Home page||Ship employment

||

Reefer chamber temperature control- Respiration and Ventilation technics

"Refrigerated cargo" implies a reduction of the temperature of the cargo below the ambient air temperature.

Refrigerated cargoes fall into two distinct groups; those carried under "temperature controlled" conditions,

e.g. fresh fruit and vegetables in the zero to 15°C range, and those carried under "frozen" conditions,

e.g. meat and fish at a temperature of 18°C or lower. This section deals with general principles of

refrigeration as they affect cargoes subject to temperature control.

Increasing volumes of cargo are being carried under temperature control and knowledge of the principles

behind this form of carriage is essential. In most instances, the shipper will give specific carriage instructions

but there are some general principles that apply to all temperature controlled cargoes.

Temperature Control -

Prevention of Damage by Micro-organisms

Almost all organic matter is constantly under attack by micro-organisms such as yeasts, moulds or

bacteria which, like all living things, require adequate moisture and an appropriate temperature to enable

them to grow. In general, the higher the temperature, the faster the rate of growth. For example, the rate of

growth of almost all micro-organisms doubles for every 10°C increase in temperature. Equally, the rate of

growth halves for each 10°C reduction in temperature. However, there are upper and lower limits to this

effect.

For most micro-organisms, the rate of growth at temperatures below zero is very small while most

will not grow at temperatures above about 45°C. Thus, carrying an organic cargo at a lower temperature will

tend to slow down the rate at which it can be damaged by micro-organisms because they grow at a much

slower rate.

Prevention of Changes in the Cargo

Many temperature controlled cargoes are alive. The best known examples of live cargo are fresh fruit

and vegetables, but there are many others, e.g. most cereal grains and some timber. As a part of their life

processes living organisms respire, i.e. they take in oxygen and give out carbon dioxide in exactly the same

way as animals. This process creates energy to drive the life processes within the organism and produces

heat as a side effect.

This is another reason why some cargoes must be refrigerated. For example, if the heat of respiration is

not removed from a cargo of fresh fruit, the increased temperature within the cargo will induce chemical

changes in the composition of the fruit which, in turn, will permit physical changes that cause the cargo

to deteriorate. Thus, pears carried at ambient temperature will warm up, thereby increasing their rate of

ripening. As they ripen, they become softer and are more prone to bruising irrespective of how well they

have been packed and stowed.

Respiration and Ventilation

Respiration -

Many living cargoes absorb oxygen from the air in the hold and give out carbon

dioxide as a consequence of their life processes. Undressed timber, i.e. logs from which the bark has not

been stripped, also produce carbon dioxide. In unventilated holds, carbon dioxide can reach dangerous

levels, and there have been cases of seamen suffocating by entering such holds without breathing apparatus.

Fruits and some vegetables also produce ethylene during ripening. This gas is a natural plant hormone

and can induce ripening of other fruits and vegetables stowed in the same hold. If adjacent compartments

are interconnected by a common system of air ducts, then the production of ethylene in one compartment

can induce ripening in the others.

Ventilation

From the above, it will be apparent that it is essential for refrigerated cargo holds to be properly ventilated

in order to replace the cargo space air with fresh air thus sweeping out the ethylene and preventing or

delaying the early ripening of the cargo. Ventilation also reduces the level of carbon dioxide within the hold

often with beneficial effects on the cargo. It is difficult to measure ethylene directly in the air within a cargo

hold, so it is usual to measure the level of carbon dioxide and to use this as a guide to the ethylene level.

The carriage instructions for fruit and vegetables should include a value for the maximum acceptable level

of carbon dioxide in the hold air.

Some fruits can benefit from an increased level of carbon dioxide within a hold as levels above a certain

value actually slow down the respiration of the fruit and delay the onset of ripening. It is the composition

of the air that influences the cargo and not just the level of carbon dioxide. The effects of both oxygen and

carbon dioxide levels must be considered when deciding how to carry a particular cargo.

In general, a reduction in the amount of oxygen present tends to retard the rate of respiration and hence

prolong cargo life. Air contains 21% oxygen and this level needs to be reduced to about 10% before any

real effect on the rate of respiration is seen. Since the rate of respiration is dependent on temperature, it

follows that the lower the temperature in the cargo the lower the oxygen concentration can fall without

causing other problems. Fruit and vegetables may also be sensitive to low oxygen concentrations and to low

temperatures which can cause physical disorders, leading to quality deficiencies.

