Home page||Deck machinery||

Handling deck machinery- Anchor windlasses,Anchor capstan & mooring winches

Anchor handling:

The efficient working of the anchor windlass is essential to the safety of the

ship. An anchor windlass can expect to fulfil the following:

1. The windlass cablelifter brakes must be able to control the running anchor

and cable when the cablelifter is disconnected from the gearing when

letting go'. Average cable speeds vary between 5 and 7 m/s during this

operation.

2. The windlass must be able to heave a certain weight of cable at a specified

speed. This full load duty of the windlass varies and may be as high as

70 tonne; figures between 20 and 40 tonne are not unusual. Commonly the

load is between 4 and 6 times the weight of one anchor. The speed of haul

is at least 9m/min and up to 15 m/min.

3. The braking effort obtained at the cable lifter must be at least equal to 40%

of the breaking strength of the cable.

Most anchor handling equipment incorporates warpends for mooring

purposes and light line speeds of up to 0.75 to 1.0 m/s are required. The

conventional types of equipment in use are as follows.

Mooring windlasses

This equipment is self contained and normally one electric or hydraulic motor

drives two cablelifters and two warpends. The latter may not be declutchable

and so will rotate when the cablelifters are engaged. There is some variation

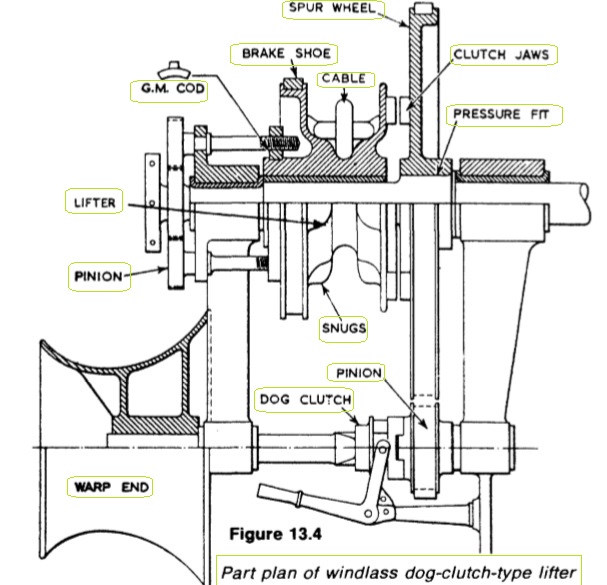

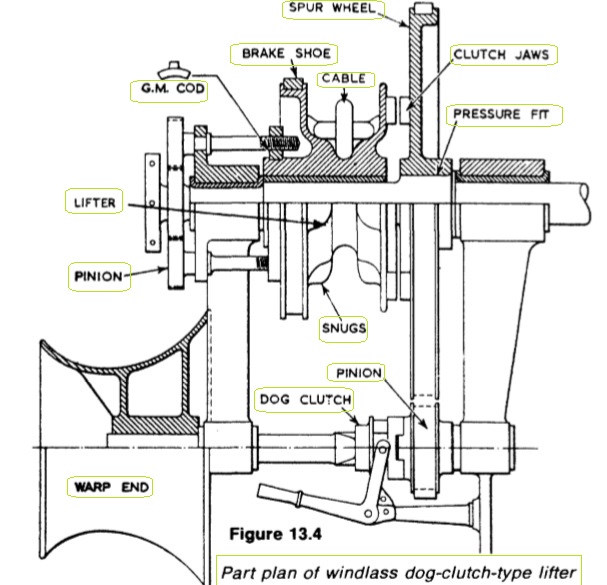

in the detailed design of cablelifters and in their drives. Figure 13.4 shows a

typical arrangement.

