Home page||Deck machinery||

Powering deck machinery -

Systems and components

Pump and motor systems are used for powering deck machinery such as

winches and windlasses. Pump and actuating cylinders are normally employed

for hatch covers. One or more pumps will be used to supply the volume of fluid

at the pressure required to operate one or more motors. Pumps may be

classified into two groups:

1. those with a fixed delivery when running at a given speed;

2. those with a variable delivery at a given speed.

Fixed delivery pumps can have their constant output bypassed via control

valves until required or output can be matched to requirements by

incorporating a relief/accumulator, then stopping and starting, varying speed,

or connecting a variable delivery pump in parallel.

Variable delivery pump output can be controlled to give full flow in either

direction, and volume output can be varied from maximum down to zero.

Fixed delivery pumps

Constant output pumps of the gear or lobe type are precision

made to provide high pressure with minimum back leakage. The former

operate on the principle that as gears revolve, fluid is carried around the outside

between the gear teeth and the housing from the suction to the discharge side

of the pump.

Fluid from the discharge side is prevented from returning to the

intake side by the close meshing of the two gears and the small clearances

between the gears and housing. At the discharge side the fluid is discharged

partly by centrifugal effect and partly by being forced from between the teeth

as they mesh.

Gear pumps may be of the conventional kind or of the type with meshing

internal and external gears. Lobe pumps are a variation of

the latter.

Axial cylinder pumps can be made to deliver a fixed output by setting the

swash plate for continuous full stroke operation.

Variable delivery pumps

Variable delivery pumps are used in hydraulic installations as the means of

regulating pump output to suit demand. Steering gears are controlled directly

by varying the pump output and swash plate pumps are used to supply a range

of hydraulic deck machinery. Automatic stroke control can be used to adjust

the output.

Constant delivery pump systems

Hydraulic steering gears which are fitted with constant volume or fixed output

pumps may have a simple control valve arrangement which either delivers full

pump output to the steering gear or bypasses pump output completely.

System pressure rises sharply when oil is channelled to the gear. The fixed

output pumps of Woodward type hydraulic engine governors, supply to

accumulators, which maintain system pressure and hold a reserve of

operational oil against demand which may temporarily exceed pump capacity.

For general hydraulic systems where the pump delivers a constant volume

of oil, speed control of the hydraulic motor can be obtained by delivering the

required amount of oil to the motor through a control valve and diverting the

remainder through a bypass to the pump suction. The pump discharge pressure

is determined by the load. Speed and direction of rotation are controlled by a

lever operated balanced spool valve.

