Home page||Air conditioning ||

Types of air conditioning systems -Ship service systems

Types of air conditioning systems

Air conditioning systems may be divided into two main classes — the central unit type in which the air is distributed to a group of spaces through ducting, and the self-contained type, installed in the space it is to serve. The central unit type is the most widely used, in one or other of a number of alternative systems, characterized by the means provided to meet the varying requirements of each of the spaces being conditioned. The systems in general use are as follows:

- Zone control system;

- Double duct system;

- Reheat system.

Zone control system

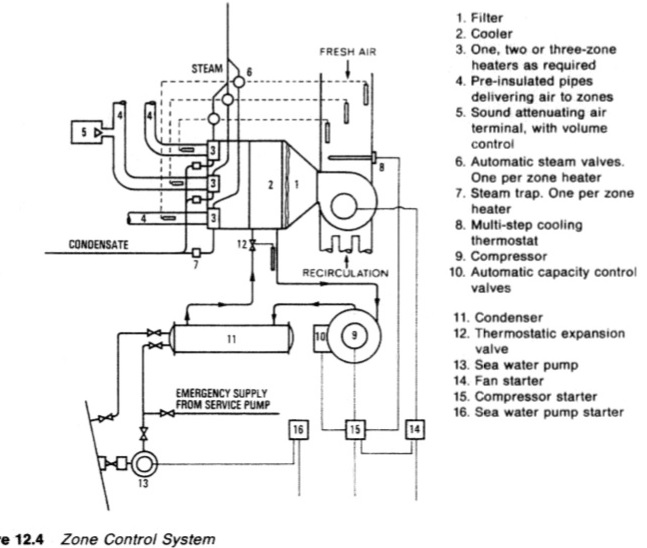

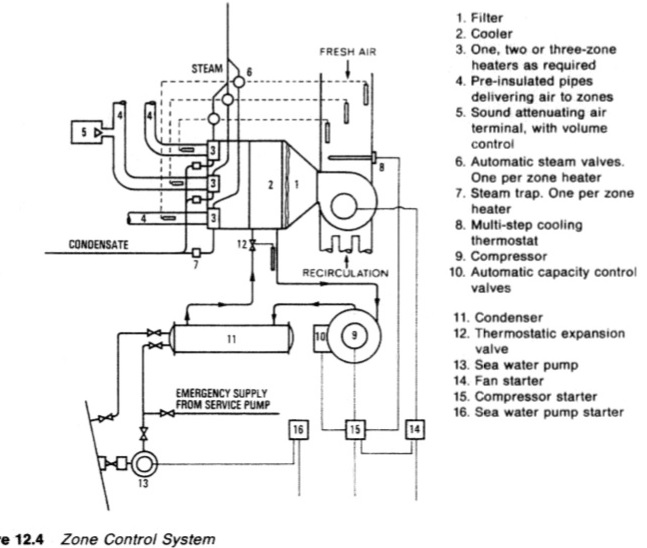

This is the most popular because of its basic simplicity. The accommodation is divided into zones, having different heating requirements. Separate air heaters for each zone are provided at the central unit as shown in Figure 12.4.

Figure 12.4 Zone Control System

The main problem is to obtain a typical sample of air for therrnostatic control of the heaters, for it may not be possible to choose a location which is uninfluenced by local factors. This has led to the general adoption of a compromise solution, which is to vary the temperature of the air leaving the heater in accordance with the outside temperature prevailing. This can be effectively performed by a self-actuating regulator controlled by two thermostat sensors, one in the air leaving the heater, the other outside. Air quantity control in each room served gives individual refinement.

In summer, air temperature is controlled by a multi-step thermostat in the recirculating air stream, which governs the automatic capacity control of the refrigerating plant.

The regulation of temperature by individual air quantity control in this system can give rise to difficulties unless special arrangements are made. For instance, a concerted move to reduce the air volume in a number of cabins would cause increased air pressure in the ducts, with a consequent increase in air flow and possibly in noise level at other outlets. This can be avoided but economic factors usually place a limit on this.

Some degree of control is possible through maintaining a constant pressure at the central unit, but since most of the variation in pressure drop takes place in the ducts, the effect is very limited. A pressure-sensing device some way along each branch duct, controlling a valve at the entry to the branch, strikes a reasonable mean, and is fairly widely applied.