Figure : Part plan of windlass dog clutch type lifter

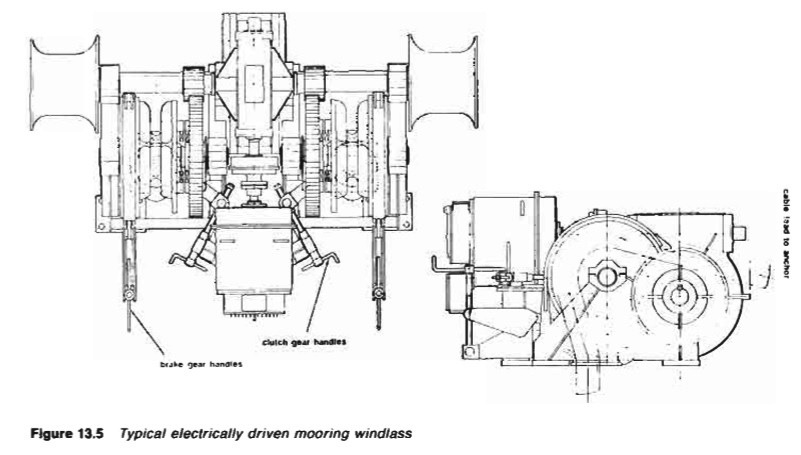

Due to the low speed of rotation required of the

cablelifter whilst heaving anchor (3—5 rev/min) a high gear reduction is

needed when the windlass is driven by a high-speed electric or hydraulic

motor. This is generally obtained by using a high ratio worm gear followed

by a single step of spur gears between the warpend shaft and cablelifters,

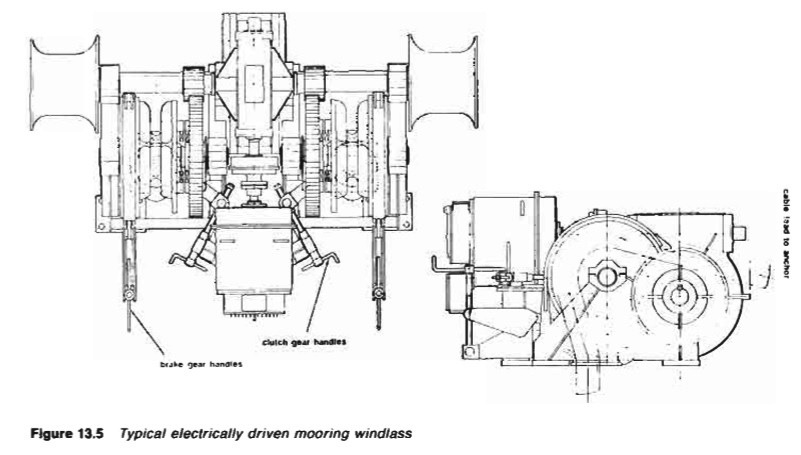

typically as shown in Figure 13.5. Alternatively, multi-steps of spur gear are

used.

Figure : Typical electrically driven mooring windlass

Anchor capstans

With this type of equipment the driving machinery is situated below the deck

and the cablelifters are mounted horizontally, being driven by vertical shafts as

shown in Figure 13.6. In this example a capstan barrel is shown mounted above

the cablelifter (not shown) although with larger equipment (above 76 mm dia.

cable) it is usual to have only the cablelifter, the capstan barrel being mounted

on a separate shaft.

Figure : Anchor cable and warping capstan

Winch windlasses

This arrangement utilizes a forward mooring winch to drive a windlass unit

thus reducing the number of prime movers required. The port and starboard

units are normally interconnected, both mechanically and for power, in order

to provide a stand-by drive and to utilize the power of both winches on the

windlass should this be required.

Control of windlasses

As windlasses are required for intermittent duty only, gearing is designed with

an adequate margin on strength rather than on wear.

