Home page||Ship employment

||

Cargo Ships Lifting appliances - Maintenance, testing, controls & safety measures

Regular Maintenance for Lifting appliances on board

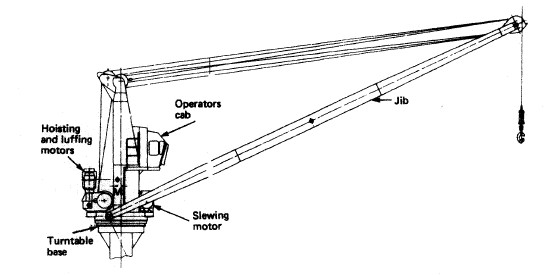

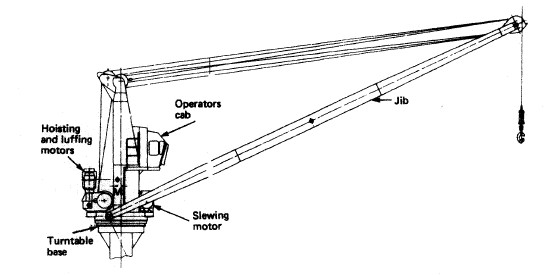

Fig: Cargo Ships deck crane

In order to ensure that all parts of lifting equipment and related

equipment are kept in good repair and working order, regular preventative

maintenance should be carried out. Maintenance should include regular

examinations by a competent person. Such examinations should be carried

out as required by the Regulations but in any event at least once annually.

Checks should look for general material defects such as cracks, distortion,

corrosion and wear and tear that could affect safe working load and overall

strength.

When there is any suspicion that any appliance or item of

equipment may have been subjected to excessive loads, exceeding the Safe

Working Load (SWL), or subjected to treatment likely to cause damage, it

should be taken out of service until it can be subjected to a thorough

examination by a competent person.

Listed below are some suggested maintenance items:-

i) Greasing should be thorough and frequent, as dry bearings impose

additional loads that can lead to failure.

ii) The condition of all ropes and chains should be checked regularly for

wear, damage and corrosion and replaced as necessary.

iii) Shackles, links and rings should be renewed when wear or damage is

evident.

iv) Structures should be examined frequently for corrosion, cracks,

distortion and wear of bearings, securing points etc.

v) Hollow structures such as gantries or masts should be checked for

trapped water inside. If water is found, the structure should be drained,

appropriately treated and then sealed.

vi) Regular function tests of controls, stops, brakes, safety devices for

hoisting gear etc, should be carried out preferably before the start of

operations.

Additional items may be appropriate

dependant upon the equipment fitted to an individual vessel.

Testing of lifting appliances on board

No lifting equipment, accessory for lifting or loose gear is to be

used after manufacture or installation, or after any repair or modification

which is likely to alter the safe working load or affect the strength or

stability of the equipment, without having been first tested by a competent

person.

Upon the completion of any test of lifting equipment, accessory

for lifting or item of loose gear carried out in accordance with , the

equipment, accessory or gear shall be thoroughly examined and certified for

use by the person carrying out the test.

Additionally Ship's lifting equipment is not to be used unless it has been tested

by a competent person within the preceding five years.

Where the safety of lifting equipment depends on the installation

conditions, it should be inspected by a competent person before it is used

for the first time. Such inspections should be undertaken on initial

installation or after re-assembly at another location, to ensure that it has

been installed correctly, in accordance with any manufacturer's instructions,

and is safe for workers to operate as well as being able to function safely.

