Home page||General service system ||

Biological sewage treatment - Ship service systems

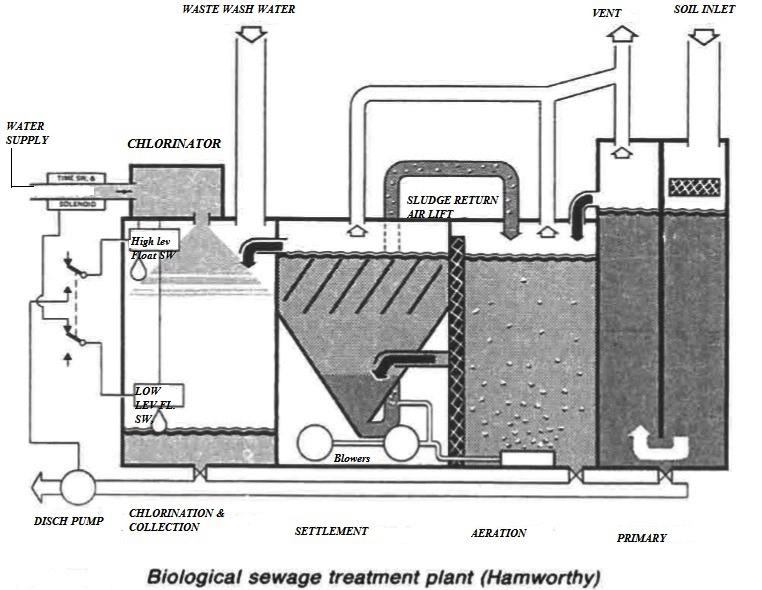

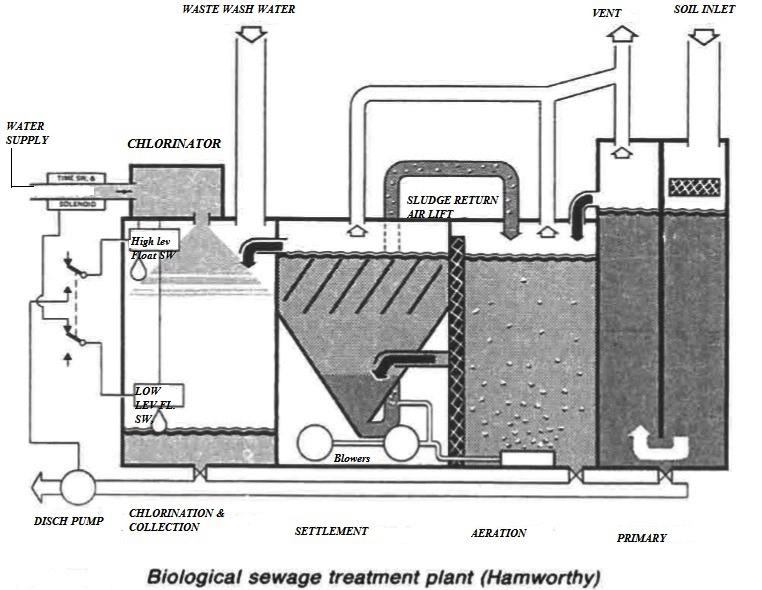

A number of biological sewage treatment plant types are in use at sea but nearly all work on what is called the extended aeration process. Basically this consists of oxygenating by bubbling air through or by agitating the surface. By so doing a family of bacteria is propagated which thrives on the oxygen content and digests the sewage to produce an innocuous sludge. In order to exist, the bacteria need a continuing supply of oxygen from the air and sewage

wastes.

If plant is shut down or bypassed or if the air supply fails, the bacteria die and the plant cannot function correctly until a new bacteria colony is generated. Change of flushing liquid — as when a ship moves from a sea-water environment to fresh water — drastic change of temperature or excess use of lavatory cleaning agents can also affect the bacteria colony. The process of regeneration can take several days depending on the level of harm caused. Bacteria which thrive in the presence of oxygen are said to be aerobic. When oxygen is not present, the aerobic bacteria cannot live but a different family of

bacteria is generated. These bacteria are said to be anaerobic. Whilst they are equally capable of breaking down sludge, in so doing they generate gases such as hydrogen sulphide and methane.

Continuing use of a biological sewage system after a failure of the air supply, could result in propagation of anaerobic bacteria and processes. The gases produced by anaerobic activity are dangerous, being flammable and toxic. Extended aeration plants used at sea are package plants consisting basically of three inter-connected tanks (Figure below).

The effluent may be comminuted (i.e. passed through a device which consists of a rotating knife-edge drum which acts both as a filter and a cutter) or simply passed through a bar screen from where it passes into the first chamber. Air is supplied to this chamber via a diffuser which breaks the air up into fine bubbles. The air is forced through the diffuser by a compressor. After a while a biological sludge is formed and this is dispersed throughout the tank by the agitation caused by the rising air bubbles. The liquid from the aeration tank passes to a settling tank where under quiescent conditions, the activated sludge, as it is known, settles and leaves a clear effluent.