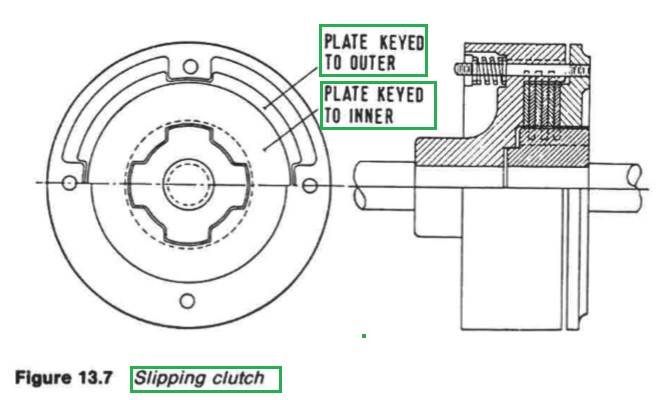

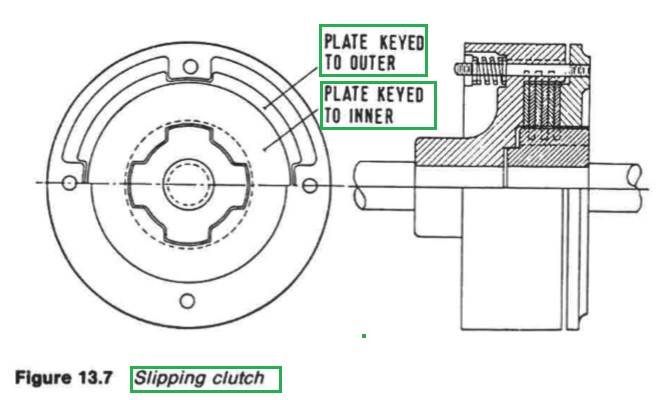

Slipping clutches (Figure 13.7) may be fitted between the drive motors and

the gearing to avoid the transmission of inertia in the event of shock loading on

the cable when, for example, the anchor is being housed.

Figure : Slipping clutch

Windlasses are normally controlled from a local position, the operator

manually applying the cablelifter brake as required to control the speed of the

running cable, and whilst heaving anchor the operator is positioned at the

windlass or at the shipside so that he can see the anchor for housing purposes.

It is quite feasible, however, to control all the functions of the windlass from a

remote position. The spring applied cablelifter brakes are hydraulically

released, and to aid the operator the running cable speed and the length paid

out are indicated at the remote position during letting go. The cablelifter can

also be engaged from the remote position so that the anchor can be veered out

to the waterline before letting go or heaved in as required.

The windlass is in the most vulnerable position so far as exposure to the

elements is concerned and maintenance demands should be an absolute

minimum. Normally primary gearing is enclosed and splash lubricated,

maintenance being limited to pressure grease points for gunmetal sleeve

bearings. However, due to the large size of the final of the bevel or spur

reduction gears, and the clutching arrangements required, these gears are often

of the open type and are lubricated with open gear compounds.

Summarized below some of the basic operation of deck machinery and maintenance guide :

- Powering deck machinery -Systems and components

Pump and motor systems are used for powering deck machinery such as

winches and windlasses. Pump and actuating cylinders are normally employed

for hatch covers. One or more pumps will be used to supply the volume of fluid

at the pressure required to operate one or more motors.

......

- Mooring equipment for general cargo vessel

The operation of mooring a vessel has traditionally required the attendance of

a large number of deck crew fore and aft. Supervision of the moorings was also

necessary to maintain correct tension through changes due to the tides and the

loading or unloading of cargo.

......

- Hydraulic systems for deck machinery and cargo equipment

The three essential components for a hydraulic circuit, are the hydraulic fluid

held in a reservoir tank, a pump to force the liquid through the system and a

motor or cylinder actuator to convert the energy of the moving liquid into a

working rotary or linear mechanical force. Valves to control liquid flow and

pressure are required by some systems.

......

- General cargo ship deck machinery electric drives

Electric motors on vulnerable deck areas may be protected against ingress of

water by being totally enclosed in a watertight casing. Vents are provided on

some winches, which must be opened when the motor is operating in port.

......

- Handling deck machinery- Anchor windlasses,Anchor capstan & mooring winches

The windlass cablelifter brakes must be able to control the running anchor

and cable when the cablelifter is disconnected from the gearing when

letting go'. Average cable speeds vary between 5 and 7 m/s during this

operation.

......

- General cargo ship deck deck crane

A large number of ships are fitted with deck cranes. These require less time to

prepare for working cargo than derricks and have the advantage of being able

to accurately place (or spot) cargo in the hold. On container ships using ports

without special container handling facilities, cranes with special container

handling gear are essential.

......

- Mechanically operated steel hatch covers

Hatch cover equipment like the other deck machinery, has to exist in a very

hostile environment and the importance of regular maintenance cannot be

over-emphasized. Drive boxes and electrical enclosures should be checked

regularly for water-tightness.

......

- Derricks and cargo winches -Ship cargo handling gears

The duty of a deck winch is to lift and lower a load by means of a fixed rope on

a barrel, or by means of whipping the load on the warp ends, to top or luff the

derricks, and to warp the ship.

......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||