Home page||Deck machinery||

General cargo ship deck machinery electric drives

Electric motors on vulnerable deck areas may be protected against ingress of

water by being totally enclosed in a watertight casing. Vents are provided on

some winches, which must be opened when the motor is operating in port.

The direct current (d.c.) motor, although it is relatively costly and requires

regular brush gear maintenance, is still used for deck machinery because it has a

full speed range with good torque at any speed. The control of d.c. motors by

contactor-switched armature resistances, common in the days when ships'

electrical supplies were d.c., has long been replaced by a variety of

Ward-Leonard type systems which give a better, more positive regulation

particularly for controlled lowering of loads. The Ward-Leonard generator is

normally driven by an a.c. motor.

An important feature of the d.c. drive is its efficiency, particularly in

comparison with a.c. drives, when operating at speeds in the lower portion of

the working range. The d.c. motor is the only electric drive at present in

production which can be designed to operate in a stalled condition

continuously against its full rate torque and this feature is used for automatic

mooring winches of the 'live motor' type. The majority of d.c. winch motors

develop full output at speeds of the order of 500 rev/min and where necessary

are arranged to run up to two to four times this speed for light line duties.

Windlass motors on the other hand do not normally operate with a run up in

excess of 2 : 1 and usually have a full load working speed of the order of

1000 rev/min.

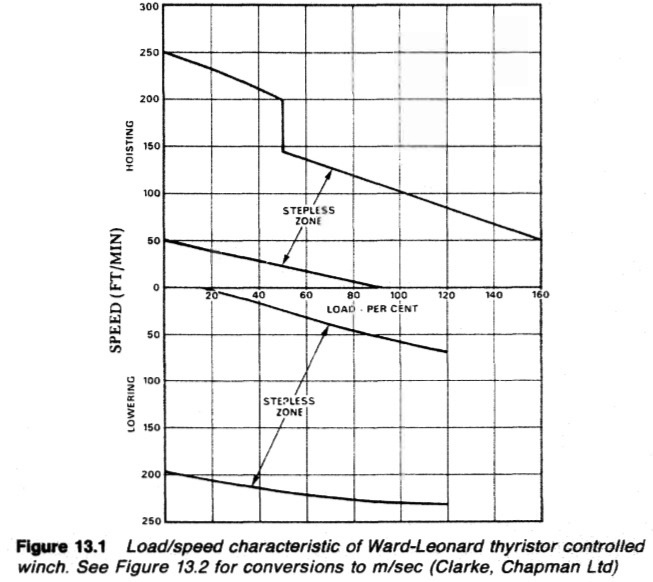

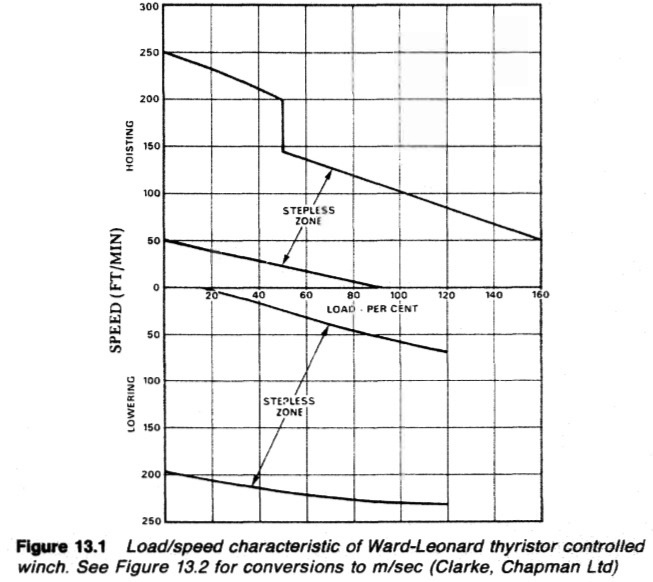

Direct current motors may also be controlled by static thyristor converters

which convert the a.c. supply into a variable d.c. voltage of the required

magnitude for any required armature speed. These converters must be of a type

capable of controlled rectification and inversion with bi-directional current

flow if full control is to be obtained (Figure 13.1).

Figure 13.1 Load/speed characteristic of Ward-Leonard thyhstor controlled winch. See Figure 13.2 for conversions to m/sec (Clarke, Chapman Ltd)

Alternating current induction motors, of either the wound rotor or of the

cage type are also in common use. With these the speed may be changed by

means of pole changing connections and in the case of the wound rotor

induction motor, also by changing the value of the outside resistance

connected in the rotor circuit. The pole change method involves the switching

of high currents at medium voltage in several lines simultaneously, requiring

the use of multi-pole contactors.

