Home page||Air conditioning ||

Air purification, Heating and cooling loads and air quantities- Marine air conditioning systems

Air purification

Outside air must be introduced to all living spaces, although the amount of fresh air necessary to sustain life is very small indeed. Space conditions can vary greatly in a short time. They are governed by factors such as body odours and smoking, which may require a fresh air supply of 12 litre/s per person or more.

The actual quantity of fresh air supplied is partially governed by the provision that it must not be less than the total capacity of the accommodation exhaust fans (excluding galley). On this basis the minimum Department of Transport requirement of 7 litre/s is usually exceeded.

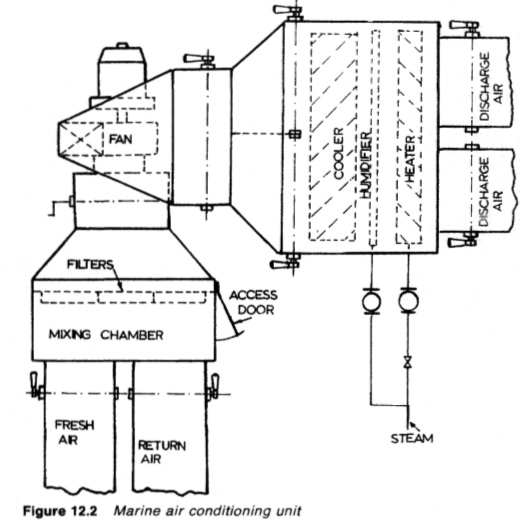

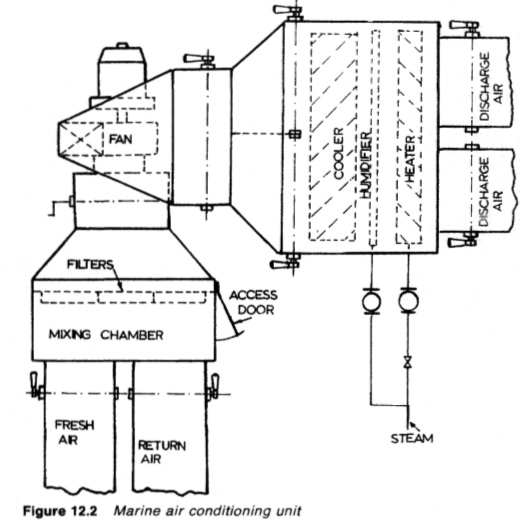

Figure : Marine air conditioning unit

Figure 12.2

It is desirable that outside air should be cleaned before being introduced to the space, but this is less essential than on land, except when the vessel is in port. Of greater influence are the impurities such as lint carried in the circulating air, which must be filtered out to prevent eventual choking of the heating and cooling elements in the conditioning plant. Filters (Figure 12.2), unless regularly cleaned can provide a breeding ground for the legionella bacteria.

