Home page||Refrigeration system||

Comparison between refrigerants R717 ammonia & R744 carbon dioxide

R717 ammonia:

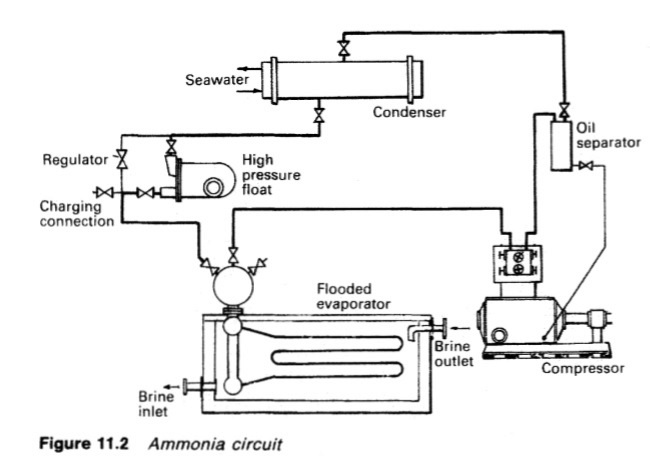

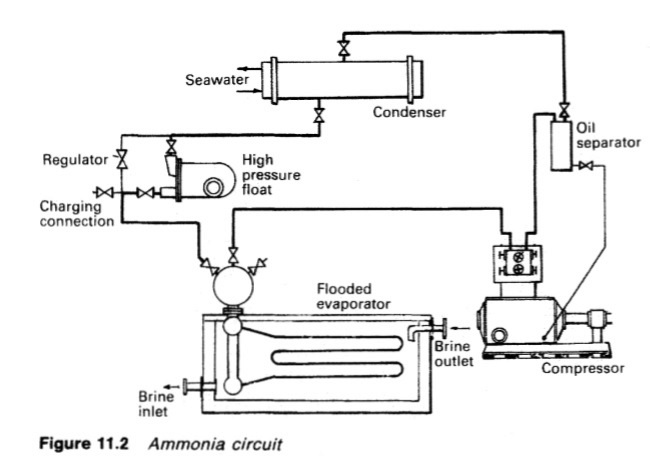

The ammonia used for refrigeration systems based on the use of a compressor,

condenser, expansion valve and an evaporator (Figure 11.2) is dry (anhydrous)

in that there is no water in solution with it. It has the chemical formula NH3 but

as a refrigerant, it is coded with the number R717.

The good qualities of

ammonia as a refrigerant have been offset by its toxicity, flammability and

pungent odour, so that carbon dioxide and then CFCs (which replaced CO2)

were used at sea in preference. Now that R12 is to be phased out in the short

term and R22 at a later date, ammonia is being considered as a replacement,

because despite its local harmful effects and disadvantages, it is ozone friendly.

The upper and lower explosive limits for pure ammonia in air, are 27% and

16% by volume, respectively. With oil contamination, the latter may reduce to

4%. Long-term exposure to ammonia should be restricted to the current

threshold limit value (TLV).

Exposure to higher concentrations of 1500 ppm

will result in damage to body tissue and death may result at 2500 ppm.

However, ammonia leaks are instantly detected at less than 10 ppm

concentration by the pungent odour and this is a safety feature. Very few

people can endure ammonia when its concentration exceeds the TLV. In the

liquid form, ammonia causes chemical and frost burns.

Corrosion of brass, bronze and similar alloys, occurs in ammonia systems if

there is any water present. These materials are avoided with steels being used

instead.

Ammonia is highly soluble in water with which it forms ammonium

hydroxide, a weak base. About 1300 volumes of ammonia can be dissolved in I

volume of water at low temperature. However it is easily expelled by boiling.

This action makes the vapour absorption refrigerator possible. Refrigerators, of

this type do not require a compressor for operation, only a heat source.

Figure : Ammonia circuit

R744 carbon dioxide

When carbon dioxide (CO2) is used as a refrigerant the working pressures are

high, being about 70 bar at the compressor discharge and 20 bar at the

compressor suction. The machinery and system must therefore be of

substantial construction. The critical temperature is low (31 degC) and this causes

problems in areas with high sea-water temperature. It also has a low coefficient

of performance. Poor miscibility with oil required that a drain system be

provided to remove oil continuously from the evaporator.

The gas is not explosive or flammable but a leak is potentially dangerous

because it can displace air and asphyxiate. It is also toxic. The liquid is stored in

steel bottles at high pressure, ideally in a cool space. A temperature rise will

cause a pressure rise in the bottles which is relieved by the rupturing of a safety

disc and release of gas.

Summarized below various refrigeration system components, working process and maintenance guideline:

- Automatic direct expansion refrigeration- vapour compression

The basic components of any refrigeration system (Figure 11.1) working on the

vapour compression cycle, are the compressor, condenser, expansion valve,

evaporator and the refrigerant fluid which is alternately vaporized and liquefied

during the refrigeration cycle. The temperature at which a fluid boils or

condenses, is known as the saturation temperature and varies with pressure....more

-

Choice of refrigerants

Theoretically, almost any liquid can be used as a refrigerant if its pressure/temperature relationship is suitable for the conditions. Although no perfect refrigerant is known, there are certain factors which determine a refrigerant's desirability for a particular duty and the one selected should possess as many as possible of the following

characteristics.....more

-

Refrigeration systems - Chamber cooling arrangements

To avoid having an extended refrigeration circuit for cargo cooling, a brine system can be used. The brine is cooled by the evaporator and in turn cools grids or batteries. Grids provide cooling which relies on convection and conduction but air circulated through brine batteries provides a positive through cooling effect.

.....more

-

Refrigeration system components

Marine condensers are generally of the shell and tube type, designed for high pressures. There may a few coil-in-casing or other types still in use. The coolant passes through the tubes with refrigerant condensing on the outside......more

-

Refrigeration system compressors

Refrigeration compressors are usually either reciprocating, or of the rotary

screw displacement type. Centrifugal and rotary vane compressors have also

been used.....more

-

Refrigeration systems expansion valves

The expansion valve is the regulator through which the refrigerant passes from the high pressure side of the system to the low pressure side. The pressure drop causes the evaporating temperature of the refrigerant to fall below that of the evaporator. .....more

- Monitoring instruments,CO2 measurement & Heat leakage and insulation test

All necessary cargo temperature readings are obtained on modern reefers and container ships on a data logger which makes an automatic record. The temperatures and pressures relating to refrigerant gas and liquid, cooling water, brine and the ambient are also required. Most of these are obtained from direct reading instruments.

.....more

- Marine condenser assembly

The temperature of the refrigerated spaces with a direct expansion system is controlled between limits through a thermostatic switch and a solenoid valve which is either fully open to permit flow of refrigerant to the room evaporator, or closed to shut off flow. The solenoid valve is opened when the sleeve moving upwards due to the magnetic coil hits the valve spindle tee piece and taps the valve open.....more

- Comparison between refrigerants R717 ammonia & R744 carbon dioxide

The ammonia used for refrigeration systems based on the use of a compressor,

condenser, expansion valve and an evaporator (Figure 11.2) is dry (anhydrous)

in that there is no water in solution with it. It has the chemical formula NH3 but

as a refrigerant, it is coded with the number R717....more

-

Container cooling system

The air is cooled either by brine or direct expansion batteries and the containers are arranged so that one cooler can maintain a stack of containers at a given temperature. The temperature of the return air duct for each container is monitored.....more

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||