Home page||Ship employment

||

Deck cranes for efficient cargo handling on board cargo ships

Cargo cranes – Shipboard cranes of various types and capacities are still required for

multi-purpose cargo vessels, geared bulk carriers, feeders, reefers, heavy lift vessels and

some forest product carriers. Manufactures offer crane designs and special handling

attachments (container spreaders, rotators and grabs) to suit all dry cargo trades.

Computer-based cargo spotting systems enable even relatively unskilled operators

to cope with the pendulum effects and centrifugal forces. They also help in keeping

containers or other cargo units constantly aligned with a given axis, regardless of slewing

motion and other external forces. Such electronic aids substantially improve productivity.

Some owners report a doubling of the hourly container-handling rate. Other benefits

include: reduced operator fatigue, improved safety and lower cargo and ship structure

damage.

Cranes have replaced derricks on many modern ships. Generally they are considered as an alternative to the

union purchase rig. Deck cranes have a number of advantages, the rigging

time being negligible, and the crane is able to pick up and land permitted

loads anywhere within its working radius. The safe working loads of cranes

is generally of the order of 10 to 15 tonnes and larger cranes are available

capable of lifts from 30 to 40 tonnes. As with the union purchase rig the

crane is intended for rapid cargo loading and discharging duties with loads

which only occasionally exceed, say, 3 tonnes. There is some controversy

regarding the merits of cranes as opposed to the union purchase rig, but evidence

is available to show that the crane is perhaps less efficient with very

light loads.

Cranes may often be positioned on the ship’s centre line, but this may

require an extremely long jib when the ship’s beam is large and a reasonable

outreach is desired. Transverse positional cranes may then be fitted which,

when not under load, can be moved port or starboard and secured to work

the hatch and give the desired outreach. Alternatively fixed cranes, one at

each end of the hatch, may be placed at opposite corners. This is an

arrangement which is useful in discharging to port and starboard simultaneously.

There is also a crane which is mounted on a hatch cover section

capable of travelling under load along the hatch coaming in the longitudinal

direction.

Deck cranes are available from specialist manufacturers and the shipbuilder

would be responsible for installation, any local strengthening, and

seatings. They are normally positioned

between the holds, often on a platform which can be rotated through

360°, provides an immediately operational unit requiring

only one man to operate it. Double gearing is a feature of most designs,

providing a higher speed at lighter loads. Various types of crane exist

for particular duties, for example a general duties crane using a hook

and a grabbing crane for use with bulk cargoes.

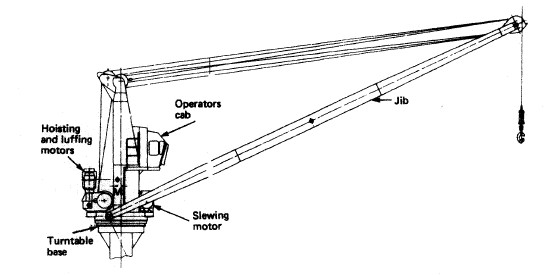

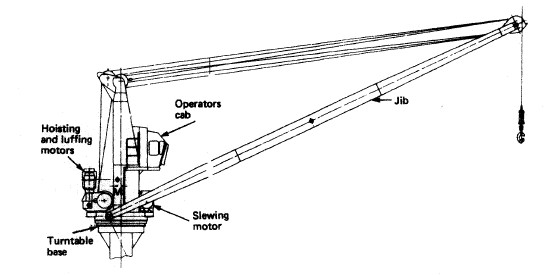

Fig: General Cargo Ships deck crane

Three separate drives

provide the principal movements: a hoisting motor for lifting the load, a

luffing motor for raising or lowering the jib, and a slewing motor for

rotating the crane. The operator's cab is designed to provide clear views

of all the cargo working area so that the crane operator can function

alone. The crane is usually mounted on a pedestal to offer adequate

visibility to the operator. For occasional heavy loads arrangements for

two cranes to work together, i.e. twinning, can be made with a single

operator using a master and slave control system in the two cranes. A

common revolving platform will be necessary for this arrangement. The

operating medium for deck crane motors may be hydraulic or electric,

utilising circuits referred to earlier.

