Home page||Cooling ||

Closed feed system and feed heating for motor ships

To ensure trouble-free operation of water-tube boilers the feed water must be of high quality with a minimal solid content and an absence of dissolved gases. Solids are deposited on the inside surfaces of steam generating tubes, as the water boils off, and the scale so formed causes overheating and failure. Dissolved gases tend to promote corrosion. Distilled water used as boiler feed has a great affinity for gases in the atmosphere.

Chemical treatment is aimed at preventing corrosion problems but the boiler closed feed system must play its part in maintaining minimal contact between feed water and air at every stage and in promoting the dissociation and removal of any air or other gases. The feed system also assists efficient operation by condensing used steam and returning it to the boiler as feed at the highest temperature attainable economically. In practical terms, this means maximum recovery of the latent heat in steam.

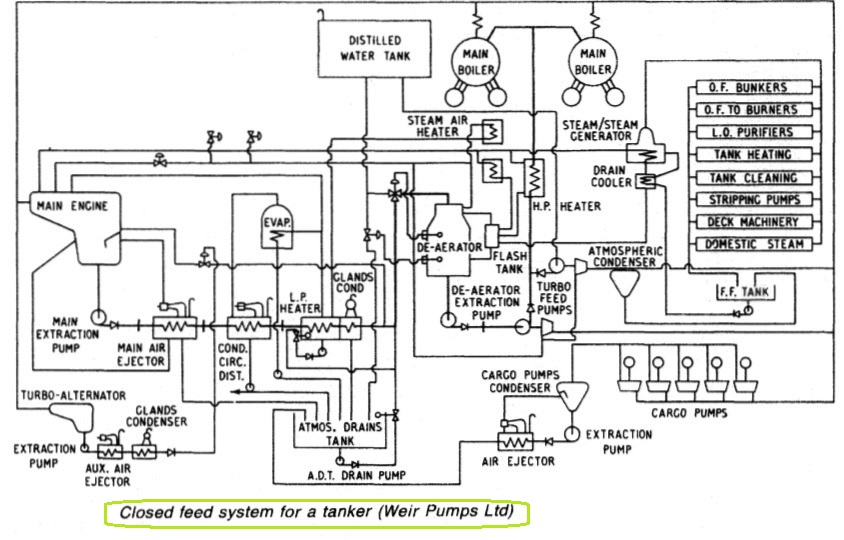

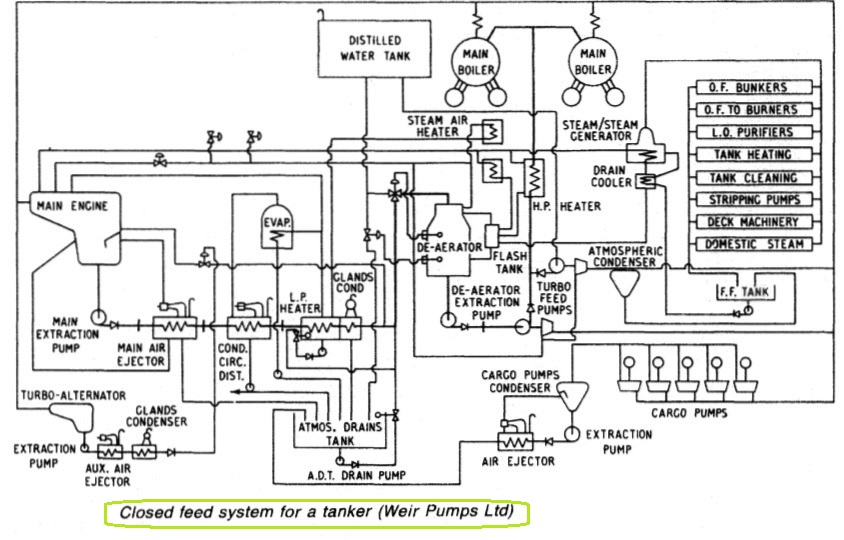

Figure 1:closed feed system for a tanker

Regenerative condensers and de-aerators are two major components in the complex feed systems which have been evolved. The feed system for a tanker (Figure 1) shows a superheated steam supply from two water-tube boilers to the main propulsion turbine, the turbo-alternator and for cargo pumps. Each of these is served by a separate condenser and extraction pumps which return condensate to the closed feed system.

The feed system and feed heating

Non-condensable gases and some vapour are removed from the main condenser (Figure 1) by an air ejector, cooled by the main condensate and released in the ejector condenser. The condensed ejector steam passes with other clean drains (gland stearn condenser, low pressure feed heater, evaporator) to a drains tank from which a pump draws, to discharge, with the mains condensate, to the de-aerator. It is common practice to reflux these drains, that is to return them to the main condenser in the form of a spray at a high level where, meeting the turbine exhaust, they are de-aerated before mixing with the main body of the condensate and being removed by the condensate extraction pump.