Unit type of circuit

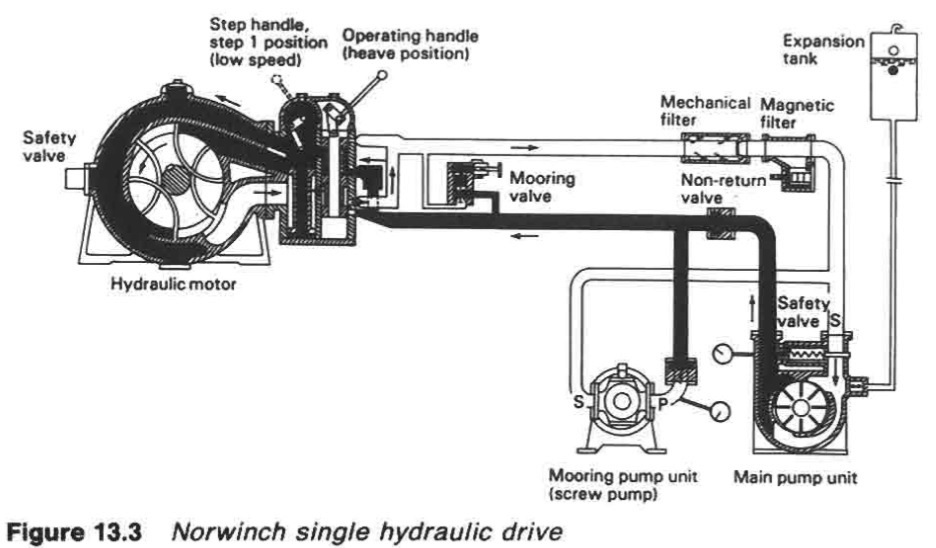

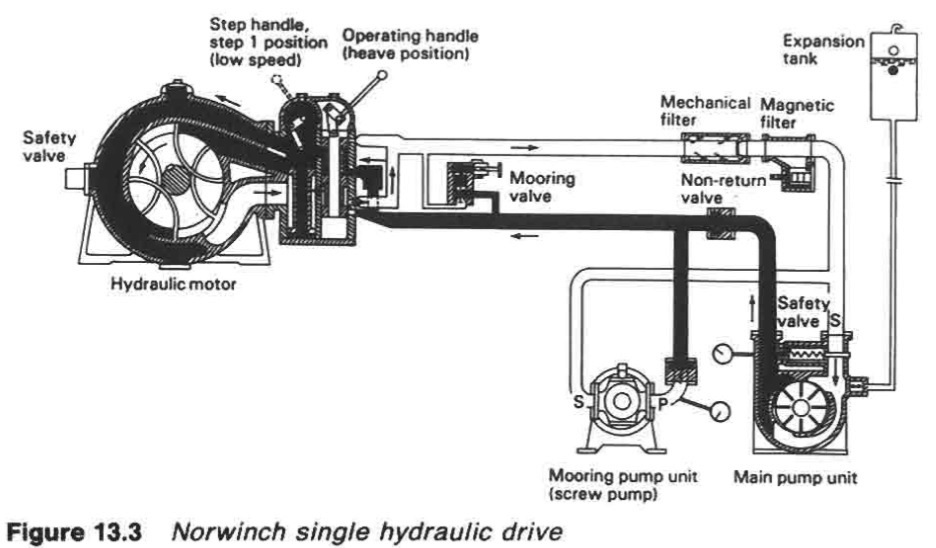

The basic components of a hydraulic system of the Norwinch design are shown

in Figure 13.3. The pump in this case is of the vane type which consists of a

slightly elliptical case with a cylindrical rotor. The latter has radial slots

containing closely fitting rectangular vanes which are forced out against the

casing by centrifugal effect and oil pressure. As the rotor turns, the expanding

and contracting clearance between it and the casing produces a pumping

action. Both mechanical and magnetic filters and a relief valve are provided.

The expansion tank contains a reserve of oil.

Figure : Norwinch single hydraulic drive

The hydraulic motor is also of the

vane type, with vanes mounted in a cylindrical rotor working in a housing

which incorporates two pressure chambers. When the motor is required to

exert maximum torque, oil flow from the pump is directed into both chambers.

For lighter loads an operating lever is actuated to direct the full flow to only

one of the pressure chambers. This system provides two variable speed ranges.

The system shown is for mooring winches which are self-tensioning.

Pumps for hydraulic installations, such as the one described, run at constant

speed and are driven by an electric motor or directly by a prime mover. With

the pump running there is a continuous flow of oil through the system whether

the motor is in operation or not. When the winch is not in use the oil merely

passes through the operating valve, bypassing the hydromotor and returns to

the pump.

Oil pressure is negligible when the hydromotor is idle, reducing power

required to a minimum. Oil in the pipelines to and from the motor always flows

in the same direction. At the motor controls the flow direction can be reversed

to change the rotation of the winch.

Many of the hydraulic systems, fitted to deck machinery are of the 'unit'

type, with one pump driving one motor, but there are great advantages to be

gained by the use of a ring main system. With the latter type of system, one

centrally located hydraulic pump is able to cater for the needs of a number of

auxiliaries which can work simultaneously or alternately at varying loads. As

the equipment powered from this central pumping installation need not be

restricted to deck machinery or to one type of equipment, the system offers

considerable savings on capital cost.

Variable displacement pump systems

The hydraulically operated steering gear with an axial piston (vsg type) or

radial piston (Hele-Shaw type) variable delivery pump, is an example of

variable displacement pump system. The pump itself controls the liquid flow to

move a ram or vane steering gear, so that operational control valves are not

required. The variable delivery pump is driven at constant speed by an a.c.

induction motor; the pump and motor being referred to in the regulations as a

power unit.

