Home page||Ship employment

||

Reefer cargo stuffing- Pre-cooling, treatment & handling of a reefer container

Pre-treatment of reefer products prior stuffing

The condition of reefer products before they are stuffed plays an

important role in their condition upon arrival. That is why

it is essential that all products are treated correctly prior

to stuffing. Even though the temperature, ventilation and

humidity are all optimal during the entire voyage, products

will only arrive in perfect condition if the pre-treatment has

been performed correctly. Successful shipping begins at the

product sourcing area.

Pre-cooling of cargo

The proper pre-cooling of products will have a positive

effect on both shelf life and out turn, compared to products

that have not been pre-cooled. Reefer containers are built

primarily to maintain the temperature of the products,

therefore, products should always be pre-cooled to the

required carriage temperature prior to being loaded into

the container.

No pre-cooling of reefer container itself

Pre-cooling of the reefer container itself should never take

place. Once the doors of a pre-cooled container are opened,

hot ambient air will meet internal cold air, resulting in a large

amount of condensation on the interior surfaces.

As a result, condensed water may drip from the roof of the

container and cause stains and weaken the structure of the

boxes. Therefore, condensed water must be removed through

the evaporator located inside the reefer machinery. Heat that

enters the container during stuffing, combined with heat that

is constantly generated by the “respiring” cargo, must also be

removed through the evaporator.

As soon as water and heat pass the evaporator, ice is formed

and the machinery enters a short defrost mode. Consequently,

there will be less capacity available for cooling the cargo.

In a tropical climate with excessively hot and humid air, any

pre-cooling of the container is likely to cause problems and

damage the products.

Pre-cooling of the reefer container is only allowed when

the container is connected to the cold store and the

temperatures are identical. The connection is achieved by the

use of a “Cold Tunnel” – a tight duct between the cold store

and the container, which prevents ambient air from entering.

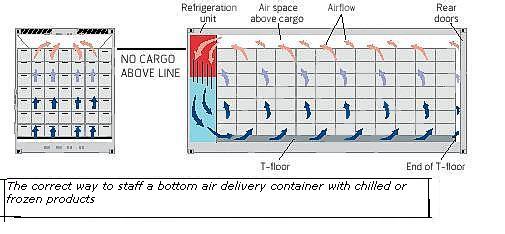

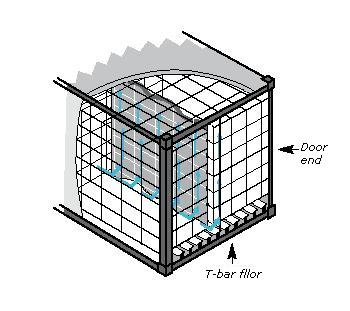

Fig 1 :Correct way of stuffing chilled cargo

Things to do during stuffing

The stuffing and placement of cargo will directly affect

the flow of air. Figure above illustrates the correct way to stuff

a bottom-air delivery reefer with chilled or frozen cargo.

In the case of chilled cargo, covering the entire floor with

cargo forces the cool air to flow through both the cartons

as well as the product, throughout the entire load. When

frozen cargo is stuffed in this manner, the cold air flows

around the cargo – blanketing the cartons and removing

any heat that enters the reefer container through the walls.

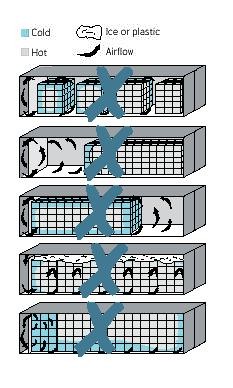

Fig 2 :Improperly stuffed chilled or frozen cargo

Things not to do during stuffing

Air always takes the path of least resistance. Here are a few

examples that illustrate reefer cargo which has

been stuffed improperly. In the first three examples, air tends

to “short circuit” or flow past the cartons/products rather

than through them. The last two examples illustrate restricted

airflow scenarios.

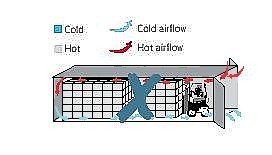

Never run a reefer with doors open

When the ambient temperature is warmer than the cargo,

operating the reefer with the rear doors open will not cool

down the cargo . Rather, the introduction of hot

ambient air will heat up the cargo. When hot humid air enters

the reefer, moisture condenses on the cold cooling coil and

turns to ice.

Cooled air escapes through the rear door, and the

cycle continues. Once stuffing is complete and the doors are

closed, the reefer could run for hours with a partially iced-up

cooling coil. This would reduce its cooling effect and put the

cargo in danger until the unit completes a defrost cycle.

Further, the genset should be stopped during stuffing,

due to the risk of exhaust gas reaching the fresh cargo.