Any lifting equipment or accessory for lifting which is, or has been,

exposed to conditions which could cause deterioration in its condition

should be:-

(a) thoroughly examined

(i) in the case of lifting equipment for lifting persons or an accessory

for lifting, at least every 6 months;

(ii) in the case of other lifting equipment, at least every 12 months; or

(iii) in either case, in accordance with an examination scheme; and

(iv) whenever exceptional circumstances which are liable to jeopardise

the safety of the lifting equipment have occurred; and

(b) where appropriate, inspected by a competent person at suitable

intervals,

On some vessels, it was reported that the ship's staff had carried out unauthorised repairs to crane jibs by cropping and welding inserts over damaged or wasted sections. Crane jibs are subject to heavy, fluctuating loads and must be periodically inspected, surveyed, load-tested and certified. They are often made of high-tensile, for which special procedures have to be observed during repairs. Therefore, repairs must be carried out only in consultation with the manufacturer and classification society concerned. Any damage noticed to crane jibs must be reported to the ship owner/manager and advice sought before carrying out any kind of repair.

Controls of lifting appliances

Controls of lifting appliances should be permanently and legibly

marked with their function and their operating directions shown by arrows

or other simple means, indicating the position or direction of movement for

hoisting or lowering, slewing or luffing, etc.

Make-shift extensions should not be fitted to controls nor any

unauthorised alterations made to them. Foot-operated controls should

have slip resistant surfaces.

No lifting device should be used with any locking pawl, safety

attachment or device rendered inoperative. If, exceptionally, limit switches

need to be isolated in order to lower a crane to its stowage position, the

utmost care should be taken to ensure the operation is completed safely.

Safety measures

A powered appliance should always have a person at the controls

while it is in operation; it should never be left to run with a control secured

in the "ON" position.

If any powered appliance is to be left unattended with the power

on, loads should be taken off and controls put in "NEUTRAL" or "OFF"

positions. Where practical, controls should be locked or otherwise

inactivated to prevent accidental restarting. When work is completed, power

should be shut off.

The person operating any lifting appliance should have no other

duties which might interfere with their primary task. They should be in a

proper and protected position, facing controls and, so far as is practicable,

with a clear view of the whole operation.

Where the operator of the lifting appliance does not have a clear

view of the whole of the path of travel of any load carried by that applianc

appropriate precautions should be taken to prevent danger. Generally this

requirement should be met by the employment of a competent and

properly trained signaller designated to give instructions to the operator. A

signaller includes any person who gives directional instructions to an

operator while they are moving a load, whether by manual signals, by radio

or otherwise.

The signaller should have a clear view of the path of travel of the

load where the operator of the lifting appliance cannot see it.

Where necessary, additional signallers should be employed to giv

instructions to the first signaller.

Every signaller should be in a position that is:-

(a) safe; and

(b) in plain view of the person to whom they are signalling unless an

effective system of radio or other contact is in use.

All signallers should be instructed in and should follow a clear cod

of signals, agreed in advance and understood by all concerned in the

operation.

If a load can be guided by fixed guides, or by electronic means, or

some other way, so that it is as safely moved as if it was being controlled by

competent team of driver and signallers, signallers will not be necessary.

Positioning and installation

Permanently installed lifting equipment should not be used unless

it has been positioned or installed in such a way as to minimise the risk of

any of the following occurrences-

(a) the equipment or a load striking a worker;

(b) a load drifting dangerously or falling freely;

(c) a load being released unintentionally.

More on general cargo ship :

- Rope handling safe procedure

Ropes are made of short fibres that are spun into yarns,

which are then made into flat or twisted strands.

And the strands are spun or braided to make the finished

rope .

More .....

-

Synthetic man-made ropes and hawsers

Although natural fibre ropes are still widely used throughout the marine industry, they have been superseded by synthetic fibres for a great many

purposes. Not only do the majority of synthetic ropes have greater strength

than their natural fibre counterparts, but they are more easily obtainable

and at present considerably cheaper.

More .....

-

Natural fibre rope

All natural fibre rope is manufactured from manilla, sisal, hemp, coir, cotton

or flax fibres.The process of manufacture consists of twisting the fibres

into yarns and turning the yarns in an opposite direction to establish the

strands.

More .....