The rate of oil flow from the power unit controls the speed of

movement of the steering gear and rudder. A small movement of the telemotor

linkage puts the pump on part stroke and the gear moves through a small

distance, slowly. When a large movement of the rudder is required, the

telemotor linkage puts the pump on full stroke and initially the gear moves

rapidly to take the rudder to the desired angle. As the rudder moves, the

hunting gear gradually brings the pump control towards neutral, lessening the

pump stroke, so that the rate of movement reduces.

A variable displacement system can be used for deck machinery such as

windlasses, winches and capstans and also for cargo pumps. The power unit for

such circuit may be an axial piston (vsg type) pump with swash plate control to

maintain constant pressure in the system. To match the demand of the

hydraulic motors being supplied the swash plate control servo-motor monitors

system pressure and automatically adjusts pump output to keep pressure

constant. Oil cooling is provided by conventional sea-water circulated, tube

type heat exchangers.

System design

Careful system design and contamination control are required during

manufacture and installation of equipment. The number of joints and pipes are

kept to a minimum to reduce the possibility of leakage. Materials are selected

that will produce the least quantity of contaminating particles in the system.

Filters capable of taking out particles down to a specified size are necessary.

Shaft glands or seals must prevent leakage of oil from the machinery and they

must also keep contamination out whether the plant is running or shut down.

It is important with all hydraulic systems to ensure that interlocking

arrangements provided for pump or motor control levers are in the neutral

position before the pump driving motor can be started, in order to avoid

inadvertent running of unmanned machinery. Overload protection on

hydraulic systems is provided by use of the pressure relief valves set between

30-50% in excess of rated full load pressures.

Summarized below some of the basic operation of deck machinery and maintenance guide :

- Powering deck machinery -Systems and components

Pump and motor systems are used for powering deck machinery such as

winches and windlasses. Pump and actuating cylinders are normally employed

for hatch covers. One or more pumps will be used to supply the volume of fluid

at the pressure required to operate one or more motors.

......

- Mooring equipment for general cargo vessel

The operation of mooring a vessel has traditionally required the attendance of

a large number of deck crew fore and aft. Supervision of the moorings was also

necessary to maintain correct tension through changes due to the tides and the

loading or unloading of cargo.

......

- Hydraulic systems for deck machinery and cargo equipment

The three essential components for a hydraulic circuit, are the hydraulic fluid

held in a reservoir tank, a pump to force the liquid through the system and a

motor or cylinder actuator to convert the energy of the moving liquid into a

working rotary or linear mechanical force. Valves to control liquid flow and

pressure are required by some systems.

......

- General cargo ship deck machinery electric drives

Electric motors on vulnerable deck areas may be protected against ingress of

water by being totally enclosed in a watertight casing. Vents are provided on

some winches, which must be opened when the motor is operating in port.

......

- Handling deck machinery- Anchor windlasses,Anchor capstan & mooring winches

The windlass cablelifter brakes must be able to control the running anchor

and cable when the cablelifter is disconnected from the gearing when

letting go'. Average cable speeds vary between 5 and 7 m/s during this

operation.

......

- General cargo ship deck deck crane

A large number of ships are fitted with deck cranes. These require less time to

prepare for working cargo than derricks and have the advantage of being able

to accurately place (or spot) cargo in the hold. On container ships using ports

without special container handling facilities, cranes with special container

handling gear are essential.

......

- Mechanically operated steel hatch covers

Hatch cover equipment like the other deck machinery, has to exist in a very

hostile environment and the importance of regular maintenance cannot be

over-emphasized. Drive boxes and electrical enclosures should be checked

regularly for water-tightness.

......

- Derricks and cargo winches -Ship cargo handling gears

The duty of a deck winch is to lift and lower a load by means of a fixed rope on

a barrel, or by means of whipping the load on the warp ends, to top or luff the

derricks, and to warp the ship.

......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||