Home page||Ship employment

||

Various commodities carried by general cargo ships - stowage methods and precautions

Stowage methods and precautions

Cargoes should be stowed and secured in a manner that will

avoid exposing the ship and persons on board to unnecessary risk. The safe

stowage and securing of cargo depends upon proper planning, execution

and supervision by properly qualified and experienced personnel.

The planned procedures for the handling of cargo should be

agreed with berth or terminal operators in advance of loading or unloading.

In the case of dry bulk cargo (excluding grain), procedures should follow the

IMO Code of Practice for the Safe Loading and Unloading of Bulk Carriers,

with the associated IMO Ship/Shore Safety Check List. For grain there is

more detailed guidance in the International Code for the Safe Carriage of

Grain in Bulk.

Loading, stowage and securing of cargo other than bulk cargo is to

be carried out in accordance with the ship's approved Cargo Securing

Manual.

Handling various commodities on board general cargo ships need extra caution . Below is our guideline prior shipment of different cargoes ( reference only ). One must also be guided by practice of good seamanship.

Bagged Cargo (paper bags)

These should be stowed on double dunnage. Ideally the first layer should

be stowed athwartships on vessels equipped with side bilge systems. Steelwork

should be covered by brown paper or matting to prevent bags making

contact.Torn bags should be refused on loading. Canvas rope slings

should be made up in the hatchway centre to avoid dragging and bursting

bags. Hooks should never be used with paper bag cargoes.When stowing,

bag on bag stow is good for ventilation, whereas bag on half bag is poor

for ventilation but good for economical use of space.

Barrels

Stowed ‘bung’ uppermost on wood beds, in a fore and aft direction.

‘Quoins’ are used to prevent movement of the cargo when the vessel is in

a seaway. Barrels should never be stowed more than eight high.

Fig:

Bulk coal loader incorporating

centralised dust control system

Coal (bulk)

Check that bilge suctions are in working order and that limber boards are

tight fitting. Remove all spar ceiling, stow in the ’tween deck, and cover

with a tarpaulin or other similar protection. Plug ’tween deck scuppers.

Remove all dunnage and make arrangements for obtaining temperatures

at all levels if engaged on a long voyage. Ensure that the coal levels are well

trimmed and provide the compartment with surface ventilation whenever

weather conditions permit.

Copra

As it is liable to spontaneous combustion, it should be kept dry and clear

of steelwork surfaces, which are liable to sweat. Copra beetle will get into

any other cargoes which are stowed in the same compartment.

Cotton

Bales are liable to spontaneous combustion, so that the hold must be dry

and clean, free of oil stains etc. Adequate dunnage should be laid and all

steelwork covered to prevent contact with cargo.Wet and damaged bales

should be rejected at the loading port.

Hoses and fire appliances should be on hand and readily available during

the periods of loading, fire wires being rigged fore and aft.

Edible Oils

Deep tank stow, for which the tank must be thoroughly cleaned, inspected,

and a certificate issued by a surveyor.

Heating coils will be required, and these should be tested during the

period of preparation of the space. All inlets and outlets from the tank

should be blanked off. Shippers’ instructions with regard to carriage temperatures

should be strictly adhered to. A cargo log of these temperatures

should be kept. Extreme care should be taken on loading to leave enough

‘ullage’ for expansion of the oil during passage. Overheating should never

be allowed to occur, as damage to the oil will result.

Flour

Susceptible to damage from moisture or by tainting from other cargoes, it

should never be stowed with fruit, new timber or grain. Should a fire occur

during passage,‘dust explosions’ are liable from this cargo.

Fruit

Usually carried in refrigerated spaces, especially over long sea passages, it

may also be carried chilled under forced ventilation.However, regular checks

should be made on ventilation system and compartment temperatures.

This cargo gives off CO2 and will consequently require careful ventilation

throughout the voyage.

Glass (Crates)

Crates of glass should never be stowed flat, but on their edge, on level deck

space. Plate glass should be stowed athwartships and window glass in the

fore and aft line, each crate being well secured by chocks to prevent movement

when the vessel is at sea. Overstowing by other cargoes should be

avoided.

Vehicles

These should be stowed in the fore and aft line, on level deck space.They

should be well secured against pitching and rolling of the vessel by rope

lashings. Fuel tanks should be nearly empty. Close inspection should be

made at the point of loading, any damage being noted on acceptance.

Methods of cargo carriage for different commodities onboard

In general, commodities are either moved in bulk or as general cargo. Bulk and

general cargoes are defined relative to their means of transport and the cargo mix

onboard. If, for example, a ship carries a homogeneous cargo lot which is not packed

in any form, this is a bulk cargo: oil carried directly in tanks, grain carried directly in

holds or pig iron loaded directly, in holds.

When cargoes are packed and mixed onboard, it is referred to as general cargo. Most

finished goods are shipped as general cargo, while raw materials in bigger lots are

usually bulk cargoes.

The distinction between bulk cargoes and general cargoes is not strict. There are

examples of more than one bulk cargo being carried onboard the same ship, in

different holds or sections. Similarly, there are general cargoes which fill up the whole

carrier, e.g. shiploads of sugar in bags. This is referred to as unit loads of general

cargoes (which does not necessarily involve pallets or containers). The opposite,

where the ship carries different cargoes packed differently is referred to as general

break bulk cargoes. Such cargoes may consist of pallets, unpacked machinery, drums,

crates and so on.

