Home page||Fire protection||

Automatic sprinkler system - Ship fire protection procedure

A number of fatal accommodation fires have been started by people falling asleep whilst smoking. The sprinkler system provides protection against this type of incident.

Automatic sprinkler systems

The combination of structural fire protection and an installed sprinkler system which incorporates detection, alarm and fire-fighting capability, has proved very successful in combating the outbreak of fire in passenger ship accommodation. The structural fire protection is based on zones separated by fire proof bulkheads and having fire proof divisions within them.

A network of

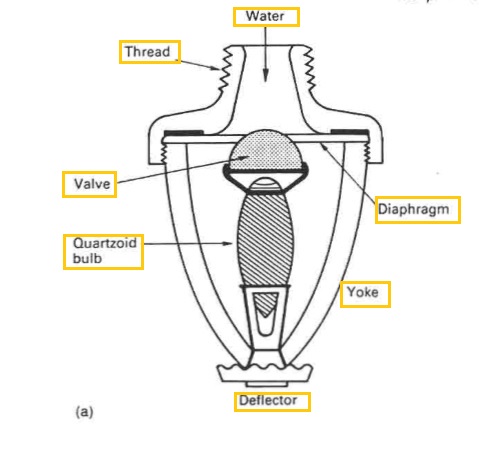

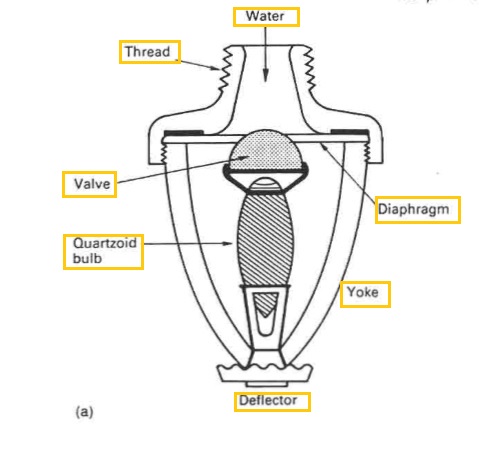

sprinkler heads is arranged throughout the spaces to be protected. Each sprinkler head (Figure 14.28a) is normally kept closed by a quartzoid bulb which is almost filled with a liquid having a high expansion ratio. When the liquid is exposed to abnormal heat it expands rapidly to completely fill the bulb. Further expansion is sufficient to shatter the bulb. Water, maintained under pressure by compressed air, is then expelled from the sprinkler head or heads in the form of a heavy spray. Each head adequately showers a deck area of 16 mz and the heads are arranged so that every part of each space requiring protection, can be covered by water spray.

