Home page||Fire protection||

Fire fighting equipments for general cargo ship

Fire pumps

Two independently powered pumps must be provided in all cargo ships of

1000 tons gross and over and in passenger ships of less than 4000 tons gross.

Larger passenger vessels and passenger ferries must have three such pumps.

The pumps are fitted with non-return valves if they are of the centrifugal type,

to prevent loss of water back through open valves when not running.

A relief

valve is necessary in the system if the pumps are capable of raising the pipeline

pressure so that it is greater than the design figure. With centrifugal pumps the

relief valve is unlikely to be needed but it is essential for a positive

displacement fire pump. Minimum line pressures and capacities are governed

by the regulations. Whilst fire pumps may be used for other duties such as

ballast or general service they should not normally be used for pumping oil.

Changeover arrangements may be fitted allowing a pump to be used for oily

bilge

Emergency fire pump

Normally, cargo vessels are provided with emergency fire pumps because a fire

in the engine room could put all of the other pumps out of action. Such a pump

is located away from the engine room in the

shaft tunnel, steering gear or in the forward part of the ship. The suction lift of

any pump is limited and for this reason emergency fire pumps are restricted to

being at a maximum of 6 m from the water level at light draught conditions.

Ideally they are installed below the waterline to guarantee avoidance of suction

problems. There have been difficulties in the past with some steering gear

located emergency fire pumps when the ship was in the ballast condition.

If the location of a centrifugal type emergency fire pump is the steering flat

then, because of the high suction lift involved, a priming pump is fitted. This

may be friction driven from the fire pump flywheel and once the fire pump is

running the priming pump drive wheel, normally held away from the flywheel

by a spring, must be held against it until the fire pump is primed. The fire pump

(centrifugal type) discharge valve is shut while the pump is being primed and

opened gradually as the suction is taken up.

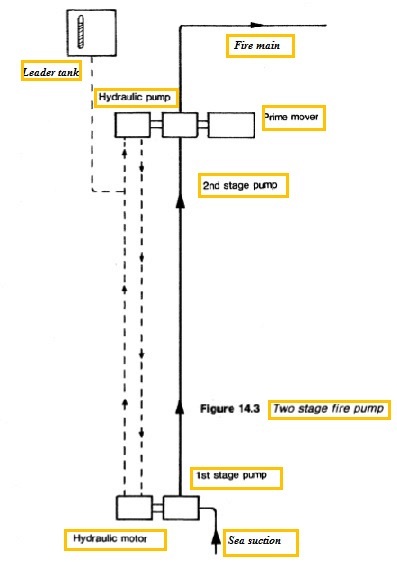

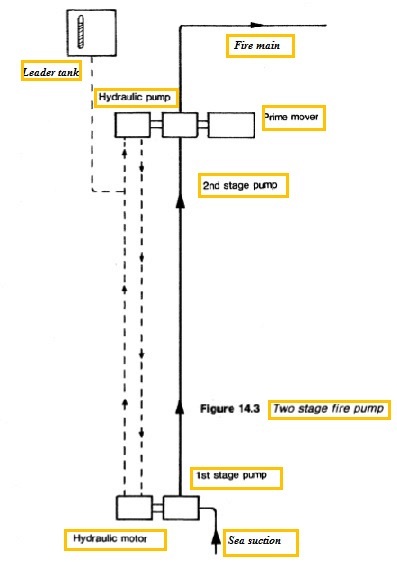

Figure : Two stage fire pump

On large vessels a special two stage pump arrangement may be used

(Figure 14.3) The first stage below the waterline is driven by a hydraulic motor.

The second stage and the hydraulic power unit are driven by a prime mover (or

electric motor from the emergency supply) which can be positioned at more

than the normal distance from the waterline.

If the fire pump is driven by a water-cooled diesel engine supplied with

cooling water from the fire pump a header tank will be provided to ensure that

the engine is cooled while the fire pump is being primed. The engine could

have a closed circuit fresh-water system, with the water being cooled in a

radiator. It is usual however, to fit an air-cooled diesel engine.

Where a closed-circuit fresh-water cooled engine is installed anti-freeze may

be needed for the radiator in cold weather.

An emergency pump has an independent diesel drive or some alternative

such as an electric motor powered from the emergency generator.

Pipelines

Where steel pipes are used, they are galvanized after bending and welding.

Their diameter is between 50 mm and 178 mm depending on the size and type

of ship. Engine room hydrants must have hoses and nozzles for jet and fog or

dual purpose nozzles.