Double duct system

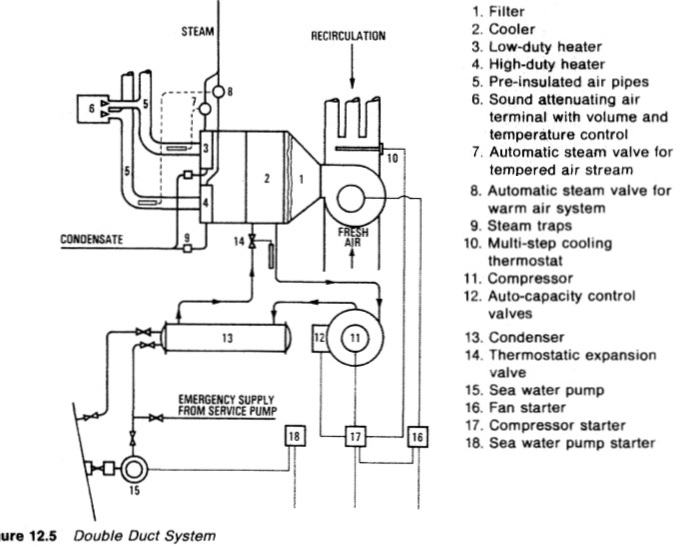

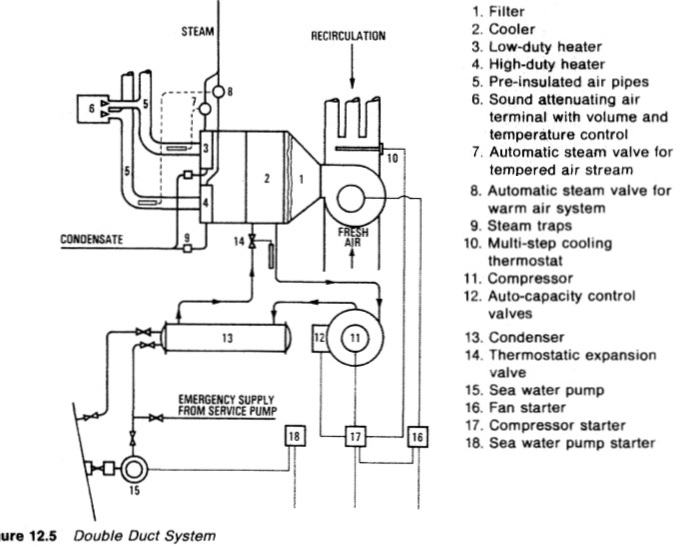

In this system, two separate ducts are run from the central unit to each of the air terminals, as shown in Figure 12.5. In winter two warm air streams, of differing temperatures, are carried to the air terminals, for individual mixing. The temperatures of both air streams are automatically controlled.

In summer the air temperature leaving the cooler is controlled by a multi-step thermostat in the recirculating air stream, which governs the automatic capacity control of the refrigerating plant, as with zone control. Steam is supplied to one of the heaters, so that two air streams are available at the air terminals for individual mixing,

Figure : Marine air conditioning :double duct system

Reheat system

In winter, the air is preheated at the central unit, its temperature being automatically controlled. The air terminals are equipped with electric or hot water heating elements, as shown in Figure 12.6. These raise the temperature of the air to meet the demands of the room thermostats which are individually set.

In the case of electric reheat, fire protection is provided by overheat thermostats which shut down the heaters in the event of air starvation, while a fan failure automatically cuts off the power supply. In summer, the air temperature is controlled by a multi-step thermostat in the recirculating air stream, which governs the automatic capacity control of the refrigerating plant, as in the other system.

Figure : Marine air conditioning reheat system

Precautions against legionella bacteria

A type of pneumonia which may be fatal to older people, has been blamed on the presence of a bacteria associated with the air conditioning plant of large buildings. Because the outbreak which heralded the disease, occurred at a convention for American ex-servicemen (The American Legion), the identified cause of the problem, was labelled legionella bacteria and the sickness is referred to as legionnaires disease.

There is a risk that the bacteria could flourish in the air conditioning systems of ships and consequently a Department of Transport M Notice (1) has been issued to give warning and to recommend preventative measures. The M notice explains that the organisms breed in stagnant water or in wet deposits of slime or sludge. Possible locations for bacteria colonies, are mentioned as being at the air inlet area and below the cooler (stagnant water), in the filter, in humidifiers of the water spray type and in damaged insulation. Provision of adequate drainage is recommended to remove stagnant water.

Guidance is given for regular inspections and cleaning as necessary of filters and other parts, using a 50 ppm super-chlorinated solution as the sterilizing agent. The solution is to be used also on the cooler drain area at not more than three month intervals. Regular sterilization is necessary for water spray type humidifiers (steam humidifiers being preferred).

Summarized below some of the basic procedure of marine air conditioning system :

- Types of air conditioning system

Air conditioning systems may be divided into two main classes — the central unit type in which the air is distributed to a group of spaces through ducting, and the self-contained type, installed in the space it is to serve. .....

- Marine air conditioner

A very significant factor affecting an air conditioning system is the rapidly changing climatic conditions. The equipment has to perform within these variations and has to meet the differing requirements of the occupied spaces of the ship......

- Air conditioning central unit

The elements of a central unit are fan, filter, cooler, heaters and plenum chamber. Normally these are all housed within a single casing, with the possible exception of the fan. It is possible to carry this further by including the refrigerating plant in a single assembly thus providing a complete package. ....

- Air conditioning air terminals

The best designed air conditioning system is only as good as the means of delivering the air to the spaces. The main function of the air terminal is to distribute the air uniformly throughout the spaces without draughts......

- Heating and cooling loads and air quantities

Outside air must be introduced to all living spaces, although the amount of fresh air necessary to sustain life is very small indeed. Space conditions can vary greatly in a short time. They are governed by factors such as body odours and smoking, which may require a fresh air supply of 12 litre/s per person or more. ...

- Air conditioning unit typical specification

To prevent excessive leakage of conditioned air, all doors leading from the conditioned spaces to the outside atmosphere, machinery casing, etc., should be of the self-closing type and reasonably airtight......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||