-

Lay of Ropes and hawsers - Small Stuff descriptions

The lay of rope is a term used to describe the nature of the twist that produces the complete rope .The most common form of rope at sea is known as ‘hawser laid rope’ comprising three strands laid up right- or lefthanded.

More .....

- Stresses in ship structures and how to mitigate

Heavy weights tend to cause a downward deflection of the deck area supporting the load .This subsequently produces stresses, with

consequent inward and outward deflections of supporting bulkheads,

depending on the position of initial loading .

More .....

- Anchoring safe practice

Prior approaching an area for anchoring ships master should investigate fully a suitable anchoring position and conduct a planned approach including speed reduction in ample time and orienting the ships head prior anchoring to same as similar sized vessels around or stem the tide or wind whichever is stronger . Final decision to be made on method of anchoring to be used , the number of shackles , the depth of water, expected weather and holding ground. .

More .....

- MacGregor single-pull weather-deck hatch cover

Hatch covers are used to close off the hatch opening and make it

watertight. Wooden hatch covers, consisting of beams and boards over

the opening and covered with tarpaulins, were once used but are no

longer fitted. Steel hatch covers, comprising a number of linked steel

covers, are now fitted universally. Various designs exist for particular

applications, but most offer simple and quick opening and closing,

which speed up the cargo handling operation..

More .....

- Cargo holds access arrangement

The access shall be separate from the hatchway opening, and shall be by a stairway if possible. A fixed ladder, or a line of fixed rungs, shall have no point where they fill a reverse slope

.

More .....

- Prepare cargo holds prior loading

Washing is always carried out after the compartment has been swept. Drying time for washed compartments must be allowed for, before loading the next cargo; this time will vary with the climate, but two to three days must be expected.

More .....

- Strength and stability of the Lifting appliances

The vessel's structure, crane, derrick or other lifting device and the supporting structure should be of sufficient strength to withstand the loads

that will be imposed when operating at its maximum load moment .

More .....

- Lifting appliances - Maintenance, testing, controls & safety measures

When there is any suspicion that any appliance or item of

equipment may have been subjected to excessive loads, exceeding the Safe

Working Load (SWL), or subjected to treatment likely to cause damage, it

should be taken out of service until it can be subjected to a thorough

examination by a competent person.

More .....

- Safe operation of Lifting appliances and gears

All lifting operations must be properly planned, appropriately

supervised and carried out to protect the safety of workers.

More .....

- Derricks for lifting cargo on board

Derricks for lifting cargo on board is required to be of adequate strength and stability for each load, having regard in particular to the stress induced at its mounting or fixing points , securely anchored, adequately ballasted or counterbalanced and supported by outriggers

as necessary to ensure its stability when lifting.

More .....

- Deck cranes

Deck cranes have a number of advantages, the rigging

time being negligible, and the crane is able to pick up and land permitted

loads anywhere within its working radius. The safe working loads of cranes

is generally of the order of 10 to 15 tonnes and larger cranes are available

capable of lifts from 30 to 40 tonnes..

More .....

- Characteristics of Marine paints

Paint consists of pigment dispersed in a liquid referred to as the ‘vehicle’.

When spread out thinly the vehicle changes in time to an adherent dry film.

The drying may take place through one of the following processes..

More .....

- Protection by Means of Paints

It is often assumed that all paint coatings prevent attack on the metal

covered simply by excluding the corrosive agency, whether air or water. This

is often the main and sometimes the only form of protection; however there

are many paints which afford protection even though they present a porous

surface or contain various discontinuities. .

More .....

- Role classification societies maintaining seaworthiness of vessels

classification societies publish rules and regulations which are principally concerned with the strength of the ship, the provision of adequate equipment, and the reliability of the machinery .

More .....

- Periodic survey requirement by classification societies

To maintain the assigned class all steel ships are required to be surveyed and examined by the Society’s

surveyors at regular periods.

The major hull items to be examined at these surveys only are discussed

here..

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||