, the dew point falls sufficiently for the air to be suitable for immediate use in a control air system without the use of absorption driers. The reducing valve for this arrangement is also protected from the effects of emulsion in the air.

Oil-free and non-oil-free rotary compressors

Both these machines deliver wet air which must be dried as described above but the non-oil-free machine passes over some oil which must also be removed, This is usually effected by a pre-filter followed by a carbon absorber, which removes the oil, followed by an after filter (to remove the remaining free moisture). Either system can be found at sea.

Summarized below some of the basic procedure of machinery service systems and equipment :

- Marine air compressor

A single stage compressor used to provide air at the high pressures required for diesel engine starting, would unfortunately generate compression temperatures of a level similar to those in a diesel. Such heat would be sufficient to ignite vaporized oil in the same way as in a compression-ignition engine. The heat produced in a single stage of compression would also be wasteful of energy.....

- Air starting system

Air at a pressure of 20 to 30 bar is required for starting main and auxiliary diesel engines in motorships and for the auxiliary diesels of steamships. Control air at a lower pressure is required for ships of both categories and whether derived from high pressure compressors through reducing valves or from special control air compressors, it must be clean, dry and oil free.....

- automatic-operation-air-compressor

Before the general introduction of control equipment, air compressors were stopped and started by engine room staff, as necessary, to maintain air receiver pressure. In port or at sea, this usually meant operating one compressor for about half an hour daily unless air was being used for the whistle (during fog), for work on deck or for other purposes. ....

- Compressed air systems for steamships

A compressed air system is necessary to supply air for boiler soot-blower air motors, hose connections throughout the ship and possibly diesel generator starting. A general service air compressor would supply air at 8 bar but greater pressure (as for diesel ships) would be necessary for diesel starting.....

- Two stage starting air compressor

Hamworthy 2TM6 type which was designed for free air deliveries ranging from 183 m3 per hour at a discharge pressure of 14 bar to 367m3 per hour at 42 bar. The crankcase is a rigid casting which supports a spheroidal graphite cast iron crankshaft in three bearings.....

- Fuel handling

Fuels and lubricating oils are obtained from crude primarily by heating the crude oil, so that vapours are boiled off and then condensed at different temperatures. The constituents or fractions are collected separately in a

distillation process.....

- Fuel transfer and fire risk

The oil fuel system provides the means for delivering fuel from the receiving stations at upper deck level, port and starboard, to double-bottom or deep bunker tanks. Sampling cocks are fitted at the deck connections to obtain a representative specimen for (a) shore analysis; (b) on board testing; and (c) retention on the ship.....

- High density fuel treatment

The density of a fuel tested at 15 deg C may approach, be equal to or greater than that of water. With high density fuels, the reduction in density differential between fuel and water can cause a problem with separation but not with the usual solid impurities.....

- Viscosity controller

A continuous sample of the fuel is pumped at a constant rate through a fine capillary tube. As the flow through the tube is laminar, pressure drop across the tube is proportional to viscosity. In this unit an electric motor drives the gear pump through a reduction gear, at a speed of 40 rpm......

- Fuel blenders

Conventionally, the lower cost residual fuels are used for large slow speed diesel main engines and generators are operated on the lighter more expensive distillate fuel. The addition of a small amount of diesel oil to heavy fuel considerably reduces its viscosity and if heating is used to further bring the viscosity down then the blend can be used in generators with resultant savings.....

- Fuel heaters

The system which delivers residual fuel from the daily service tank to the diesel or boiler, must bring it to the correct viscosity by heating.For burning heavy fuel oil in a boiler furnace, or a compression-ignition engine, it is necessary to pre-heat it....

- Homogenizer

The homogenizer provides an alternative solution to the problem of water in high density fuels. It can be used to emulsify a small percentage for injection into the engine with the fuel. This is in contradiction to the normal aim of removing all water, which in the free state, can cause gassing of fuel pumps, corrosion and other problems......

- Package boiler combustion system

The elementary automatic combustion system based on a two flame burner is used for many auxiliary boilers. The burner is drawn oversize to show detail. Various different control systems are employed for the arrangement.....

- Lubricating oil treatment

Mineral oils for lubrication are, like fuel, derived from crude during refinery processes. Basic stocks are blended to make lubricants with the desired properties and correct viscosity for particular duties. ....

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||