Home page||Ship employment

||

Trim and stability booklet for cargo ships - how to use them

Commercial ships usually have a trim and stability booklet which may contain either curves of form or

hydrostatic tables and stability and trim characteristics for various conditions of loading. A typical trim and stability booklet will contain the following data:

i) Vessel characteristics,

including principal dimensions,

tonnage, location of

draft marks, builder, official

and registry numbers, etc.

ii) Instructions for use of the

nomograms, curves, and other

data in the booklet to calculate

stability and trim of the vessel

for given loading conditions.

iii) General operating instructions

and precautions.

iv) Tabulated tank and hold

capacities.

v) Hydrostatic properties (KM,

LCB, LCF, etc.) tabulated or

plotted as a function of mean

draft.

vi) Metacentric Height (GM) diagram, showing GM for tabulated conditions of loading and minimum required GM for vessel service.

vii) Trim diagram to calculate vessel trim when weights are added at locations other than the vessel center of gravity.

viii) Weight distribution and stability information for various conditions of loading.

ix) Liquid loading diagram, showing the location, capacity, and effect on list and trim of the ship’s tanks.

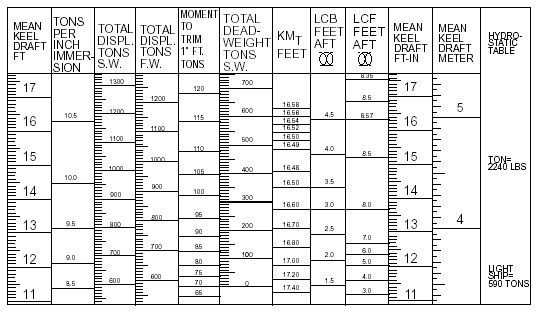

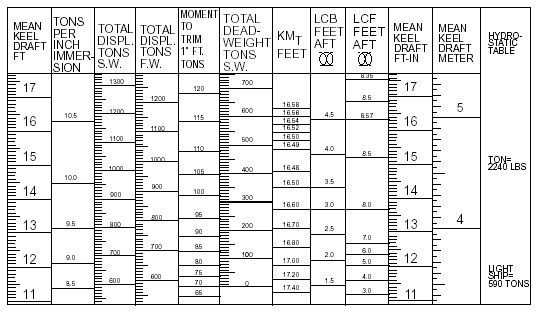

Figure shows a

typical hydrostatic table.

Related info:

Docking Plans , Reports & other structural plans for cargo ships

Other useful articles :

- Assigning loadlines marks

Loadlines are marks punched into and painted on the sides of general cargo ships.The assigning of the vessels loadline and the issue of the Certificate is the

responsibility of the Marine Authority of the country. .

More .....

-

Cargo ships Loaded Condition

closely monitor the ship's condition during cargo

operations to ensure that if a significant deviation from the agreed loading/unloading

plan is detected all cargo and ballast operations must STOP..

More .....

-

Packing a container recommended method

Packing a container should always be done on level plane either on the ground,on a railcar, or on a trailer. In the case of a trailer, care should be taken to ensure the trailer cannot tip whilst being packed especially if a forklift truck is being used. If necessary the trailer should be propped. Brakes should be securely applied and wheels choked.

More .....

- Packing principles relating to cargo in containers

Where relevant, stowing should be carried out in a sequence which will permit

rapid checking and storage operations during and after unloading. Should the

consignment include cargo subject to customs pre-entry procedures, customs

examination would be made easier and unloading avoided if the cargo were

stowed at the end of the container by the door.

More .....

- Container Securing guidance

Containers have very little strength in any direction other than vertically

through the corner posts thus it is necessary to provide substantial support

to the containers when they are on the ship. Stowage of containers is with

their longer dimension fore and aft since the ship motion transmitted to

cargo is greater in rolling than pitching and it is therefore prudent to limit

any possible cargo movement within the container to the shorter transverse

dimension.

More .....

- Trim and stability booklet for cargo ships

Contain either curves of form or hydrostatic tables and stability and trim characteristics for various conditions of loading

.

More .....

- Broken stowage? Cargo ships guideline

The access shall be separate from the hatchway opening, and shall be by a stairway if possible. A fixed ladder, or a line of fixed rungs, shall have no point where they fill a reverse slope

.

More .....

-

Ship type, design and facilities for cargo

Cargo gear is designed for speed and flexibility for handling breakbulk, palletized, or container cargo. Various combinations of derricks,

winches, and deck cranes are used for the handling of cargo. Cranes are fitted on many vessels to reduce manpower requirements. Some ships

have special heavy-lift derricks that may serve one or more holds. Booms are rigged for either yard and stay (burton) or swinging-boom

operation.

More .....

- Cargo ships structural plans- how to use them

Structural plans, sometimes called scantlings plans, show dimensions of the ships framing and plating. The midships section drawing, generally available for all ships

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||