Home page||Fire protection||

Halon system for Ship fire protection

Halon systems

Halons are included in the Montreal protocol as gases with ozone depletion

potential (ODP) and must not be specified for use in fixed fire fighting

installations. Compared with R12 which has been assigned an ODP of I, Halon

1211 has been given an ODP of 3 and Halon 1301 a figure of 10. Existing fixed

halon fire protection systems will need a replacement fire fighting medium for

which adaptations will be required.

Halon systems with Halon 1301 have been fitted to a large number of ships.

Halon is the name for halogenated compounds made by the replacement ot

hydrogen in methane or ethane with one of the halogens. Fluorine, chlorine

and bromine are halogens.

Halon 1301 has the chemical formula CF3 Br being known as bromo-trifluoromethane.

It is a colourless, odourless gas with a density five times that of air and

extinguishes fire by breaking the combustion chain reaction.

Other halogenated hydrocarbons such as methylbromide and carbon

tetrachioride have been used in the past as fire extinguishing agents but have

been banned by various authorities because of their extremely toxic nature.

Halon 1301 however, is classed by Underwriters Laboratories as least toxic'

(Group 6) and properly applied discharges of the gas allow people to see and

breathe permitting them to leave the fire area with some safety.

It must be pointed out however, that when Halon 1301 is exposed to flame

or hot surfaces above 480°C halogen acids and free halogens having a higher

level of toxicity are produced. A self- contained breathing apparatus or a fresh

air mask is therefore essential equipment when entering a space which has been

flooded with Halon 1301.

In some small machinery spaces Halon 1301 systems may be found in which

the Halon is stored in a sphere within the machinery space. In larger

installations the storage battery is similar to that used in CO2 systems. The gas

may be stored in 67 litre cylinders at a pressure of 40 bars. This equates to 75 kg

of Halon 1301.