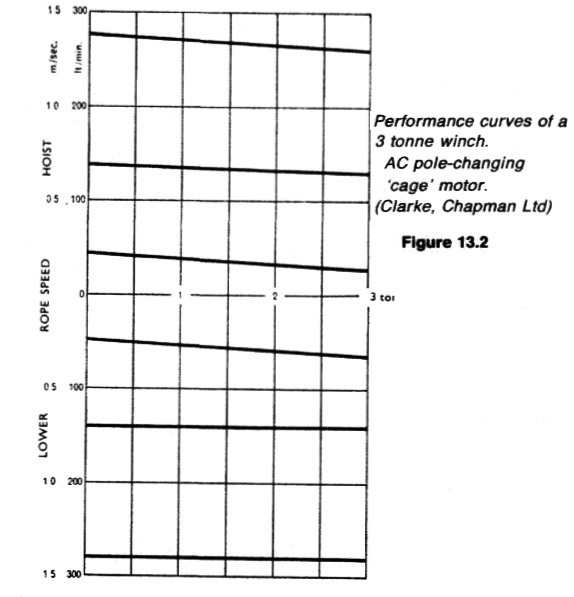

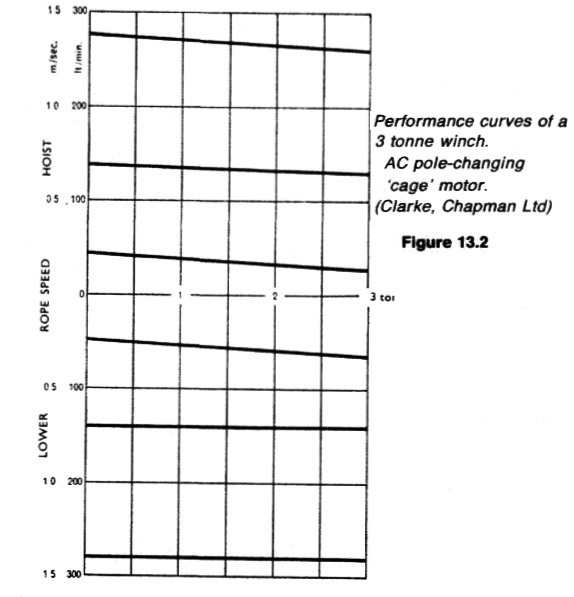

The pole change speed control method offers

a choice of perhaps three discrete speeds such as 0.65, 0.325 and 0.1025 m/s

corresponding to 4, 8 and 24 pole operation. The wound rotor motor is flexible

when hoisting a load, because the starting resistances can be reintroduced into

the rotor circuit and the load will cause the motor to slip.

The slip gives a range

between the speeds dictated by the pole arrangement. As with resistance

controlled d.c. motors, difficulty is experienced when providing speed control

of an overhauling load, i.e. lowering a suspended load. The disadvantages must

be balanced against lower cost, particularly of the cage type induction motor,

in comparison with the more flexible d.c. motor. Typical performance curves

are shown in Figure 13.2.

Figure : Performance curves of a 3 tonne winch. AC pole-changing'cage' motor. (Clarke, Chapman Ltd)

Another form of induction motor control system is based on the relationship

between output torque and applied voltage, the torque being proportional to

the voltage squared. The controller takes the form of a three-phase series

regulator with an arm in each supply line to the motor.

A stable drive system

can only be achieved by this means if a closed loop servo control system is used

in conjunction with a very fast acting regulator which automatically adjusts the

output torque to suit the load demand at the set speed. Control of an

overhauling load is made possible by using injection braking techniques. A

combined system employing both these control principles can provide full

control requirements for all deck machinery.

The a.c. drives described operate at the supply frequency and consequently

rapid heating of the motor will occur if the drive is stalled when energized.

The majority of a.c. motors on deck machinery run at a maximum speed

corresponding to the 4 pole synchronous speed of 1800 rev/min on a 60 Hz

supply.

These speeds are similar to the maximum speeds used with d.c. drives

and the bearings and shaft details tend to be much the same. The motor

bearings are normally grease lubricated. However, where the motor is flange

mounted on an oil bath gearcase, the driving end bearing is open to the

gearcase oil and grease lubrication is not required.

Summarized below some of the basic operation of deck machinery and maintenance guide :

- Powering deck machinery -Systems and components

Pump and motor systems are used for powering deck machinery such as

winches and windlasses. Pump and actuating cylinders are normally employed

for hatch covers. One or more pumps will be used to supply the volume of fluid

at the pressure required to operate one or more motors.

......

- Mooring equipment for general cargo vessel

The operation of mooring a vessel has traditionally required the attendance of

a large number of deck crew fore and aft. Supervision of the moorings was also

necessary to maintain correct tension through changes due to the tides and the

loading or unloading of cargo.

......

- Hydraulic systems for deck machinery and cargo equipment

The three essential components for a hydraulic circuit, are the hydraulic fluid

held in a reservoir tank, a pump to force the liquid through the system and a

motor or cylinder actuator to convert the energy of the moving liquid into a

working rotary or linear mechanical force. Valves to control liquid flow and

pressure are required by some systems.

......

- General cargo ship deck machinery electric drives

Electric motors on vulnerable deck areas may be protected against ingress of

water by being totally enclosed in a watertight casing. Vents are provided on

some winches, which must be opened when the motor is operating in port.

......

- Handling deck machinery- Anchor windlasses,Anchor capstan & mooring winches

The windlass cablelifter brakes must be able to control the running anchor

and cable when the cablelifter is disconnected from the gearing when

letting go'. Average cable speeds vary between 5 and 7 m/s during this

operation.

......

- General cargo ship deck deck crane

A large number of ships are fitted with deck cranes. These require less time to

prepare for working cargo than derricks and have the advantage of being able

to accurately place (or spot) cargo in the hold. On container ships using ports

without special container handling facilities, cranes with special container

handling gear are essential.

......

- Mechanically operated steel hatch covers

Hatch cover equipment like the other deck machinery, has to exist in a very

hostile environment and the importance of regular maintenance cannot be

over-emphasized. Drive boxes and electrical enclosures should be checked

regularly for water-tightness.

......

- Derricks and cargo winches -Ship cargo handling gears

The duty of a deck winch is to lift and lower a load by means of a fixed rope on

a barrel, or by means of whipping the load on the warp ends, to top or luff the

derricks, and to warp the ship.

......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||