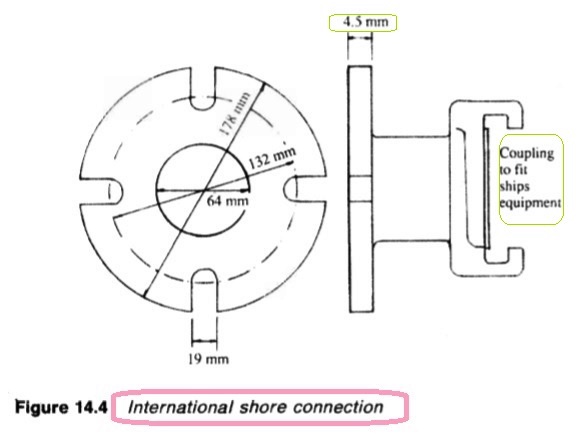

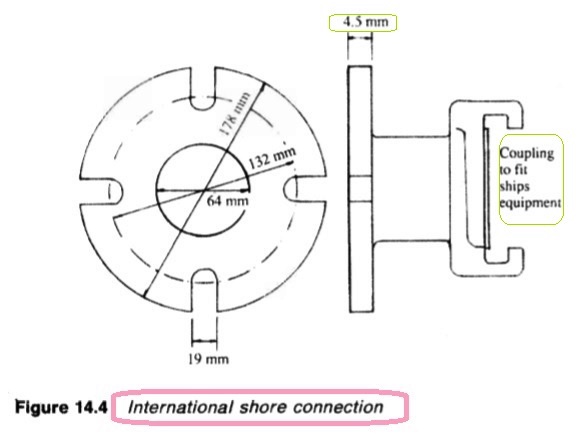

International shore connection

The international shore connection (Figure 14.4) is a standard sized flange with

nuts, bolts and washers and a coupling for the ship's fittings. The dimensions

are shown. The fitting and joint must be suitable for a working pressure of at

least 10.5 bar.

Four bolts are required of 16mm diameter and 50mm length, also eight

washers.

Figure : International shore connection

Hoses and nozzles

Fire hoses must be of approved materials. They are positioned adjacent to

hydrants together with suitable nozzles. Dual purpose nozzles can be adjusted

by rotation of the sleeve to produce a jet or spray. These are an alternative to

having available separate jet and spray or fog nozzles.

Foam adaptor

Foam branch pipes (Figure 14.5) which operate in a similar manner to those

used in deck installations for tankers, are fitted for use with the hydrants in

some machinery spaces and in particular for passenger ferry car decks. These

are available in various sizes for operation at a range of pressures and outputs.

Figure : Chubb fire FB5X foam making branch pipe (Chubb Fire

Security Ltd)

The foam branch pipe is connected through a hose to the hydrant and the water

flow produces a venturi effect which draws up the foam producing liquid

through the pick-up tube, from the container. The action also draws in air.

Mixing of the three components in the nozzle, causes formation of a jet of

foam. Initially, only water issues from the branch pipe and the nozzle is directed

away from the fire until foam appears. When the foam compound is exhausted,

water will again appear at the nozzle. Foam continuity is achieved by dropping

the pick-up tube in a bucket and keeping the bucket topped up with foam liquid,

Summarized below general cargo ship fire protection equipments & guideline:

- Fire main system & related mechanism

The fire main

extends to the full length of the ship and from the machinery spaces to the

highest levels. Hydrants served by the main, are situated so that with suitable

hoses any area on the ship can be reached.

.....more

- CO2 fire extinguishing installation

Fire extinguishing installations employing CO2 stored under pressure at

ambient temperature are extensively used to protect ships' cargo compartments,

boiler rooms and machinery spaces. When released the CO2 is distributed

throughout the compartment, so diminishing the relative oxygen content and

rendering the atmosphere inert.

...... more

- Fire fighting equipments

Two independently powered pumps must be provided in all cargo ships of 1000 tons gross and over and in passenger ships of less than 4000 tons gross. Larger passenger vessels and passenger ferries must have three such pumps. The pumps are fitted with non-return valves if they are of the centrifugal type, to prevent loss of water back through open valves when not running.

..... more

- Details of fire detectors

A variety of devices are available for detecting fire in unmanned machinery

spaces but each has an ability to detect basically only one aspect. Thus, smoke

detectors based on the ionization chamber are able to recognize combustion

products but will not register radiation from a flame or heat.

.....more

- Machinery space fire & use of Walter Kidde CO2 system

Walter Kidde CO2 system employs pilot

CO2 cylinders to open the distribution system main stop valve and

subsequently the valves on the individual CO2 cylinders.

.....more

- Fire protection system for cargo holds

Holds for general cargo, have been protected against fire by fixed installations which deliver inert gas from an inert gas generator based on combustion of fuel (similar to the system available for inerting oil tankers) and halon systems.

.....more

- Low pressure CO2 storage

In some installations, the CO2 is stored in low pressure refrigerated tanks. The

cylindrical storage vessels are fabricated to the pressure vessel

requirements of the authorities. The tanks are of low temperature steel, fully

tested and stress relieved. They are mounted on supports designed to

withstand shock from collision.

..... more

- Halon system

Halon 1301 has the chemical formula CF3 Br being known as bromo-trifluoromethane.

It is a colourless, odourless gas with a density five times that of air and

extinguishes fire by breaking the combustion chain reaction.

.....more

- Multi-spray system for the machinery spaces

This system is similar to the sprinkler used in accommodation areas but the spray heads are not operated automatically. The section control valves (Figure 14.20) are opened by hand to supply water to the heads in one or more areas. Ready to use hoses can also be supplied. Fresh water is used for the initial charging and the system is brought to working pressure by means of the compressed air connection.

.....more

- Automatic sprinkler system

A network of

sprinkler heads is arranged throughout the spaces to be protected. Each sprinkler head is normally kept closed by a quartzoid bulb which is almost filled with a liquid having a high expansion ratio.

.....more

- Details various portable extinguishers & how to use ?

The first line of defence against fire in any area of the ship, is the portable fire extinguisher. Some common portable extinguishers that have been used at sea are described.

.....more

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||