The activated sludge cannot be allowed to remain in the settling tank since there is no oxygen supplied to this area and in a very short time the collected sludge would become anaerobic and give off offensive odours. The sludge is therefore continuously recycled to the aeration tank where it mixes with the incoming waste to assist in the treatment process. Over a period of time the quantity of sludge in an aeration tank increases due to the collection of inert residues resulting from the digestion process, this

build up in sludge is measured in ppm or mg/litre, the rate of increase being a function of the tank size. Most marine biological waste treatment plants are designed to be desludged at intervals of about three months.

The desludging operation entails pumping out about three quarters of the aeration tank contents and refilling with clean water. The clear effluent discharged from a settling tank must be disinfected to reduce the number of coliforms to an acceptable level. Disinfection is achieved by treating the clean effluent with a solution of calcium or sodium hypochlorite, this is usually carried out in a tank or compartment on the end of the sewage treatment unit.

The chlorinator shown in Figure below uses tablets of calcium hypochlorite retained in perforated plastic tubes around which the clean effluent flows dissolving some of the tablet material as it does so. The treated effluent is then held in the collection tank for 60 minutes to enable the process of disinfection to be completed. In some plants the disinfection is carried out by ultra-violet radiation.

Figure : Biological sewage treatment plant (Hamworthy)

Summarized below some of the basic procedure of machinery service systems and equipment :

- Ballast arrangements

The ballasting of a vessel which is to proceed without cargo to the loading port is necessary for a safe voyage, sometimes in heavy weather conditions. On arrival at the port the large amount of ballast must be discharged rapidly in readiness for loading....

- Cargo ships bilge systems

The essential purpose of a bilge system, is to clear water from the ship's 'dry' compartments, in emergency. The major uses of the system, are for clearing water and oil which accumulates in machinery space bilges as the result of leakage or draining, and when washing down dry cargo holds. The bilge main in the engine room, has connections from dry cargo holds, tunnel and machinery spaces.....

- Bilge system layout details

All bilge suctions have screw down non-return valves with strainers or mud boxes at the bilge wells. Oily bilges and purifier sludge tanks have suitable connections for discharge to the oily water separator or ashore. The system is tailored to suit the particular ship......

- Domestic water system

Systems using gravity tanks to provide a head for domestic fresh and sanitary water, have long been superseded by schemes where supply pressure is maintained by a cushion of compressed air in the service tanks....

- Reverse osmosis

Osmosis is the term used to describe the natural migration of water from one side of a semi-permeable membrane into a solution on the other side. The

phenomenon occurs when moisture from the soil passes through the membrane covering of the roots of plants,....

- Salinometer features

The condensate or product, if of acceptable quality, is delivered to the appropriate tanks by the distilled water pump. Quality is continuously tested by the salinometer both at start up and during operation. If the device registers an excess of salinity it will dump the product and activate the alarm using its solenoid valves. The product is recirculated in some installations......

- Sewage systems

The exact amount of sewage and waste water flow generated on board ship is difficult to quantify. European designers tend to work on the basis of 70 litres/person/day of toilet waste (including flushing water) and about 130-150 litres/person/day of washing water (including baths, laundries, etc.). US authorities suggest that the flow from toilet discharges is as high as 114 litres/person/day with twice this amount of washing water......

- Sewage zero discharge system

A retention or holding tank is required where no discharge of treated or untreated sewage is allowed in a port area. The sewage is pumped out to shore reception facilities or overboard when the vessel is proceeding on passage at sea, usually beyond the 12 nautical mile limit. ...

- Biological sewage treatment

A number of biological sewage treatment plant types are in use at sea but nearly all work on what is called the extended aeration process. Basically this consists of oxygenating by bubbling air through or by agitating the surface. ....

- Sterilization system

Sterilization by the addition of chlorine, is recommended in Merchant Shipping Notice M1214. A later notice, M1401, states that the Electro-Katadyn process in use since the 1960s, has also been approved. Another problem with distilled water is that having none of the dissolved solids common in fresh water it tastes flat. It also tends to be slightly acidic due to its ready absorption of carbon dioxide (CO2). .....

- Treatment of water from shore

There is a risk that water supplied from ashore may contain harmful organisms which can multiply and infect drinking or washing water storage tanks. All water from ashore, whether for drinking or washing purposes, is to be sterilized. When chlorine is used, the dose must be such as to give a concentration of 0.2 ppm....

- Water production low pressure evaporator

A considerable amount of fresh water is consumed in a ship. The crew uses on average about 70 litre/person/day and in a passenger ship, consumption can be as high as 225 litre/person/day. Water used in the machinery spaces as make up for cooling system losses may be fresh or distilled but distilled water is essential for steam plant where there is a water tube boiler.

Steamship consumption for the propulsion plant and hotel services can be as high as 50 tonnes/day.....

- Flash evaporator system

The evaporator , boils sea water at the saturation temperature corresponding to the uniform pressure through the evaporation and condensing chambers. With flash evaporators the water is heated in one compartment before being released into a second chamber in which the pressure is substantially lower......

- Oil content monitor system

In the past, an inspection glass, fitted in the overboard discharge pipe of the oil/water separator permitted sighting of the flow. The discharge was illuminated by a light bulb fitted on the outside of the glass port opposite the viewer......

- Oily water separator

Oil/water separators are necessary aboard vessels to prevent the discharge of oil overboard mainly when pumping out bilges. They also find service when deballasting or when cleaning oil tanks. The requirement to fit such devices is the result of international legislation....

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||