Home page||Ship employment

||

Methods of ventilation used in general cargo ships

Ventilation requirement

Not every commodity requires or even benefits from ventilation during transport. Cargo loaded in bulk

carriers may only benefit from surface ventilation, i.e. a change of air between the underside of the deck or

hatch above and the surface of the commodity. It follows that if there is a problem within the stow, such as

pockets of moisture, ventilation will have little effect.

Ventilation of cargo may be necessary to remove heat, dissipate gas, help prevent condensation and/or

remove taint. Heat may be generated by live fruit, wet hides, vermin, and commodities liable to spontaneous

combustion. Gases which may require dissipation include inflammable and explosive gases such as those

emitted by coal, vehicle exhausts in Ro-Ro ships, CO2 and ethylene from ripening fruit and vegetables.

Condensation appears in two basic forms, i.e. ship sweat and cargo sweat. The former appears as beads of

moisture condensing on the ship's metalwork and, typically, might occur on the side of the hold when the

sea temperature falls and reduces the adjacent metal temperature below the dew point of the surrounding

air. Similarly, cargo sweat forms on the surface of the cargo when its temperature is below the dew point of

the air adjacent to it.

The removal of existing or residual taint by means of ventilation may be carried out in conjunction with

an ozonating unit and may be required to reduce the probability of sensitive cargo becoming affected by the

taint, or to improve working conditions for labour.

The proper ventilation of holds therefore, is indispensable to the correct carriage of some goods, and may

assist in the preservation of the ship's structure itself. Sometimes with coal cargoes and those which give off

inflammable and explosive gases, or are liable to spontaneous combustion, it may be absolutely necessary

for the safety of crew and ship.

A well designed system of ventilationnatural or mechanicalaims at inducing a constant circulation of

air throughout the holds and the mass of cargo by which heat, moisture, fumes, vapours, gases and odours

given off by the cargo are discharged into the open air and replaced by air of a dew point suitable to the

prevailing conditions. Three systems of ventilation are in general use:

- a. The natural ventilation of ordinary cargo compartments, supplemented in certain cases by

modified mechanised air circulating systems.

-

b. The temperature control system of circulating air in insulated compartments, controlling its

temperature and the carbon dioxide content given off by certain commodities .

-

c. Mechanical ventilation in cargo spaces and control of humidity in the compartment.

The principle of most of these types of mechanical ventilation is to reduce the dew point of

air in ships' compartments by de-humidification to the point at which ships' sweat and cargo

sweat cannot occur. No attempt is made to change the temperature condition in the holds, the

whole object being to control the dew point of the air surrounding the cargo.

Correct ventilation can keep cargo in good condition in the great majority of circumstances if properly

employed. No system of ventilation can prevent damage if the ship's officers do not know when to and

when not to use it. Also, of course, stowage of the cargo must be correctly planned with regard to the various

classes of commodities of which it is composed, together with proper dunnaging and positioning to ensure

that the ventilation reaches all the necessary cargo.

Open-top, open-sided and flatrack containers may sometimes be stowed with cargo requiring ventilation

while on board, e.g. fruit, vegetables, spices, etc. If stowed on deck then it must be ensured that adequate

ventilation can reach the contents while properly protecting them from rain and spray. Additionally, the

container should be stowed on deck in such a position that the tilt is protected against damage from wind

and waves during the passage. Under deck, the stowage position should be so situated as to take maximum

advantage of any mechanical ventilation and care should be exercised against cross-taint, e.g. a container of

wet hides might leak strong-smelling brine.

When to Ventilate Some Guidelines

Ventilate if the dew point of the air is lower than the dew point of the cargo space. The changing air will

ventilate the cargo space and there should be little danger of condensation.

Restrict ventilation if the dew point of the outside air is higher than the temperature of the cargo.

To ventilate under such conditions would cause danger of condensation on cargo as the outside air with

higher dew point comes into the cargo space.

When the vessel is fitted with a mechanical ventilation system, the air should be re-circulated within

the cargo space when the introduction of external air is restricted. Despite this guidance special attention

must, of course, be given to conditions where cargoes are giving off fumes, etc., where according to certain

circumstances ventilation may be necessary despite the possibility of condensation. The aim should always

be to avoid stowage of cargo requiring different ventilation treatment within the same compartment. Similarly

two compartments with different ventilation requirements should effectively be sealed off from each other.

It is often required that cargo normally of a very dry nature, e.g. milk powder, casein, etc., has to be

stowed in compartments adjacent to hard frozen chambers. Experience has shown that the most effective

method of carrying cargo under these conditions is to restrict the ventilation completely during the passage.

In some refrigerated vessels, decks or bulkheads are fitted with thermal injection. The principle of such

being to provide a heat input equal and opposite to the heat loss from the refrigerated compartment.