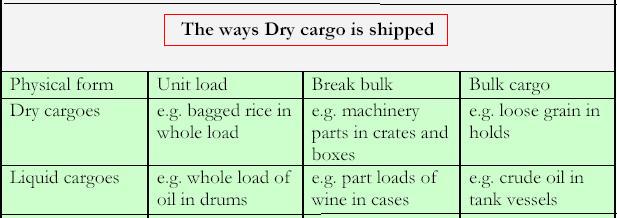

The table below clarifies the difference between the physical form of a cargo and the

way it is shipped.

Commodities, dry as well as liquid, may be shipped in unit loads, in

break bulk or as bulk cargo. It should be noted that terminology with regard to the

above is not fully consequent, and that additional terms are in use. The term "parcel

bulk" in chemical carriers is one example of this; up to 30 different chemicals may be

transported simultaneously onboard the same ship.

There exists a third; “hybrid” form of moving

cargoes, involving slurry techniques. Dry bulk

cargoes may be transformed into slurries and moved

in a form similar to that of liquid bulk. This has been

applied to coal and iron ores, where the ores or the

coal are mixed with water and transported by means

of pipelines.

On a world wide basis, almost all the liquid

commodities, measured in tons, are moved in bulk.

Important dry goods, like grain, coal, ores, tapioca,

copra and salt are similarly moved in homogeneous unpackaged lots. Such bulk

cargoes can be handled in many different ways. Liquids are moved in pipelines, grain

are mostly loaded by conveyors or chutes and unloaded pneumatically, while ores and

coal are mostly moved with conveyors or grabs.

The cargo characteristics will influence the choice of ship needed for a specific job.

Different ships are constructed to carry different bulk cargoes.

Similarly, the cargo access equipment have been constructed to cater for different

commodities. The equipment available for cargo handling at the intended ports of

loading and discharge will also be reflected in the type of ship needed for a specific

job. If, for example, no cranes are available in the discharging port, a ship equipped

with cranes will have to be chosen for the transport task.

Summarized below some more details on general cargo ship cargo handling procedure and operational info:

-

Cargo handling procedure for general cargo ship

Suitable safety nets or temporary fencing should be rigged where personnel have to walk or climb across built-up cargo, and are therefore at

risk of falling .

More .....

-

Various cargo handling techniques

(a) Technological advances in ship design and lifting equipment

(b) Rapid development and increase in the tonnages of bulk cargo

(c) The impact of unitisation, and

(d) The new and modern techniques of refrigeration, particularly with container

carriage.

More .....

-

Cargo information rules

The MS (Carriage of Cargoes) Regulations 1999 (SI 1999/336) [Regulation 4(1)] specifies that the shipper must provide such information to the operator or master sufficiently

in advance of loading to enable them to ensure that:

• the different commodities to be carried are compatible with each other or suitably separated;.

More .....

-

Cargo packaging - general cargo ships procedure

To achieve compatibility between cargo

owners and the owners of the means of

transport requires knowledge of the

cargo-handling procedures in transport.

These procedures are described with

reference to major characteristics of

commodities and cargoes. .

More .....

-

Cargo stowage plan

The copies are forwarded to agents at ports of

discharge to allow the booking and reservation of labour, as appropriate. Relevant details of cargoes, i.e. total quantity, description of package, bales, pallets etc., tonnage, port of discharge,

identification marks and special features if and when separated .

More .....

-

Shipment procedure for cargoes in different forms

General cargo is a term that covers a great variety of goods. In regard to modern

cargo handling it refers to loose cargo that has not been consolidated for handling

with mechanical means such as unitised or containerised cargo. It refers to individual

items of any type of cargo, bagged or baled items, cases or crates, individual drums or

barrels pieces of machinery or small items of steel construction. .

More .....

-

Information exchange on cargo stowage and planning

Advance planning, exchange of information, and continuous ship to shore communication are all critical. All cargoes should be stowed and secured in a manner that will avoid exposing the ship and persons on board to unnecessary risk.

More .....

-

Lifting and carriage of deck cargo

The safe securing of all deck cargoes should be checked by a

competent person before the vessel proceeds on passage. The master is

responsible for ensuring that it is correctly stowed and adequately secured

for the intended voyage. Areas on the deck which are not to be used for

cargo stowage should be clearly marked or otherwise indicated. .

More .....

-

Safe use of pesticides on board cargo ships

Ship's personnel should not handle fumigants and such operations

should be carried out only by qualified operators. Fumigation should only be

carried out with the agreement of the ship's master..

More .....

-

Types of packaging & stowage methods for break bulk cargo

The rigging time being negligible, and the crane is able to pick up and land permitted loads anywhere within its working radius. .

More .....

-

Various commodities carried by general cargo ships

Cargoes should be stowed and secured in a manner that will

avoid exposing the ship and persons on board to unnecessary risk. The safe

stowage and securing of cargo depends upon proper planning, execution

and supervision by properly qualified and experienced personnel. .

More .....

-

Methods of ventilation

The holds of most dry cargo ships are ventilated by a mechanical supply and natural exhaust system

.

More .....

-

Carriage of containers on cargo ships

The process of loading and securing

of goods into a container should follow the IMO/ILO/UN/ECE Guidelines

for Packing of Cargo Transport Units (CTUs). Special care should be taken

when lifting a container the centre of gravity of which is mobile, e.g. a tank

container, bulk container or a container with contents which are hanging..

More .....

-

Working in cargo spaces safely

Safety arrangements prior to working cargo should ensure that

adequate and suitable lifting plant is available, in accordance with the register

of lifting appliances and cargo gear, .

More .....

-

Cargo handling procedure for general cargo ship

Suitable safety nets or temporary fencing should be rigged where personnel have to walk or climb across built-up cargo, and are therefore at

risk of falling .

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||