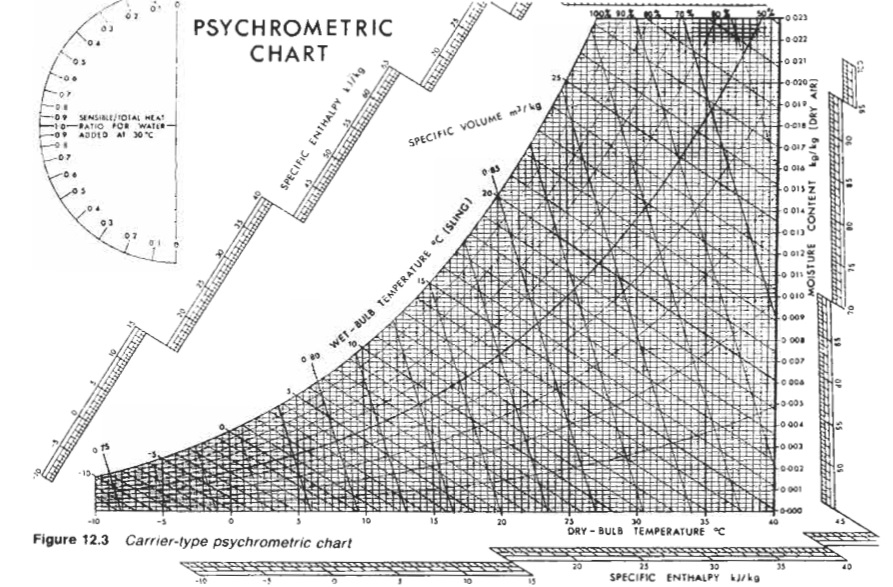

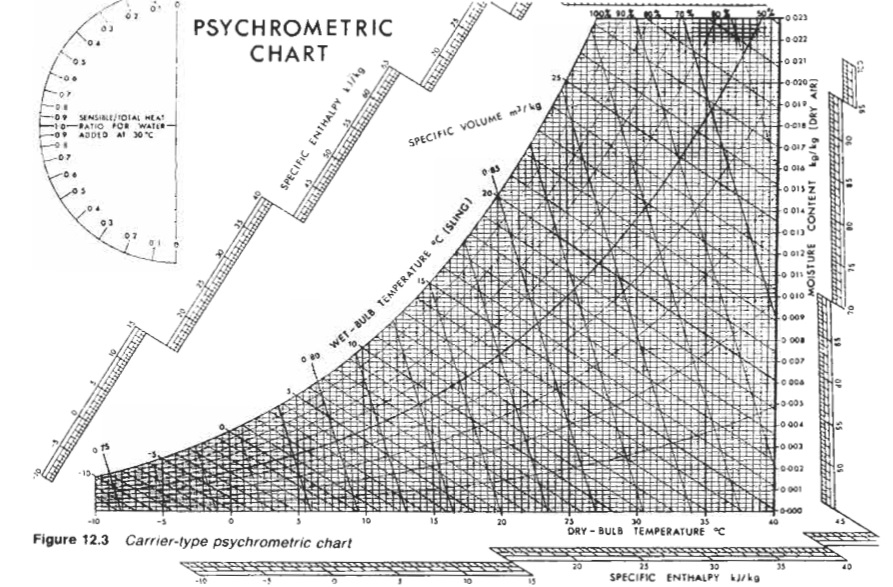

Figure : Carrier-type psychrometric chart

Cooling load

As the temperature of air is reduced, so too is its capacity for carrying water vapour. With the aid of a psychrometric chart (Figure 12.3) it can be shown that air, with an initial dry bulb temperature of 36 deg C and relative humidity of about 60%, will, when cooled to 27 deg C dry bulb temperature, have a relative humidity of 100%. The temperature drop reduces the capacity of the air to carry moisture in suspension. Further cooling will cause moisture to be precipitated.

Air cooled to a comfortable temperature level of 21 deg C but having a relative

humidity of 100% would not be able to take up further moisture and perspiration would not be evaporated. People in an atmosphere at 21 °C with 100% relative humidity would be uncomfortable.

The remedy of dehumidifying the air is achieved by overcooling to precipitate excess moisture, (removed via the drain —Figure 12.2) so that when air is brought to the correct temperature, its humidity will be at an acceptable level. Thus the air could be overcooled to about 1O°C dry bulb temperature so that warming to about 21°C, would bring humidity to about 50%.

The air is warmed in the trunking or by contact with warmer air in the space, A zone heater could be used. An adequate drain is required to remove what can be a considerable flow of water from dehumidification of the air. It can be seen that a large proportion of the total cooling load is required to reduce the moisture content of incoming fresh air and the relative humidity as well as temperature of outside air can be regarded as of the greatest significance in the specification of outside conditions for design.

Surveys have been carried out to determine the conditions over the main trade routes of the world. The figure commonly taken for outside dry bulb temperature by some designers is 32.2°C, but much higher temperatures may be experienced in tropical zones with offshore winds. These winds are, however, usually dry and do not impose as high a load on the cooling plant. Obviously local conditions will vary. It is usual to express the conditions inside the accommodation in terms of dry bulb temperature and relative humidity obtained from the psychometric chart.

Although people are not sensitive to the degree of humidity over quite a wide range, it is usual to design for between 40% and 60% relative humidity. The inside design conditions have a very important bearing on the cooling plant power.

Another very significant factor is the degree of insulation of the surfaces bounding the air conditioned spaces. At one extreme, the only insulation may be provided by decorative lining of the bulkheads and by the treatment of the engine room bulkhead, while some insulating value would lie in the deck coverings. At the other extreme, some shipowners specify generous insulation enclosing all sections of the accommodation. A reasonable mean standard would be obtained by assuming the equivalent of 25 mm of high class insulating material, having an insulating value of 1.5W/mV°C over all surfaces normally treated.