An increase in the carbon dioxide level is beneficial to some fruits since it tends to delay the onset of

ripening. Air contains about 0.034% of carbon dioxide, and the addition of only a few percent to the air in

the hold can have a marked effect on respiration, leading to prolonged life for the fruit. However, if carbon

dioxide levels are permitted to rise too much then damage to the cargo may occur.

In recent years, new developments in refrigeration techniques have led to the introduction of "controlled

atmosphere" (C.A.) as a means of prolonging the life and quality of various commodities. The process is

now relatively common in both reefer ships and containers.

Refrigeration and Moisture

As air cools, its capacity to hold moisture becomes lower and this is usually seen in refrigeration circuits

by ice forming on the cooler coils. In a closed circuit where cooling air is recirculated through holds without

any access to the outside, there tends to be a drying effect on the cargo. If fresh fruit is exposed to constant

cooling air, e.g. an apple placed in a domestic refrigerator, moisture will be extracted from the fruit by the

cooling air. This leads eventually to deterioration of the fruit which becomes dry and wrinkled as it loses

moisture. Most cargoes are protected to some extent by their packaging, but even so the drying effect is very

real and can be the cause of damage.

Ideally, such cargoes should be carried at a controlled humidity as well as a controlled temperature.

Modern refrigerated ships are able to cope with this problem and required relative humidity levels are

usually specified in carriage instructions.

Stowage and Ventilation

Proper stowage of cargo destined to be refrigerated and hence ventilated is most important. Most

commodities are packed in cartons usually with an inner wrapping. While this may protect against drying

and physical damage, the packaging tends to restrict the free flow of cooling air. Thus, stowage becomes

extremely important in facilitating the flow of air.

The majority of refrigerated cargo offered for shipment in either reefer ship or container is palletised and

ensures proper air flow. However, on the rare occasions when a true break-bulk cargo is loaded (i.e. cartons

are loaded as individual pieces), it is important to ensure they are placed on dunnage or battens, leaving

adequate ventilation channels between adjacent blocks. If cartons have ventilation holes pierced in them,

then these must be placed "in register" to allow free entry of air. Stowage should be "box on box" and not

in "brick form".

Care should be taken to see that the cargo is stowed in accordance with the air flow within a compartment

and this will depend on the way in which cooled air enters the compartment. Different ships use different

refrigeration systems and the stowage of a particular cargo will be determined by the design of the individual

ship. In general, boxes and cartons should be stowed with their long axes in the same direction. Most reefers

have vertical air flow within compartments and it is advisable to place kraft paper or polythene sheeting

across the air vents that are not covered by cargo to avoid short circuits of the air flow.

Control of ventilation level

The importance of ventilation should not be underestimated.

Proper ventilation of fresh, chilled products is necessary to

remove the heat, carbon dioxide and other gases produced

by the cargo. Heat is removed by continuously circulating

the internal air, whereas carbon dioxide and other gases are

removed by replacing the internal air supply with cooled

fresh air.

Control of relative humidity level

Controlling the relative humidity level is also important when it

comes to controlling the quality of chilled products. The relative

humidity level affects many products, particularly the shelf

life of fruits and vegetables – and thus their condition upon

arrival.

If the humidity is too high, mould and/or fungi may

develop. If the humidity is too low, it may result in a higher

weight loss causing products to wilt and/or shrivel. For many

products, it is therefore important to be able to control the

relative humidity level during transport.

Please note that two different systems are used to either

decrease or increase the relative humidity level, depending

on the commodities involved.

How to control the atmosphere in a reefer container ?

Atmosphere control is another crucial variable in securing

the quality of chilled cargo. When fresh perishables are shipped

to distant markets, they require a precisely controlled

transport environment. It is well known that harvested fruits

and vegetables continue to live and breathe until they are

consumed or destroyed by decay or desiccation. Under

normal circumstances, these factors dictate the life span

of individual products.

The life span can, however, be prolonged by keeping the

commodities at their optimal temperature, combined with

the supply of the most effective blend of oxygen, carbon

dioxide and nitrogen.

By transporting products under Controlled Atmosphere,

the applied environment will slow down the ripening process

and extend the shelf life of the products.

