Home page||General service system ||

Ballast arrangements & procedure for ship service systems

The ballasting of a vessel which is to proceed without cargo to the loading port is necessary for a safe voyage, sometimes in heavy weather conditions. On arrival at the port the large amount of ballast must be discharged rapidly in readiness for loading.

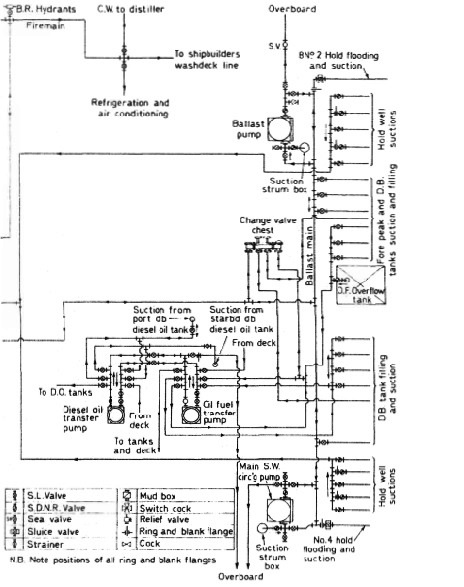

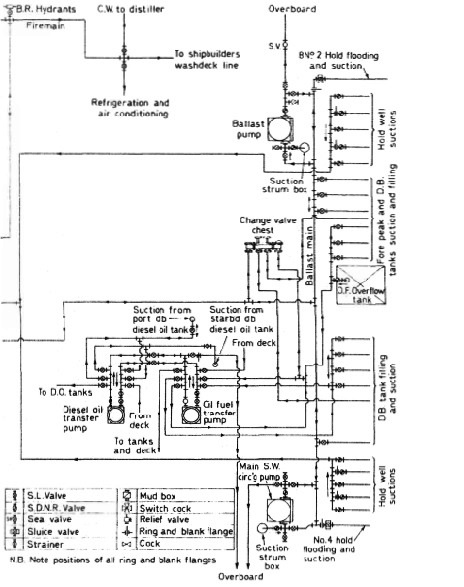

Ballast pump capacity is governed by the volume of water that has to be discharged in a given time. The ballast pump is often also the stand-by sea-water circulating pump (Figure down) but very large ballast discharge capacity is necessary for some ships.

Vessels with tanks available for either ballast or oil fuel are fitted with a change-over chest or cock designed to prevent mistakes. An oily water separator on the ballast pump discharge would prevent discharge of oil with the ballast from a tank that had been used for fuel or oil cargo. Ballast carried in the empty cargo tanks of crude oil carriers has potential for pollution when discharged, particularly if cargo pumps are used for the purpose. Only very large oil/water separators have the capacity to reduce this pollution.

Segregated ballast tanks with dedicated ballast pumps prevent the problem. An example of a ballast pump for a segregated ballast tank, .

Fore and aft peak tanks, double bottom and deep tanks used for ballast in dry cargo vessels as well as ballast spaces in bulk liquid carriers, can be dangerous due to lack of oxygen or the presence of harmful gases. Oxygen may be depleted by corrosion and harmful gases may be produced by organisms or pollutants in the water.

The ballast water from some areas has been found to carry dangerous bacteria. Ballast tank air and overflow pipes must be of the required size relative to the filling lines, that is, 25% greater in area and, in any case, not less than 50mm bore. They are fitted at the highest part of the tank or at the opposite end to the filling connection. Tanks used for fuel storage also have to fulfil the requirements for fuel tanks.

Nameplates are attached to the tops of all air pipes and sounding pipes must have means of identification. The latter are to be of steel with a striker plate at the bottom and must conform to the various rulings. The pipelines for ballasting must be of adequate strength and if of steel, protected by galvanizing or other means. The ballasting of some tanks, such as those in the double bottoms, is carried out by running up by opening appropriate valves, rather than by pumping. Remotely operated valves are installed with modern ballast systems. Pump and valve controls are then centrally located. Centrifugal pumps with water ring primers, used for ballast pumping, are suitable for use as statutory bilge pumps.

Figure : Bilge ballast fuel main

Figure : Bilge ballast fuel main

Air pipes are provided for all tanks to prevent air being trapped under

pressure in the tank when it is filled, or a vacuum being created when it is

emptied. The air pipes may be fitted at the opposite end of the tank to the

filling pipe and/or at the highest point of the tank. Each air pipe from a

double bottom tank, deep tanks which extend to the ship’s side, or any tank

which may be run up from the sea, is led up above the bulkhead deck. From

oil fuel and cargo oil tanks, cofferdams, and all tanks which can be pumped

up, the air pipes are led to an open deck, in a position where no danger will

result from leaking oil or vapours. The heights above decks and closing

arrangements are covered by the Load Line Conditions of Assignment .

