Home page||Refrigeration system||

Refrigeration systems - Chamber cooling arrangements

Refrigeration is used onboard a general cargo vessel in air conditioning systems , to cool bulk CO2 for fire

fighting systems , to preserve perishable foodstuffs during

transport or storage and in the carriage of some liquefied gases and bulk chemicals.

Chamber cooling arrangements

The refrigerant which boils off from the evaporator removes latent heat and provides the cooling action of the refrigerator circuit. The cooling effect provided by the evaporator can be used directly as described below in direct expansion grids but for better efficiency, the cooling effect is applied by circulation of air through the evaporator or direct expansion batteries.

To avoid having an extended refrigeration circuit for cargo cooling, a brine system can be used. The brine is cooled by the evaporator and in turn cools grids or batteries. Grids provide cooling which relies on convection and conduction but air circulated through brine batteries provides a positive through cooling effect.

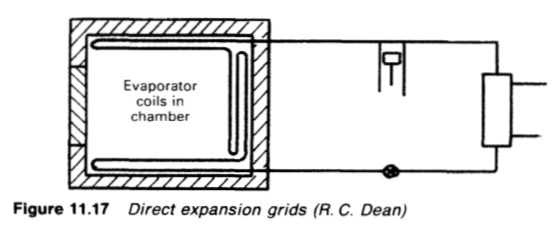

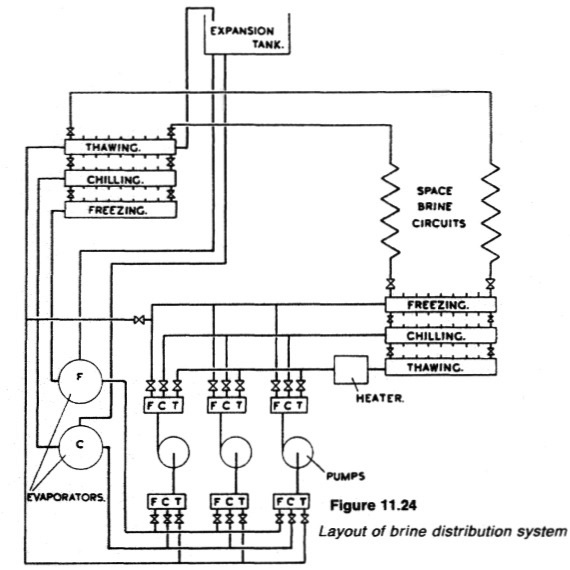

Direct expansion grids

Direct expansion grids (Figure 11.17) provide a simple means of cooling a small refrigerated chamber. Such a system could be costly in terms of the quantity of refrigerant required and the cooling would rely on convection currents. Leakage of refrigerant into the cargo space could be a problem. A further objection would be that multiple circuits of liquid refrigerant could give control problems.

Figure : Direct expansion grids (R. C. Dean)

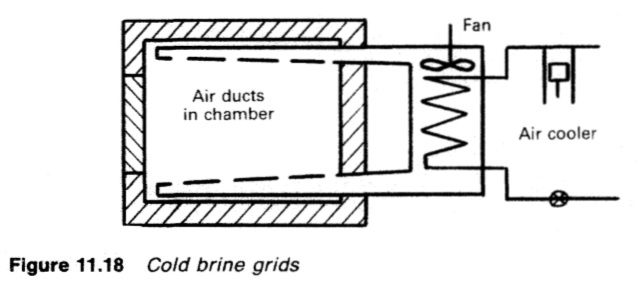

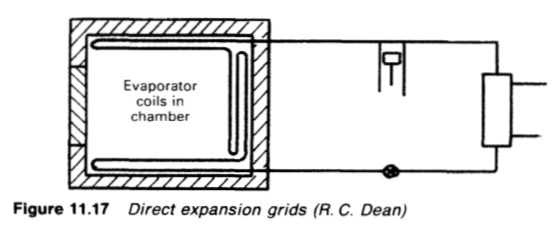

Cold brine grids

The pipe grids for this type of system (Figure 11.18) were arranged so that they cover as much as possible of the roof and walls of the chamber. The greatest coverage was needed on those surfaces which formed external boundaries and the least on divisional bulkheads and decks.