The fitting of this equipment is of considerable value in ensuring safe out turn of cargoes stowed under such

conditions, but does not warrant departure from the basic principles of ventilation.

The importance of maintaining a dry ship and dry cargo cannot be over emphasised. The cargo should

be protected from all unfavourable exposures of temperature and moisture from the point of origin to the

delivery and the shipowner, for his own protection, should know thoroughly the history of the products

delivered to his charge and of the condition in which they are received. Typical of this category is the

carriage of perishables in open top and open side containers. It is often the practice for the tilts of these

containers to be left open while stowed below decks to improve the ventilation.

These covers should be replaced and secured at time of (or prior to) discharge. Similarly, when loaded,

the ship's staff should check the appropriate covers are drawn back to take maximum advantage of under

deck ventilation. When terminal staff have adjusted covers for the same purpose during the container dwell

time at the terminal, it is important that ship's staff and terminal staff liaise to maintain the weathertight

integrity of these containers while at the same time affording the contents maximum ventilation.

The responsibility of the terminal operator includes protection of the cargo on the wharf awaiting loading,

in so far as practical conditions permit. Stowage, subject to the same limitations, should provide the most

advantageous condition in the ship. Through an understanding of what takes place within a loaded ship, the

officers can reduce sweating hazards and provide intelligent operation or sealing of ventilation systems.

There are two options in meeting the problem of cargo sweat: the control of the dew point in all parts of

the loaded cargo space or the tempering of the cargo to keep it above the dew point of the air to which it may

be exposed while at sea or at warm ports of call or at its destination. As an example, canned condensed milk

is sometimes shipped in a warm condition out of temperate latitudes so that cargo sweat has less chance of

occurring during the passage through warmer climates.

Ship sweat may be prevented by air conditioning systems efficiently designed and efficiently operated.

Air conditioning plants are not the panacea for all ills and unless the cargo being served by them is delivered

in temperatures above the dew point of the air at the port of delivery, there is no guarantee that condensation

will not occur.

The temperature of the air both outside and in different cargo compartments should be regularly taken

and recorded. It is of utmost importance that attention to the ventilation of cargo be clearly and regularly

recorded in the Deck Log with special mention made of any opening of hatches, etc. The absence of such

records may result in large claims for alleged neglect.

In most ships a combination of natural and mechanical ventilation is

provided in the accommodation and machinery spaces. Mechanical supply

is common, and a natural exhaust may be permitted in a number of compartments;

but where fumes, etc., are present, for example from galleys, a

mechanical exhaust is required. This is also the case with many public

rooms, often crowded and where smoking is permitted. The mechanical

supply is by means of light steel sheet trunking, with louvres at each outlet.

Fans may be of the quiet running centrifugal type with a separately mounted

motor.

The holds of most dry cargo ships are ventilated by a mechanical supply

and natural exhaust system. Here the object is to reduce the hold temperatures

if necessary and prevent large amounts of condensation accumulating

on the hull and cargo. Often the cargo hold fans which are of the axial type

are located in the mast houses, although they have been positioned in

derrick posts where these posts are used to ventilate the tweens and holds

.

Dry cargo ships may also be fitted with de-humidification

facilities, controls being provided so that each hold can be supplied with dry

air or outside air. If dry air is desired when the weather dew-point approaches

or is above the temperature in the hold, the air supply or recirculating air

may be drawn through a conditioning plant where it comes into contact with

a moisture absorbing solution. A dry air fan then passes this de-humidified

air to the cargo hold ventilation system.

Air conditioning is a common feature in the accommodation of modern

ships. Room temperatures are controlled by a thermostat, heated or chilled

air may then be supplied as required and humidity control is also provided.

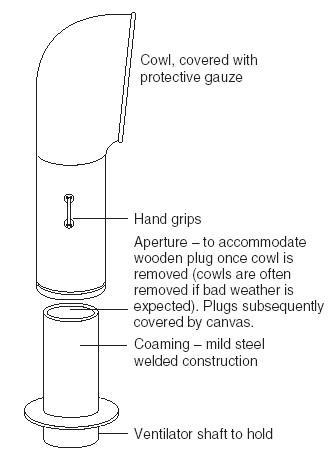

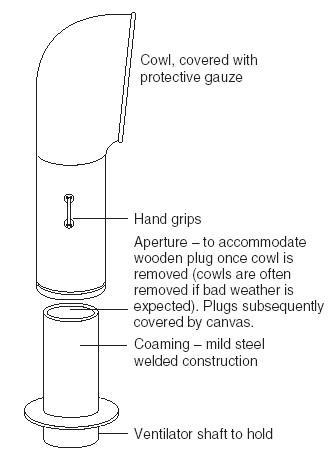

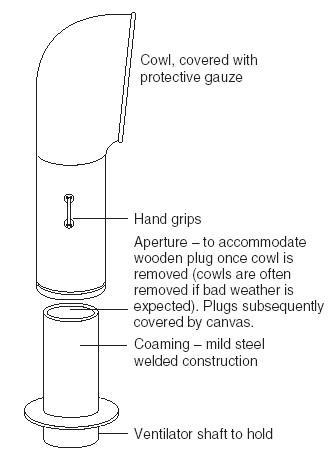

Cowl ventilators

Natural Ventilation method

In natural ventilation method , cowls

are trimmed into the wind to take in outside air, and trimmed back to

wind to allow the air circulation an exit from the hold. Fans may be incorporated

into this cowl ventilator system especially for the lower hold

regions where fans assist delivery and air extractors assist the exhaust system.