Heating steam for the steam/steam generator, the de-aerator and the low pressure feed heater are bled from the main turbines at appropriate stages, so that all of the latent heat Is recovered. The feed pump exhaust is treated similarly. The steam/steam generator, providing low pressure steam for services whose condensate may be contaminated, has its own separate feed system. The centrifugal extraction pump, driven either by electric motor or steam turbine, draws from the condenser and delivers to a de-aerating heater through the heat exchangers already mentioned.

Another extraction pump passes the de-aerated feed to a multi-stage centrifugal pump, also either electric motor or, more often, turbine driven. The pump delivers the feed to the boilers at a temperature approaching that of saturation through a high pressure feed heater, supplied with steam bled from the high pressure turbine. Make-up feed is produced by evaporation and distillation (sometimes double) at subatmospheric pressure, stored in a tank and introduced to the boilers from the main condenser with the refluxed drains or through the de-aerator. The feed pumps, feed piping and fittings are duplicated.

Summarized below various circulating systems for motorships, some of the basic procedure of heat exchangers & control of temperatures:

- Sea water circulation-systems

The usual arrangement for motorships has been to have sea-water circulation of coolers for lubricating oil, piston cooling, jacket water, charge air, turbo-charger oil (if there are sleeve type bearings) and fuel valve cooling, plus direct sea-water cooling for air compressors and evaporators....

-

Shell and tube heat exchangers for engine cooling water and lubricating oil cooling

Shell and tube heat exchangers for engine cooling water and lubricating oil cooling have traditionally been circulated with sea water. The sea water is in contact with the inside of the tubes, tube plates and water boxes....

-

Plate type heat exchanger

The obvious feature of plate type heat exchangers, is that they are easily opened for cleaning. The major advantage over tube type coolers, is that their higher efficiency is reflected in a smaller size for the same cooling capacity....

-

Details of charged air cooler

The charge air coolers fitted to reduce the temperature of air after the turbo-charger and before entry to the diesel engine cylinder, are provided with fins on the heat transfer surfaces to compensate for the relatively poor heat transfer properties of air....

-

Maintenance of heat exchangers

The only attention that marine heat exchangers should require is to ensure that the heat transfer surfaces should remain substantially clean and flow passage generally clear of obstructions. Indcation that fouling has occured is given by a progressive increase in the temperature difference between the two fluids, and change of pressure....

-

Central cooling system & Scoop arrangement for motorships

The corrosion and other problems associated with salt water circulation systems can be minimized by using it for cooling central coolers through which fresh water from a closed general cooling circuit is passed. The salt water passes through only one set of pumps, valves and filters and a short length of piping.....

-

Circulating systems for steamships

The main sea-water circulating system for a ship with main propulsion by steam turbine is similar to that of a motorship with a central cooling system. The difference is that the sea water passes through a ....

- Closed feed system and feed heating for motor ships

To ensure trouble-free operation of water-tube boilers the feed water must be of high quality with a minimal solid content and an absence of dissolved gases. Solids are deposited on the inside surfaces of steam generating tubes,....

- Marine condenser assembly

A condenser is a vessel in which a vapour is deprived of its latent heat of vaporization and so is changed to its liquid state, usually by cooling at constant pressure. In surface condensers, steam enters at an upper level, passes over tubes in which cold sea water circulates, falls as water to the bottom and is removed by a pump (or flows to a feed tank)....

-

Three stage air ejector with internal diffusers

A steam-jet ejector may be used to withdraw air and dissolved gases from the condenser. In each stage of the steam-jet ejector, high pressure steam is expanded in a convergent/divergent nozzle. ...

- Pressure governor for motor ships

The main feature of the governor is that if the pump loses suction the steam ports are opened wide, allowing the pump to accelerate rapidly to the speed at which the emergency trip acts....

- Liquid ring pump- Nash rotary liquid ring pumps

Nash rotary liquid ring pumps, in association with atmospheric air ejectors, may be used instead of diffuser-type steam ejectors and are arranged as shown...

- The Weir electro-feeder - a multi-stage centrifugal pump

A multi-stage centrifugal pump mounted on a common baseplate with its electric motor. The number of stages may vary from two to fourteen depending upon the capacity of the pump and the required discharge pressure....

- Feed water heaters for motor ships

Surface or direct contact feed heaters, play an important part in the recovery of latent heat from exhaust steam. Direct contact feed heaters are also known as de-aerators....

- Devaporizer & turbo-feed pump

If the de-aerator cannot be vented to atmosphere or to a gland condenser satisfactorily, a devaporizer is connected to the vapour outlet condensing the vapour vented with the non-condensable gases and cooling these gases before they are discharged. ...

- Typical de-aerator & Cascade trays

Normally, the de-aerator is mounted directly on a storage tank, into which the de-aerated water falls, to be withdrawn through a bottom connection by a pump or by gravity. The tank usually has a capacity....

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home || Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who ashore. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||