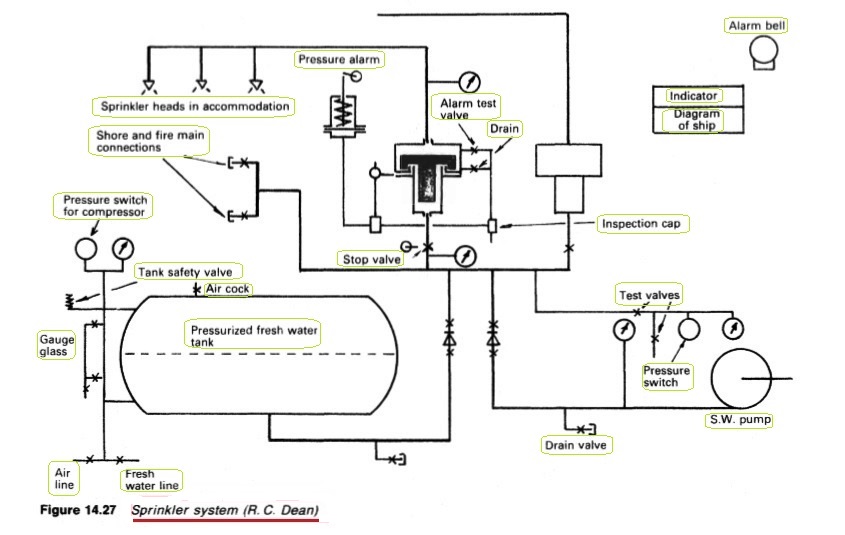

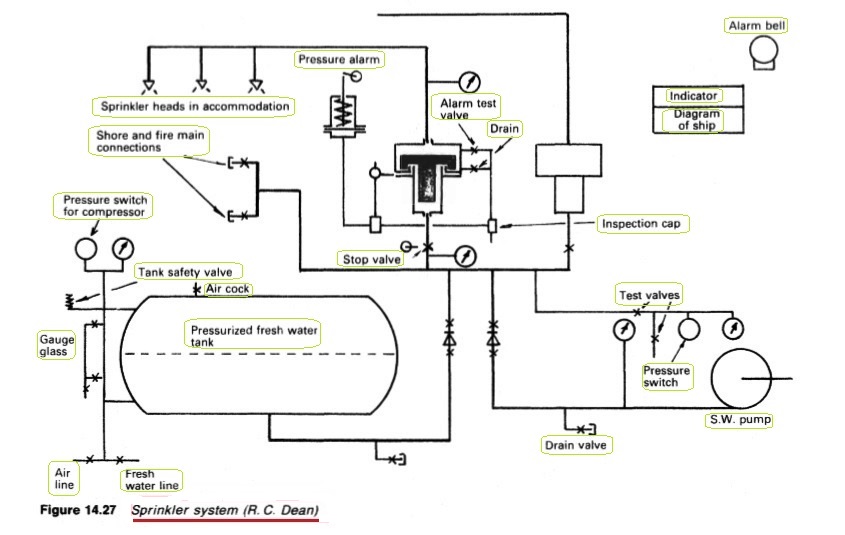

Figure : Sprinkler system (R. C. Dean)

Figure 14.27

Figure : (a) Sprinkler head;

i Figure 14.28a

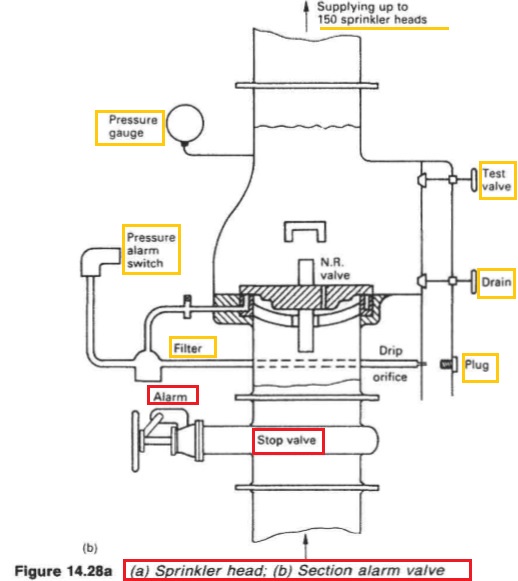

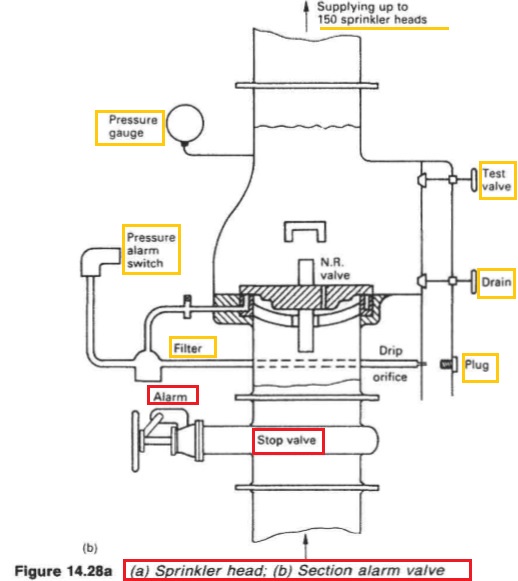

Figure : (b) Section alarm valve

The system shown (Figure 14.27) has a pressure tank which is kept part-filled with fresh water and pressurized to 8 bar by compressed air. When the pressure drops below 5.5 bar, a salt water pump cuts in automatically so that if the sprinklers operate a supply of water is maintained. Each installation is divided into sections containing up to 200 sprinkler heads and each section has an alarm valve (Figure 14.28b).

When a sprinkler comes into operation water flows through the section alarm valve. The water lifts the non-return valve exposing an annular groove which connects to a diaphragm alarm switch. This switch is coupled to an alarm and to an indicator panel on the bridge which gives audible and visual warning that a sprinkler has operated and fire has probably broken out in the section indicated.