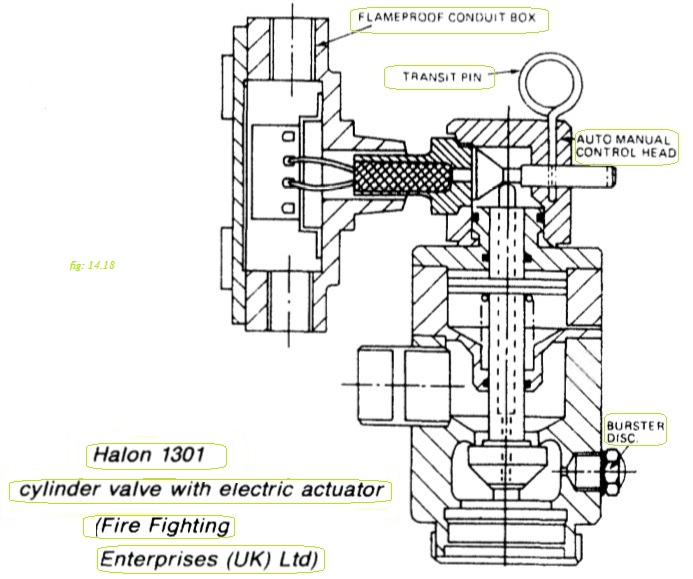

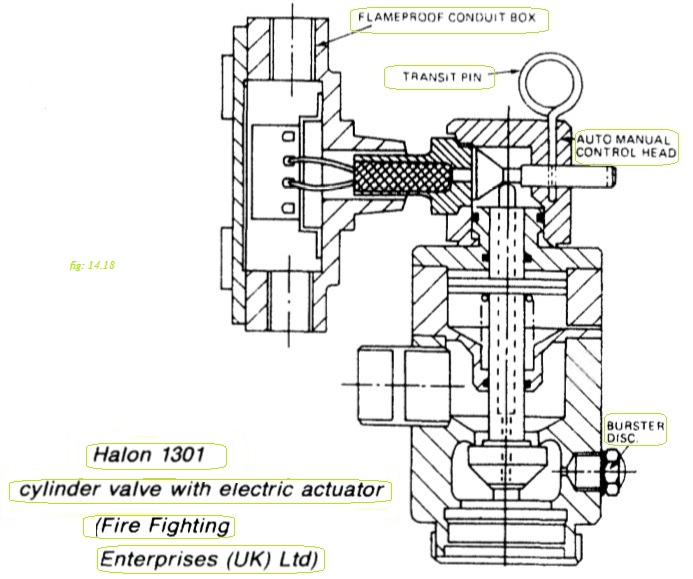

Figure : Halon 1301 cylinder valve with electric actuator (Fire Fighting

Enterprises (UK) Ltd)

Figure 14.18 shows the release gear used by Fire Fighting Enterprises (UK)

Ltd. In this system a cam on the end of the horizontal pin pushes the vertical

valve rod downwards, when the pin is actuated. The pin may be moved by a

pull wire or by one of a range of electrically or pneumatically operated actuators.

As soon as the valve rod opens the cylinder valve, gas from the cylinder is

admitted to the top side of the piston and holds the valve open. When the gas

pressure falls away a spring below the piston re-seats the valve. Only one

cylinder needs to be fitted with the horizontal pin, shown in the illustration.

The valves on the other cylinder can be linked to it with small bore copper pipe

so that gas from the master cylinder opens all of the other valves simultaneously.

Most halon cylinders are fitted with pressure gauges so that leakage can be

more readily detected. The cylinders are also fitted with bursting discs

Halon system operation

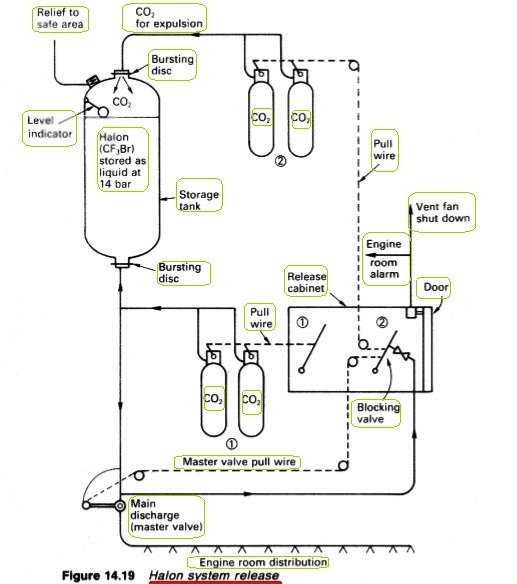

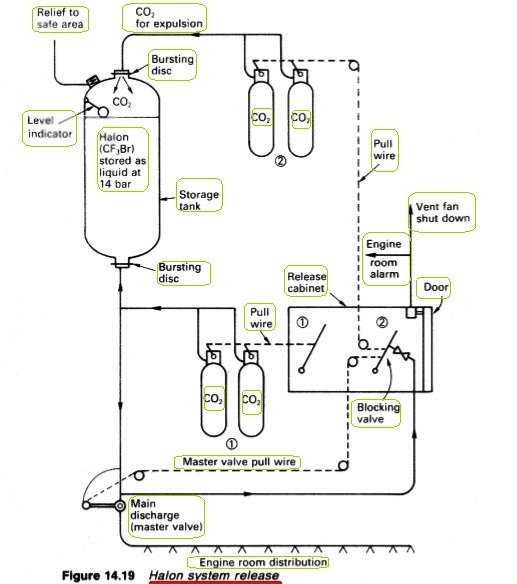

The halon release arrangement shown in Figure 14.19 consists of a storage

tank, two sets of CO2 operating cylinders and a manual release cabinet. The

halon is stored at a pressure of 14 bar in the holding tank, which has a pressure

relief, filling valve and level-indicator.