As the actual cooling of the cargo also depended on movement of air by natural convection, this type of chamber cooling required good, careful and ample dunnaging of the cargo stowage. This appreciably diminished the amount of cargo that could be carried so that the system is no longer favoured. Brine as a cooling medium (or secondary refrigerant) is cheap and easily regulated.

Figure : Cold brine grids

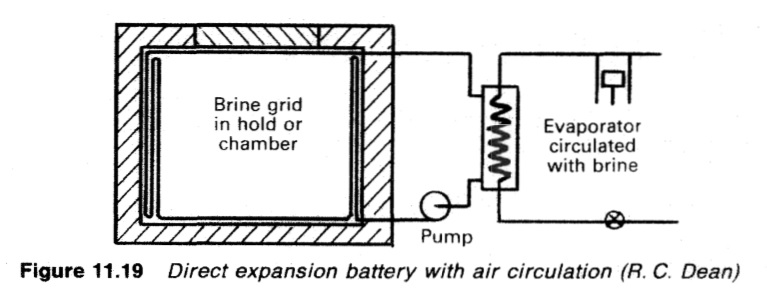

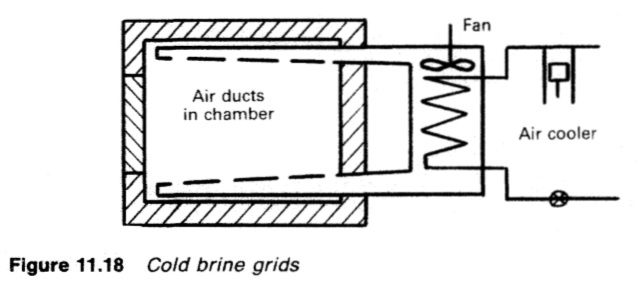

Direct expansion batteries and air

This is a commonly used system (Figure 11.19) where the refrigerant circulates through batteries enclosed in trunkings or casings. Air from the refrigerated chambers, is circulated through the batteries by fans. Its great advantages are economy in space, weight and cost, and also the use of circulated air as the cooling medium or secondary refrigerant.

Figure : Direct expansion battery with air circulation (R. C. Dean)