Fires have frequently been found to have been extinguished by the system alone. When any occurrence has been dealt with the stop valve, which is usually locked open, may be closed to replace the sprinkler head which has operated and to enable the section to be drained of salt water before being filled with fresh from the system. Any maintenance on a section is carried out with the stop valve closed. The test valve can be opened to create flow and cause the non-return section alarm valve to open, to test the alarm.

Regular maintenance of the system consists of greasing the various valves and checking their freedom of movement, logging the pressure gauge reading, before and after each alarm valve (thus checking the tightness of the non-return valves) and checking the alarm system. The latter is done by opening the testvalves and checking that the audible and visual alarms work. The pressure tank level is checked and recharged, if necessary, with fresh water and air.

The centrifugal salt-water pump should also be tested by closing the isolating valves and draining the pressure switch circuit, when the pump should start automatically. Delivery pressure should be logged. In the event of a fire, when a normal situation is recovered the section and system are drained and flushed out; then recharged with fresh water and air.

Where an automatic system is not fitted in accommodation spaces, it is necessary to install an automatic fire alarm system similar to that used for unmanned machinery spaces. The system would consist of an electric circuit for srnoke detectors and possibly bimetallic temperature sensors. Warning is given by an audible alarm with visual indication showing the section in which the fire has occurred.

Summarized below general cargo ship fire protection equipments & guideline:

- Fire main system & related mechanism

The fire main

extends to the full length of the ship and from the machinery spaces to the

highest levels. Hydrants served by the main, are situated so that with suitable

hoses any area on the ship can be reached.

.....more

- CO2 fire extinguishing installation

Fire extinguishing installations employing CO2 stored under pressure at

ambient temperature are extensively used to protect ships' cargo compartments,

boiler rooms and machinery spaces. When released the CO2 is distributed

throughout the compartment, so diminishing the relative oxygen content and

rendering the atmosphere inert.

...... more

- Fire fighting equipments

Two independently powered pumps must be provided in all cargo ships of 1000 tons gross and over and in passenger ships of less than 4000 tons gross. Larger passenger vessels and passenger ferries must have three such pumps. The pumps are fitted with non-return valves if they are of the centrifugal type, to prevent loss of water back through open valves when not running.

..... more

- Details of fire detectors

A variety of devices are available for detecting fire in unmanned machinery

spaces but each has an ability to detect basically only one aspect. Thus, smoke

detectors based on the ionization chamber are able to recognize combustion

products but will not register radiation from a flame or heat.

.....more

- Machinery space fire & use of Walter Kidde CO2 system

Walter Kidde CO2 system employs pilot

CO2 cylinders to open the distribution system main stop valve and

subsequently the valves on the individual CO2 cylinders.

.....more

- Fire protection system for cargo holds

Holds for general cargo, have been protected against fire by fixed installations which deliver inert gas from an inert gas generator based on combustion of fuel (similar to the system available for inerting oil tankers) and halon systems.

.....more

- Low pressure CO2 storage

In some installations, the CO2 is stored in low pressure refrigerated tanks. The

cylindrical storage vessels are fabricated to the pressure vessel

requirements of the authorities. The tanks are of low temperature steel, fully

tested and stress relieved. They are mounted on supports designed to

withstand shock from collision.

..... more

- Halon system

Halon 1301 has the chemical formula CF3 Br being known as bromo-trifluoromethane.

It is a colourless, odourless gas with a density five times that of air and

extinguishes fire by breaking the combustion chain reaction.

.....more

- Multi-spray system for the machinery spaces

This system is similar to the sprinkler used in accommodation areas but the spray heads are not operated automatically. The section control valves (Figure 14.20) are opened by hand to supply water to the heads in one or more areas. Ready to use hoses can also be supplied. Fresh water is used for the initial charging and the system is brought to working pressure by means of the compressed air connection.

.....more

- Automatic sprinkler system

A network of

sprinkler heads is arranged throughout the spaces to be protected. Each sprinkler head is normally kept closed by a quartzoid bulb which is almost filled with a liquid having a high expansion ratio.

.....more

- Details various portable extinguishers & how to use ?

The first line of defence against fire in any area of the ship, is the portable fire extinguisher. Some common portable extinguishers that have been used at sea are described.

.....more

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||