Sounding pipes

Sounding pipes are provided to all tanks, and compartments not readily

accessible, and are located so that soundings are taken in the vicinity of the

suctions, i.e. at the lowest point of the tank. Each sounding pipe is made as

straight as possible and is led above the bulkhead deck, except in some

machinery spaces where this might not be practicable. A minimum bore of

32 mm is in general required for sounding pipes; but where they pass

through refrigeration spaces, to allow for icing, a minimum bore of 65mm

is required where the temperature is at 0 °C or less. Underneath the sounding

pipe a striking plate is provided where the sounding rod drops in the

bilge well, etc. Sometimes a slotted sounding pipe is fitted to indicate the

depth of liquid present, and the closed end must be substantial to allow for

the sounding rod striking it regularly. Various patent tank sounding devices

are available and can be fitted in lieu of sounding pipes, as long as they

satisfy the requirements of the classification society.

Scupper arrangement

Scuppers are fitted at the ship’s side to drain the decks.

Below the freeboard decks and within intact houses on the freeboard deck

these scuppers are led to the bilges. They may alternatively be led overboard

if they are above the waterline, and are fitted with a non-return

valve operated from above the freeboard deck. Those scuppers at a reasonable

distance above the waterline may be fitted with two or possibly one

automatic non-return valve which does not have positive means of closing

. Scuppers draining open decks above the freeboard decks

are led directly overboard

Summarized below some of the basic procedure of machinery service systems and equipment :

- Ballast arrangements

The ballasting of a vessel which is to proceed without cargo to the loading port is necessary for a safe voyage, sometimes in heavy weather conditions. On arrival at the port the large amount of ballast must be discharged rapidly in readiness for loading....

- Cargo ships bilge systems

The essential purpose of a bilge system, is to clear water from the ship's 'dry' compartments, in emergency. The major uses of the system, are for clearing water and oil which accumulates in machinery space bilges as the result of leakage or draining, and when washing down dry cargo holds. The bilge main in the engine room, has connections from dry cargo holds, tunnel and machinery spaces.....

- Bilge system layout details

All bilge suctions have screw down non-return valves with strainers or mud boxes at the bilge wells. Oily bilges and purifier sludge tanks have suitable connections for discharge to the oily water separator or ashore. The system is tailored to suit the particular ship......

- Domestic water system

Systems using gravity tanks to provide a head for domestic fresh and sanitary water, have long been superseded by schemes where supply pressure is maintained by a cushion of compressed air in the service tanks....

- Reverse osmosis

Osmosis is the term used to describe the natural migration of water from one side of a semi-permeable membrane into a solution on the other side. The

phenomenon occurs when moisture from the soil passes through the membrane covering of the roots of plants,....

- Salinometer features

The condensate or product, if of acceptable quality, is delivered to the appropriate tanks by the distilled water pump. Quality is continuously tested by the salinometer both at start up and during operation. If the device registers an excess of salinity it will dump the product and activate the alarm using its solenoid valves. The product is recirculated in some installations......

- Sewage systems

The exact amount of sewage and waste water flow generated on board ship is difficult to quantify. European designers tend to work on the basis of 70 litres/person/day of toilet waste (including flushing water) and about 130-150 litres/person/day of washing water (including baths, laundries, etc.). US authorities suggest that the flow from toilet discharges is as high as 114 litres/person/day with twice this amount of washing water......

- Sewage zero discharge system

A retention or holding tank is required where no discharge of treated or untreated sewage is allowed in a port area. The sewage is pumped out to shore reception facilities or overboard when the vessel is proceeding on passage at sea, usually beyond the 12 nautical mile limit. ...

- Biological sewage treatment

A number of biological sewage treatment plant types are in use at sea but nearly all work on what is called the extended aeration process. Basically this consists of oxygenating by bubbling air through or by agitating the surface. ....

- Sterilization system

Sterilization by the addition of chlorine, is recommended in Merchant Shipping Notice M1214. A later notice, M1401, states that the Electro-Katadyn process in use since the 1960s, has also been approved. Another problem with distilled water is that having none of the dissolved solids common in fresh water it tastes flat. It also tends to be slightly acidic due to its ready absorption of carbon dioxide (CO2). .....

- Treatment of water from shore

There is a risk that water supplied from ashore may contain harmful organisms which can multiply and infect drinking or washing water storage tanks. All water from ashore, whether for drinking or washing purposes, is to be sterilized. When chlorine is used, the dose must be such as to give a concentration of 0.2 ppm....

- Water production low pressure evaporator

A considerable amount of fresh water is consumed in a ship. The crew uses on average about 70 litre/person/day and in a passenger ship, consumption can be as high as 225 litre/person/day. Water used in the machinery spaces as make up for cooling system losses may be fresh or distilled but distilled water is essential for steam plant where there is a water tube boiler.

Steamship consumption for the propulsion plant and hotel services can be as high as 50 tonnes/day.....

- Flash evaporator system

The evaporator , boils sea water at the saturation temperature corresponding to the uniform pressure through the evaporation and condensing chambers. With flash evaporators the water is heated in one compartment before being released into a second chamber in which the pressure is substantially lower......

- Oil content monitor system

In the past, an inspection glass, fitted in the overboard discharge pipe of the oil/water separator permitted sighting of the flow. The discharge was illuminated by a light bulb fitted on the outside of the glass port opposite the viewer......

- Oily water separator

Oil/water separators are necessary aboard vessels to prevent the discharge of oil overboard mainly when pumping out bilges. They also find service when deballasting or when cleaning oil tanks. The requirement to fit such devices is the result of international legislation....

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||