Fig. 1 The correct way to stuff a bottom-air delivery

container with chilled or frozen cargo

To avoid cargo damage :

• do not leave any areas open or uncovered on the floor,

the front bulkhead or the side walls (if pallets are placed

at the front bulkhead, be sure to place cardboard under

empty pallets)

• do not run unit with rear doors open

• do not stuff cargo beyond the end of the T-floor

• do not plug channels at the end of the T-floor

• do not stuff cargo above the red load line

• do not put reefer set point at a temperature below what

is required for the cargo (this will not expedite the

cooling process)

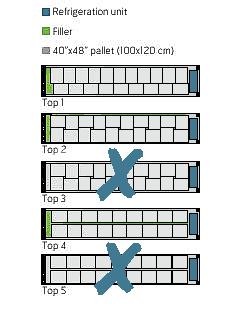

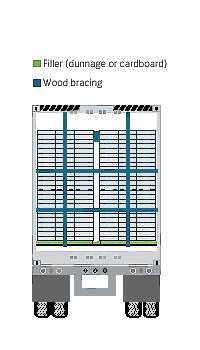

Fig 3 : Optimal stuffing of reefer cargo, Fig: Reefer container inside

Optimal stuffing – Top View

Covering the floor in a proper manner will improve the flow

of air and hence, refrigeration. In order to force air up and

through the cargo, the entire floor should be covered. Cover

the floor from the front bulkhead to the end of the T-floor.

Where the cargo does not cover the floor, some type of filler

should be used, such as dunnage or cardboard. Do not stuff

past the end of the T-floor with cargo or filler (fig. 3).

Fig 4 : Reefer stuffing for blocking or bracing cargo

Blocking and bracing

For blocking and bracing cargo, wood is still the preferred

material. Use wood as necessary (fig. 4), but do not nail wood

or dunnage to the container. Cover floor with a filler between

pallets to help force air through the cargo (as seen in the Top

4 view, fig. 4). Cover the ends of the last two pallets in order to

force air up and through the cartons. Do not block off airflow

past the end of the T-floor.

Other useful articles :

- Methods of refrigeration

Refrigeration is essentially the removal of heat through

the process of evaporation. We choose to refrigerate

commodities such as fruits and vegetables because we

want to prolong their “practical shelf life” – the time from

harvest until the product loses its commercial value.

More .....

-

Reefer cargo stuffing

it is essential that all products are treated correctly prior

to stuffing. Even though the temperature, ventilation and

humidity are all optimal during the entire voyage, products

will only arrive in perfect condition if the pre-treatment has

been performed correctly. Successful shipping begins at the

product sourcing area.

More .....

-

Growing demand for container refrigeration

On deck refrigerated containers are generally serviced by clip-on air cooled electric motor drive cooling units. The units are plugged into the

ships electrical system by way of suitable deck sockets.

More .....

-

Frozen products packaging requirement

Proper packaging procedures will help protect frozen cargo

during transport. Frozen products do not require air holes in

the top and bottom of the cartons. Air flowing around the load

is sufficient to remove heat that has penetrated the container.

The cartons should be stacked directly on top of each other to

take advantage of their strength in the corners.

More .....

- Packaging & stowage guideline for reefer cargo

Packaging plays an important role when it comes to protecting the cargo. The packaging material must be able

to support a stacking height of up to 2.4 metres (7’10’’).

The material should be able to withstand humidity without

collapsing, and should allow the passage of an adequate

vertical airflow through the cartons in order to maintain the

desired temperature..

More .....

- Choice of packaging for various commodities

Goods should be well stowed within the package,

evenly distributed and properly secured. Items

completely filling the case or carton contribute to

the strength of the whole package. Items which do

not completely fill the package must be cushioned

against shock or vibration.

More .....

- How to keep cargo fresh ?

Proper ventilation of fresh, chilled products is necessary to

remove the heat, carbon dioxide and other gases produced

by the cargo. Heat is removed by continuously circulating

the internal air, whereas carbon dioxide and other gases are

removed by replacing the internal air supply with cooled

fresh air..

More .....

- Loading precautions for refrigerated cargoes

Refrigerated cargoes include meat carcases, carton (packed) meat, fruit, cheese, butter, fish and offal. Ships are specifically designed for their carriage, with separate spaces in holds and ’tween decks, each fitted with suitable insulation and individual control of ventilation. Ordinary general cargoes may be carried in the spaces at other times, the temperature being regulated accordingly for the type of cargo being carried.

More .....

- Role classification societies maintaining seaworthiness of vessels

classification societies publish rules and regulations which are principally concerned with the strength of the ship, the provision of adequate equipment, and the reliability of the machinery .

More .....

- Periodic survey requirement by classification societies

To maintain the assigned class all steel ships are required to be surveyed and examined by the Society’s

surveyors at regular periods.

The major hull items to be examined at these surveys only are discussed

here..

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||