Winches and cranes operation

Winches and cranes fitted for lifting cargo on board is required to be of adequate strength and stability for each load, having regard in particular to the stress induced at its mounting or fixing points , securely anchored, adequately ballasted or counterbalanced and supported by outriggers

as necessary to ensure its stability when lifting.

Fig:General cargo ship BBC-Kusan mounted with deck cranes

The drum end of wire runners or falls should be secured to winch

barrels or crane drums by proper clamps or U-bolts. The runner or fall

should be long enough to leave at least three turns on the barrel or drum

at maximum normal extension. Slack turns of wire or rope on a barrel or

drum should be avoided as they are likely to pull out suddenly under load.

When a winch is changed from single to double gear or vice versa,

any load should first be released and the clutch should be secured so that it

cannot become disengaged when the winch is working.

Steam winches should be so maintained that the operator is not

exposed to the risk of scalding by leaks of hot water and steam.

Before a steam winch is operated, the cylinders and steam pipes

should be cleared of water by opening the appropriate drain cocks. The

stop valve between winch and deck steam line should be kept

unobstructed. Adequate measures should be taken to prevent steam

obscuring the driver's vision in any part of a working area.

Ships' cranes should be properly operated and maintained in

accordance with manufacturers' instructions. Companies, employers and

masters, as appropriate, should ensure that sufficient technical information is

available including the following information:-

(i) Length, size and safe working load of falls and topping lifts.

(ii) Safe working load of all fittings;

(iii) Boom limiting angles;

(iv) Manufacturers' instructions for replacing wires, topping up

hydraulics and other maintenance as appropriate.

Power operated rail mounted cranes should have the following

facilities incorporated in their control systems:-

(a) facilities to prevent unauthorised startup;

(b) an efficient braking mechanism which will arrest the motion along the

rails, and where safety constraints require, emergency facilities operated

by readily accessible controls or automatic systems should be available

for braking or stopping equipment in the event of failure of the main

facility;

(c) guards which reduce as far as possible the risk of the wheels running

over persons' feet, and which will remove loose materials from the rails.

When a travelling crane is moved, any necessary holding bolts or

clamps should be replaced before operations are resumed.

Access to a crane should be always by the proper means provided.

Cranes should be stationary while accessing.

Deck crane maintenance

All deck machinery is exposed to the most severe aspects of the

elements. Total enclosure of all working parts is usual with splash

lubrication for gearing. The various bearings on the shafts will be

greased by pressure grease points. Open gears and clutches are

lubricated with open gear compound. Particular maintenance tasks will

be associated with the type of motor drive employed.

On some vessels, it was reported that the ship's staff had carried out unauthorised repairs to crane jibs by cropping and welding inserts over damaged or wasted sections. Crane jibs are subject to heavy, fluctuating loads and must be periodically inspected, surveyed, load-tested and certified. They are often made of high-tensile, for which special procedures have to be observed during repairs. Therefore, repairs must be carried out only in consultation with the manufacturer and classification society concerned. Any damage noticed to crane jibs must be reported to the ship owner/manager and advice sought before carrying out any kind of repair.

More on general cargo ship :

- Rope handling safe procedure

Ropes are made of short fibres that are spun into yarns,

which are then made into flat or twisted strands.

And the strands are spun or braided to make the finished

rope .

More .....

-

Synthetic man-made ropes and hawsers

Although natural fibre ropes are still widely used throughout the marine industry, they have been superseded by synthetic fibres for a great many

purposes. Not only do the majority of synthetic ropes have greater strength

than their natural fibre counterparts, but they are more easily obtainable

and at present considerably cheaper.

More .....

-

Natural fibre rope

All natural fibre rope is manufactured from manilla, sisal, hemp, coir, cotton

or flax fibres.The process of manufacture consists of twisting the fibres

into yarns and turning the yarns in an opposite direction to establish the

strands.