For further details please refer to the Equipment section

of this brochure.

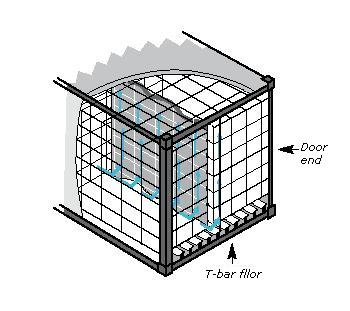

Fig: Reefer container inside

Cold treatment

The purpose of Cold Treatment is to exterminate insects

and larvae by maintaining a sufficiently low temperature

for a pre-determined period of time. The period of time and

temperature required are defined in protocols established

by phythosanitary authorities of the importing countries. If

the temperature rises above the established requirements,

the entire Cold Treatment process will fail and must either be

extended or started over again depending on the protocol.

Applying Cold Treatment eliminates the need to fumigate

cargo using insecticides, such as methyl bromide, which is

illegal in many countries.

Cold Treatment is primarily applied to various types of citrus

fruits, such as oranges, grapefruit and clementines. However,

kiwi fruit, apples, pears, grapes, lychees, loquats, etc. can also

be carried under Cold Treatment.

In order to reap the maximum benefits from the Cold

Treatment process, several factors are absolutely essential.

These factors include the correct pre-treatment, proper

pre-cooling of the products, optimal packaging and stowage,

as well as the constant monitoring at the terminals and on

board the vessels.

Other useful articles :

- Methods of refrigeration

Refrigeration is essentially the removal of heat through

the process of evaporation. We choose to refrigerate

commodities such as fruits and vegetables because we

want to prolong their “practical shelf life” – the time from

harvest until the product loses its commercial value.

More .....

-

Reefer cargo stuffing

it is essential that all products are treated correctly prior

to stuffing. Even though the temperature, ventilation and

humidity are all optimal during the entire voyage, products

will only arrive in perfect condition if the pre-treatment has

been performed correctly. Successful shipping begins at the

product sourcing area.

More .....

-

Growing demand for container refrigeration

On deck refrigerated containers are generally serviced by clip-on air cooled electric motor drive cooling units. The units are plugged into the

ships electrical system by way of suitable deck sockets.

More .....

-

Frozen products packaging requirement

Proper packaging procedures will help protect frozen cargo

during transport. Frozen products do not require air holes in

the top and bottom of the cartons. Air flowing around the load

is sufficient to remove heat that has penetrated the container.

The cartons should be stacked directly on top of each other to

take advantage of their strength in the corners.

More .....

- Packaging & stowage guideline for reefer cargo

Packaging plays an important role when it comes to protecting the cargo. The packaging material must be able

to support a stacking height of up to 2.4 metres (7’10’’).

The material should be able to withstand humidity without

collapsing, and should allow the passage of an adequate

vertical airflow through the cartons in order to maintain the

desired temperature..

More .....

- Choice of packaging for various commodities

Goods should be well stowed within the package,

evenly distributed and properly secured. Items

completely filling the case or carton contribute to

the strength of the whole package. Items which do

not completely fill the package must be cushioned

against shock or vibration.

More .....

- How to keep cargo fresh ?

Proper ventilation of fresh, chilled products is necessary to

remove the heat, carbon dioxide and other gases produced

by the cargo. Heat is removed by continuously circulating

the internal air, whereas carbon dioxide and other gases are

removed by replacing the internal air supply with cooled

fresh air..

More .....

- Loading precautions for refrigerated cargoes

Refrigerated cargoes include meat carcases, carton (packed) meat, fruit, cheese, butter, fish and offal. Ships are specifically designed for their carriage, with separate spaces in holds and ’tween decks, each fitted with suitable insulation and individual control of ventilation. Ordinary general cargoes may be carried in the spaces at other times, the temperature being regulated accordingly for the type of cargo being carried.

More .....

- Role classification societies maintaining seaworthiness of vessels

classification societies publish rules and regulations which are principally concerned with the strength of the ship, the provision of adequate equipment, and the reliability of the machinery .

More .....

- Periodic survey requirement by classification societies

To maintain the assigned class all steel ships are required to be surveyed and examined by the Society’s

surveyors at regular periods.

The major hull items to be examined at these surveys only are discussed

here..

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||