Home page||Ship employment

||

Modern cargo ships structural plans- how to use them

Ships plan

Structural plans, sometimes called scantlings plans, show dimensions of the ships framing and plating. The midships section drawing, generally available for all ships, and the shell expansion plan are particularly useful. The midships section drawing provides

the data required for the midships section modulus calculation.

The shell expansion plan and larger scale shell plating drawings show details

of the hull plating such as the size, thickness, and material of the plating. They also show details of openings, fittings, and appendages attached

to the plating. Much of the data needed for designing patches and structural repairs, and for determining the feasibility of making hull cuts can

be obtained from shell drawings.

Docking Plans and Reports

In addition to docking information, the ship docking plan shows the underwater profile of the ship, the

plan view of its bottom, and locations of underwater appendages, sea suctions, and overboard discharges, with reference points and measurements

to locate them. The docking plan also provides vertical measurements from the main deck and base line, the location and dimensions of the docking

blocks for the three docking positions, and the critical dimensions of the ship.

Docking reports provide a complete and accurate description of the ship’s bottom. They describe the results of inspections and work done while

the ship is in dry dock. Reports for emergent or unplanned dockings do not provide a complete bottom description, but address only the work

done during the docking; reports of unplanned drydockings can be considered supplements to the report of the previous regular dry docking. Docking

reports are further supplemented by subsequent underwater hull inspection, hull cleaning, and repair or work reports. In addition to an overall

description of the ship’s bottom, docking reports include two items of interest to salvors: the shaft covering, if any, and the type of paint applied

to the ship’s bottom and appendages. Information on paint systems and coverings alerts the diving supervisor to potential toxic hazards.

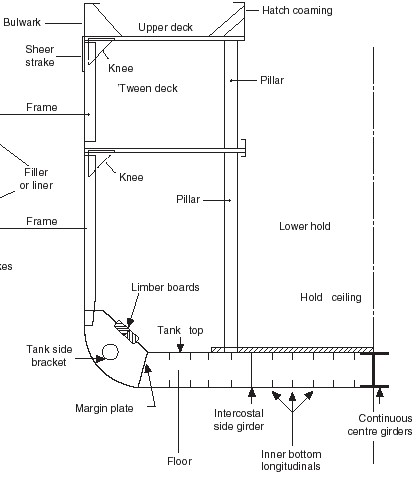

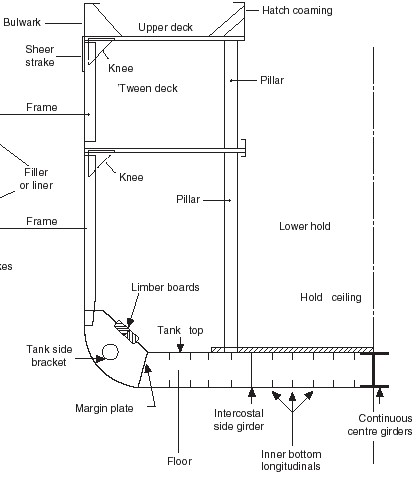

Fig:General cargo ships midship cross section

Capacity Plan

A plan of the spaces available for cargo, fuel, fresh water, water ballast,

etc, and containing cubic or weight capacity lists for such spaces and a scale showing

deadweight capacities at varying draughts and displacements.

It would be difficult and inconvenient to gather all those information and place them on

one plan in a clear and legible manner. In addition, all these pieces of information can

be found on various other drawings. To avoid repeating data and multiplying existing

documents it is recommended to create a Capacity Plan as a set of documents listed below:

1. General Part

2. Coordinate System

3. Draught Marks

4. Load Line Mark and Deadweight Scale

5. Tank Space Information

6. Cargo Space Information

Other useful articles :

- Assigning loadlines marks

Loadlines are marks punched into and painted on the sides of general cargo ships.The assigning of the vessels loadline and the issue of the Certificate is the

responsibility of the Marine Authority of the country. .

More .....

-

Cargo ships Loaded Condition

closely monitor the ship's condition during cargo

operations to ensure that if a significant deviation from the agreed loading/unloading

plan is detected all cargo and ballast operations must STOP..

More .....

-

Packing a container recommended method

Packing a container should always be done on level plane either on the ground,on a railcar, or on a trailer. In the case of a trailer, care should be taken to ensure the trailer cannot tip whilst being packed especially if a forklift truck is being used. If necessary the trailer should be propped. Brakes should be securely applied and wheels choked.

More .....

- Packing principles relating to cargo in containers

Where relevant, stowing should be carried out in a sequence which will permit

rapid checking and storage operations during and after unloading. Should the

consignment include cargo subject to customs pre-entry procedures, customs

examination would be made easier and unloading avoided if the cargo were

stowed at the end of the container by the door.

More .....

- Container Securing guidance

Containers have very little strength in any direction other than vertically

through the corner posts thus it is necessary to provide substantial support

to the containers when they are on the ship. Stowage of containers is with

their longer dimension fore and aft since the ship motion transmitted to

cargo is greater in rolling than pitching and it is therefore prudent to limit

any possible cargo movement within the container to the shorter transverse

dimension.

More .....

- Trim and stability booklet for cargo ships

Contain either curves of form or hydrostatic tables and stability and trim characteristics for various conditions of loading

.

More .....

- Broken stowage? Cargo ships guideline

The access shall be separate from the hatchway opening, and shall be by a stairway if possible. A fixed ladder, or a line of fixed rungs, shall have no point where they fill a reverse slope

.

More .....

-

Ship type, design and facilities for cargo

Cargo gear is designed for speed and flexibility for handling breakbulk, palletized, or container cargo. Various combinations of derricks,

winches, and deck cranes are used for the handling of cargo. Cranes are fitted on many vessels to reduce manpower requirements. Some ships

have special heavy-lift derricks that may serve one or more holds. Booms are rigged for either yard and stay (burton) or swinging-boom

operation.

More .....

- Cargo ships structural plans- how to use them

Structural plans, sometimes called scantlings plans, show dimensions of the ships framing and plating. The midships section drawing, generally available for all ships

More .....

Role of Classification Societies in maintaining cargo ships standard seagoing condition

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||