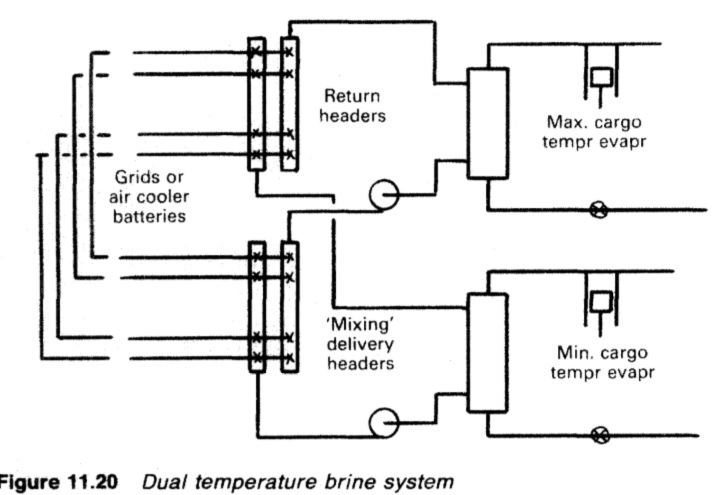

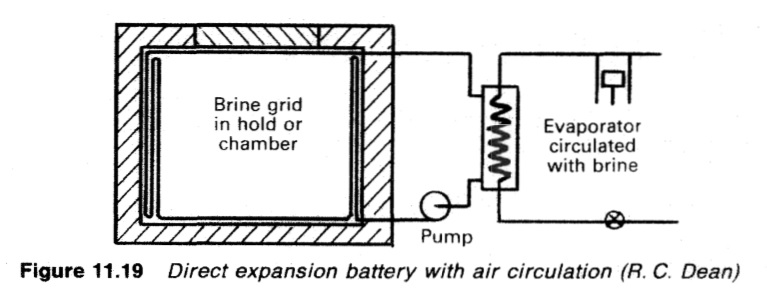

Brine battery and air

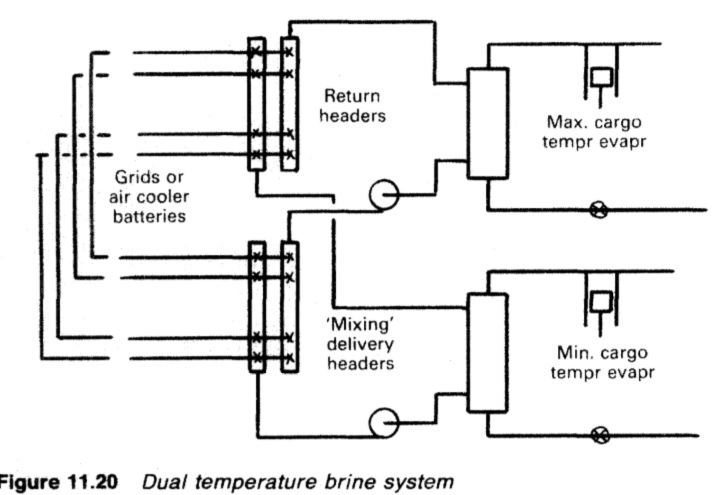

This system, in which brine instead of primary refrigerant is circulated through the batteries, continued to be employed for reefer ships carrying such cargoes as chilled meat or bananas where extremely close control of temperature was required when direct systems were gaining favour elsewhere. Brine is relatively easy to regulate.

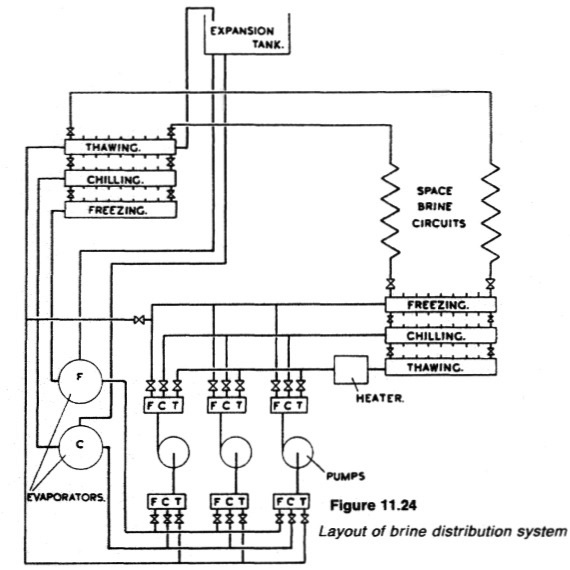

The system shown (Figure 11.20) is arranged with two separate refrigeration and brine circuits with connections from both brine systems to the air cooler batteries (or grids). (A more detailed diagram of a brine distribution system is shown in Figure 11.24.) Brine is inexpensive, being made with calcium chloride and fresh water to a gravity of about 1.25. Sodium dichromate or lime may be added to maintain the brine in an alkaline condition. Systems have been designed in which brine is replaced by one of the Glycols, for example ethylene glycol.

The glycols have the advantage of being non-corrosive, and may be used at much lower working temperatures than brine. Trichlorethylene has also been used as a secondary refrigerant, but has the disadvantages of being toxic and a solvent of many of the synthetic rubbers and other materials normally used as jointing.