Cowls may also be fitted with manually operated closure flaps.

Forced Ventilation method

More recent developments in ventilating systems have led to air being predried

before entering the hold. In some cases the temperature of the air as

well as its humidity may be controlled before entering the compartment

.This artificial or forced ventilation, has become increasingly

popular because, when properly used, it can almost prevent any sweat

damage to cargo.

Summarized below some more details on general cargo ship cargo handling procedure and operational info:

-

Cargo handling procedure for general cargo ship

Suitable safety nets or temporary fencing should be rigged where personnel have to walk or climb across built-up cargo, and are therefore at

risk of falling .

More .....

-

Various cargo handling techniques

(a) Technological advances in ship design and lifting equipment

(b) Rapid development and increase in the tonnages of bulk cargo

(c) The impact of unitisation, and

(d) The new and modern techniques of refrigeration, particularly with container

carriage.

More .....

-

Cargo information rules

The MS (Carriage of Cargoes) Regulations 1999 (SI 1999/336) [Regulation 4(1)] specifies that the shipper must provide such information to the operator or master sufficiently

in advance of loading to enable them to ensure that:

• the different commodities to be carried are compatible with each other or suitably separated;.

More .....

-

Cargo packaging - general cargo ships procedure

To achieve compatibility between cargo

owners and the owners of the means of

transport requires knowledge of the

cargo-handling procedures in transport.

These procedures are described with

reference to major characteristics of

commodities and cargoes. .

More .....

-

Cargo stowage plan

The copies are forwarded to agents at ports of

discharge to allow the booking and reservation of labour, as appropriate. Relevant details of cargoes, i.e. total quantity, description of package, bales, pallets etc., tonnage, port of discharge,

identification marks and special features if and when separated .

More .....

-

Shipment procedure for cargoes in different forms

General cargo is a term that covers a great variety of goods. In regard to modern

cargo handling it refers to loose cargo that has not been consolidated for handling

with mechanical means such as unitised or containerised cargo. It refers to individual

items of any type of cargo, bagged or baled items, cases or crates, individual drums or

barrels pieces of machinery or small items of steel construction. .

More .....

-

Information exchange on cargo stowage and planning

Advance planning, exchange of information, and continuous ship to shore communication are all critical. All cargoes should be stowed and secured in a manner that will avoid exposing the ship and persons on board to unnecessary risk.

More .....

-

Lifting and carriage of deck cargo

The safe securing of all deck cargoes should be checked by a

competent person before the vessel proceeds on passage. The master is

responsible for ensuring that it is correctly stowed and adequately secured

for the intended voyage. Areas on the deck which are not to be used for

cargo stowage should be clearly marked or otherwise indicated. .

More .....

-

Safe use of pesticides on board cargo ships

Ship's personnel should not handle fumigants and such operations

should be carried out only by qualified operators. Fumigation should only be

carried out with the agreement of the ship's master..

More .....

-

Types of packaging & stowage methods for break bulk cargo

The rigging time being negligible, and the crane is able to pick up and land permitted loads anywhere within its working radius. .

More .....

-

Various commodities carried by general cargo ships

Cargoes should be stowed and secured in a manner that will

avoid exposing the ship and persons on board to unnecessary risk. The safe

stowage and securing of cargo depends upon proper planning, execution

and supervision by properly qualified and experienced personnel. .

More .....

-

Methods of ventilation

The holds of most dry cargo ships are ventilated by a mechanical supply and natural exhaust system

.

More .....

-

Carriage of containers on cargo ships

The process of loading and securing

of goods into a container should follow the IMO/ILO/UN/ECE Guidelines

for Packing of Cargo Transport Units (CTUs). Special care should be taken

when lifting a container the centre of gravity of which is mobile, e.g. a tank

container, bulk container or a container with contents which are hanging..

More .....

-

Working in cargo spaces safely

Safety arrangements prior to working cargo should ensure that

adequate and suitable lifting plant is available, in accordance with the register

of lifting appliances and cargo gear, .

More .....

-

Cargo handling procedure for general cargo ship

Suitable safety nets or temporary fencing should be rigged where personnel have to walk or climb across built-up cargo, and are therefore at

risk of falling .

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||