Release procedure is much the same as for COr When the cabinet is opened,

the alarm operates, fans stop and dampers or vent flaps will close. With all

entrances closed, the handles (1) and (2) are operated in succession. Handle (2)

can only be moved when released by the blocking mechanism.

The contents of the CO2 bottles opened by handle (1) pressurize the pipeline

between the halon tank and the master valve causing the bursting disc to

rupture and allowing the halon to flow as far as the master valve. The pressure

build up in this line acts on the blocking device to permit operation of handle

(2). The latter opens the master valve to the engine room distribution pipe and

also opens the CO2 bottles (2). CO2 from these ruptures the bursting disc at the

top of the storage tank and then assists in expelling the halon.

The discharge must be completed in 40 seconds but the alarm sounds as the

cabinet door is opened. Personnel must evacuate the space when warned. The

5% concentration gives a risk because the gas is toxic and must be treated with

the caution as CO2.

Figure : Halon system release

Portable halon extinguisher

The use of halon in portable extinguishers should be discontinued when suitable alternatives are available because of the high ozone depletion potential.

Summarized below general cargo ship fire protection equipments & guideline:

- Fire main system & related mechanism

The fire main

extends to the full length of the ship and from the machinery spaces to the

highest levels. Hydrants served by the main, are situated so that with suitable

hoses any area on the ship can be reached.

.....more

- CO2 fire extinguishing installation

Fire extinguishing installations employing CO2 stored under pressure at

ambient temperature are extensively used to protect ships' cargo compartments,

boiler rooms and machinery spaces. When released the CO2 is distributed

throughout the compartment, so diminishing the relative oxygen content and

rendering the atmosphere inert.

...... more

- Fire fighting equipments

Two independently powered pumps must be provided in all cargo ships of 1000 tons gross and over and in passenger ships of less than 4000 tons gross. Larger passenger vessels and passenger ferries must have three such pumps. The pumps are fitted with non-return valves if they are of the centrifugal type, to prevent loss of water back through open valves when not running.

..... more

- Details of fire detectors

A variety of devices are available for detecting fire in unmanned machinery

spaces but each has an ability to detect basically only one aspect. Thus, smoke

detectors based on the ionization chamber are able to recognize combustion

products but will not register radiation from a flame or heat.

.....more

- Machinery space fire & use of Walter Kidde CO2 system

Walter Kidde CO2 system employs pilot

CO2 cylinders to open the distribution system main stop valve and

subsequently the valves on the individual CO2 cylinders.

.....more

- Fire protection system for cargo holds

Holds for general cargo, have been protected against fire by fixed installations which deliver inert gas from an inert gas generator based on combustion of fuel (similar to the system available for inerting oil tankers) and halon systems.

.....more

- Low pressure CO2 storage

In some installations, the CO2 is stored in low pressure refrigerated tanks. The

cylindrical storage vessels are fabricated to the pressure vessel

requirements of the authorities. The tanks are of low temperature steel, fully

tested and stress relieved. They are mounted on supports designed to

withstand shock from collision.

..... more

- Halon system

Halon 1301 has the chemical formula CF3 Br being known as bromo-trifluoromethane.

It is a colourless, odourless gas with a density five times that of air and

extinguishes fire by breaking the combustion chain reaction.

.....more

- Multi-spray system for the machinery spaces

This system is similar to the sprinkler used in accommodation areas but the spray heads are not operated automatically. The section control valves (Figure 14.20) are opened by hand to supply water to the heads in one or more areas. Ready to use hoses can also be supplied. Fresh water is used for the initial charging and the system is brought to working pressure by means of the compressed air connection.

.....more

- Automatic sprinkler system

A network of

sprinkler heads is arranged throughout the spaces to be protected. Each sprinkler head is normally kept closed by a quartzoid bulb which is almost filled with a liquid having a high expansion ratio.

.....more

- Details various portable extinguishers & how to use ?

The first line of defence against fire in any area of the ship, is the portable fire extinguisher. Some common portable extinguishers that have been used at sea are described.

.....more

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||