More .....

-

Lay of Ropes and hawsers - Small Stuff descriptions

The lay of rope is a term used to describe the nature of the twist that produces the complete rope .The most common form of rope at sea is known as ‘hawser laid rope’ comprising three strands laid up right- or lefthanded.

More .....

- Stresses in ship structures and how to mitigate

Heavy weights tend to cause a downward deflection of the deck area supporting the load .This subsequently produces stresses, with

consequent inward and outward deflections of supporting bulkheads,

depending on the position of initial loading .

More .....

- Anchoring safe practice

Prior approaching an area for anchoring ships master should investigate fully a suitable anchoring position and conduct a planned approach including speed reduction in ample time and orienting the ships head prior anchoring to same as similar sized vessels around or stem the tide or wind whichever is stronger . Final decision to be made on method of anchoring to be used , the number of shackles , the depth of water, expected weather and holding ground. .

More .....

- MacGregor single-pull weather-deck hatch cover

Hatch covers are used to close off the hatch opening and make it

watertight. Wooden hatch covers, consisting of beams and boards over

the opening and covered with tarpaulins, were once used but are no

longer fitted. Steel hatch covers, comprising a number of linked steel

covers, are now fitted universally. Various designs exist for particular

applications, but most offer simple and quick opening and closing,

which speed up the cargo handling operation..

More .....

- Cargo holds access arrangement

The access shall be separate from the hatchway opening, and shall be by a stairway if possible. A fixed ladder, or a line of fixed rungs, shall have no point where they fill a reverse slope

.

More .....

- Prepare cargo holds prior loading

Washing is always carried out after the compartment has been swept. Drying time for washed compartments must be allowed for, before loading the next cargo; this time will vary with the climate, but two to three days must be expected.

More .....

- Strength and stability of the Lifting appliances

The vessel's structure, crane, derrick or other lifting device and the supporting structure should be of sufficient strength to withstand the loads

that will be imposed when operating at its maximum load moment .

More .....

- Lifting appliances - Maintenance, testing, controls & safety measures

When there is any suspicion that any appliance or item of

equipment may have been subjected to excessive loads, exceeding the Safe

Working Load (SWL), or subjected to treatment likely to cause damage, it

should be taken out of service until it can be subjected to a thorough

examination by a competent person.

More .....

- Safe operation of Lifting appliances and gears

All lifting operations must be properly planned, appropriately

supervised and carried out to protect the safety of workers.

More .....

- Derricks for lifting cargo on board

Derricks for lifting cargo on board is required to be of adequate strength and stability for each load, having regard in particular to the stress induced at its mounting or fixing points , securely anchored, adequately ballasted or counterbalanced and supported by outriggers

as necessary to ensure its stability when lifting.

More .....

- Deck cranes

Deck cranes have a number of advantages, the rigging

time being negligible, and the crane is able to pick up and land permitted

loads anywhere within its working radius. The safe working loads of cranes

is generally of the order of 10 to 15 tonnes and larger cranes are available

capable of lifts from 30 to 40 tonnes..

More .....

- Characteristics of Marine paints

Paint consists of pigment dispersed in a liquid referred to as the ‘vehicle’.

When spread out thinly the vehicle changes in time to an adherent dry film.

The drying may take place through one of the following processes..

More .....

- Protection by Means of Paints

It is often assumed that all paint coatings prevent attack on the metal

covered simply by excluding the corrosive agency, whether air or water. This

is often the main and sometimes the only form of protection; however there

are many paints which afford protection even though they present a porous

surface or contain various discontinuities. .

More .....

- Role classification societies maintaining seaworthiness of vessels

classification societies publish rules and regulations which are principally concerned with the strength of the ship, the provision of adequate equipment, and the reliability of the machinery .

More .....

- Periodic survey requirement by classification societies

To maintain the assigned class all steel ships are required to be surveyed and examined by the Society’s

surveyors at regular periods.

The major hull items to be examined at these surveys only are discussed

here..

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||