Figure : Dual temperature brine system

Figure : Layout of brine distribution system

Air circulation systems

The design of an air circulating system is dictated principally by the allowable temperature spread in the cargo spaces and is not influenced by the type of air cooler in use. Brine and direct expansion systems have similar air circuits. The air cooler and fan unit are mounted behind a deck-to-deckhead screen or trunking at one side of the chamber with air being delivered and returned via trunking, false decks or deckheads provided with suitable openings.

The delivery openings are arranged with the largest furthest away from the fan where the air pressure is at its lowest and the smallest nearest to the fan. Correct cargo stowage is important as voids in the stow could allow the air to short circuit to the suction side of the cooler.

Cargo stowed adjacent to air inlets can become desiccated (dried out). For this reason and also to remove hot spots in the cargo, air circulation should be reversible. With ripening (live) cargoes, CO2 tends to accumulate in cargo spaces and it is necessary to limit the level by freshening the circulating air. Vents must be provided for this purpose.

Summarized below various refrigeration system components, working process and maintenance guideline:

- Automatic direct expansion refrigeration- vapour compression

The basic components of any refrigeration system (Figure 11.1) working on the

vapour compression cycle, are the compressor, condenser, expansion valve,

evaporator and the refrigerant fluid which is alternately vaporized and liquefied

during the refrigeration cycle. The temperature at which a fluid boils or

condenses, is known as the saturation temperature and varies with pressure....more

-

Choice of refrigerants

Theoretically, almost any liquid can be used as a refrigerant if its pressure/temperature relationship is suitable for the conditions. Although no perfect refrigerant is known, there are certain factors which determine a refrigerant's desirability for a particular duty and the one selected should possess as many as possible of the following

characteristics.....more

-

Refrigeration systems - Chamber cooling arrangements

To avoid having an extended refrigeration circuit for cargo cooling, a brine system can be used. The brine is cooled by the evaporator and in turn cools grids or batteries. Grids provide cooling which relies on convection and conduction but air circulated through brine batteries provides a positive through cooling effect.

.....more

-

Refrigeration system components

Marine condensers are generally of the shell and tube type, designed for high pressures. There may a few coil-in-casing or other types still in use. The coolant passes through the tubes with refrigerant condensing on the outside......more

-

Refrigeration system compressors

Refrigeration compressors are usually either reciprocating, or of the rotary

screw displacement type. Centrifugal and rotary vane compressors have also

been used.....more

-

Refrigeration systems expansion valves

The expansion valve is the regulator through which the refrigerant passes from the high pressure side of the system to the low pressure side. The pressure drop causes the evaporating temperature of the refrigerant to fall below that of the evaporator. .....more

- Monitoring instruments,CO2 measurement & Heat leakage and insulation test

All necessary cargo temperature readings are obtained on modern reefers and container ships on a data logger which makes an automatic record. The temperatures and pressures relating to refrigerant gas and liquid, cooling water, brine and the ambient are also required. Most of these are obtained from direct reading instruments.

.....more

- Marine condenser assembly

The temperature of the refrigerated spaces with a direct expansion system is controlled between limits through a thermostatic switch and a solenoid valve which is either fully open to permit flow of refrigerant to the room evaporator, or closed to shut off flow. The solenoid valve is opened when the sleeve moving upwards due to the magnetic coil hits the valve spindle tee piece and taps the valve open.....more

- Comparison between refrigerants R717 ammonia & R744 carbon dioxide

The ammonia used for refrigeration systems based on the use of a compressor,

condenser, expansion valve and an evaporator (Figure 11.2) is dry (anhydrous)

in that there is no water in solution with it. It has the chemical formula NH3 but

as a refrigerant, it is coded with the number R717....more

-

Container cooling system

The air is cooled either by brine or direct expansion batteries and the containers are arranged so that one cooler can maintain a stack of containers at a given temperature. The temperature of the return air duct for each container is monitored.....more

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||