Heating load

When the temperature of air is increased, so too is its capacity for carrying water vapour. Using the psychometric chart, it can be shown that air, with a very low initial dry bulb temperature of — 5 deg C and relative humidity of about 50%, will, when heated to 21 deg C dry bulb temperature, have a relative humidity of about 10%. The temperature rise increases the capacity of the air to carry moisture in suspension. Air heated to a comfortable temperature level of 21 deg C

but having a relative humidity of 10% will readily take up moisture whether from perspiration or from the nasal passages and throat.

People in an atmosphere at 21 deg C but 10% relative humidity, would experience discomfort from dryness in their nose and throat and on the skin. The remedy is to humidify the air (Figure 12.3) with a hot water or steam spray. This action increases humidity towards 100% relative humidity and also increases the temperature from — 5°C and 50% relative humidity to say, 4- 7 deg C. Straight heating by the zone heater bringing the air to about 21°C, will drop relative humidity to 40%. The humidity will be at an acceptable level but is kept low to minimize condensation on any very cold external bulkheads.

Heating moderately cold outside air will not cause a dryness problem because it mixes with recirculated air and air in the space served. Moisture is continually added to air in accommodation areas from breathing, perspiration and other activities. The humidifier is likely to be necessary only in extremely cold conditions hence the one shown in the sketch has a simple valve for setting by hand. The heating load includes heat leakage losses through the structure, calculated with the aid of the requisite coefficients for the various materials involved, together with the heat required to raise the outside air temperature to the space temperature.

The outside temperature chosen may not be the extreme minimum for the trading routes of the vessel, but a value chosen within a range from — 20°C to 0°C. The inside condition would be from 18°C to 24°C depending upon the type of accommodation.

Evaluation of heating and cooling loads and air quantities

The cooling load has a great influence on the design of the equipment since it influences the quantity of air to be circulated and determines the size of the refrigerating plant.

The following sensible heat gains must be balanced to maintain the required inside temperature, when cooling is in operation:

- Heat transmission through the structure. This is dependent on the physical properties of the materials surrounding the air conditioned spaces and the relative humidity to be maintained inside. Allowance has also to be made for the effect of sun heat on exposed surfaces. This is very difficult to define with any accuracy, and is usually computed with the aid of tables and charts based on experience.

- Body heat. Account must be taken of the heat gain in the space due to the occupants.

- Lighting heat. This can be a significant factor on board ship, where lighting is in use almost continuously.

- Fan heat. The energy applied to the air is converted to heat in the passage of the air through the system.

The air delivered conveys the cooling effect to the spaces. This air must be delivered at a temperature below that desired in the accommodation fixed by the moisture content of the air. The air passing through the cooling coils becomes saturated on cooling and gives up moisture as its temperature falls. When the air leaves the cooler its moisture content remains unchanged until it enters the accommodation. Once inside the accommodation, the temperature of the air rises and the relative humidity (but not the moisture content) drops but it then also mixes with the resident atmosphere.

It invariably happens that this quantity is considerably greater than the fresh air requirements discussed previously, so that the balance is recirculated in order to economize in the cooling load. In practice, usually about two-thirds of the air delivered to the space is recirculated.

Summarized below some of the basic procedure of marine air conditioning system :

- Types of air conditioning system

Air conditioning systems may be divided into two main classes — the central unit type in which the air is distributed to a group of spaces through ducting, and the self-contained type, installed in the space it is to serve. .....

- Marine air conditioner

A very significant factor affecting an air conditioning system is the rapidly changing climatic conditions. The equipment has to perform within these variations and has to meet the differing requirements of the occupied spaces of the ship......

- Air conditioning central unit

The elements of a central unit are fan, filter, cooler, heaters and plenum chamber. Normally these are all housed within a single casing, with the possible exception of the fan. It is possible to carry this further by including the refrigerating plant in a single assembly thus providing a complete package. ....

- Air conditioning air terminals

The best designed air conditioning system is only as good as the means of delivering the air to the spaces. The main function of the air terminal is to distribute the air uniformly throughout the spaces without draughts......

- Heating and cooling loads and air quantities

Outside air must be introduced to all living spaces, although the amount of fresh air necessary to sustain life is very small indeed. Space conditions can vary greatly in a short time. They are governed by factors such as body odours and smoking, which may require a fresh air supply of 12 litre/s per person or more. ...

- Air conditioning unit typical specification

To prevent excessive leakage of conditioned air, all doors leading from the conditioned spaces to the outside atmosphere, machinery casing, etc., should be of the self-closing type and reasonably airtight......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||