Home page||Steering gears ||

Four ram gear with servo-controlled axial cylinder pumps

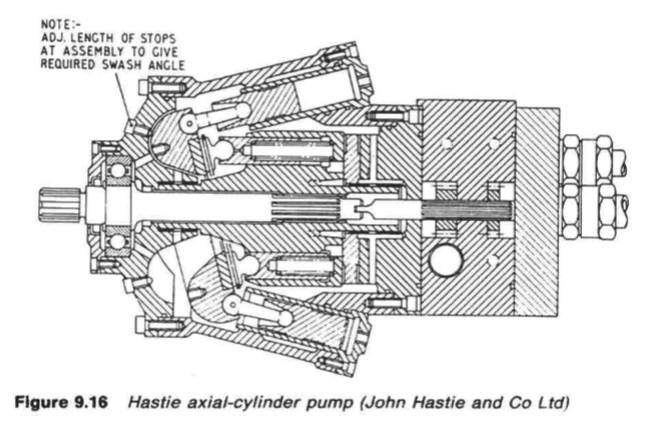

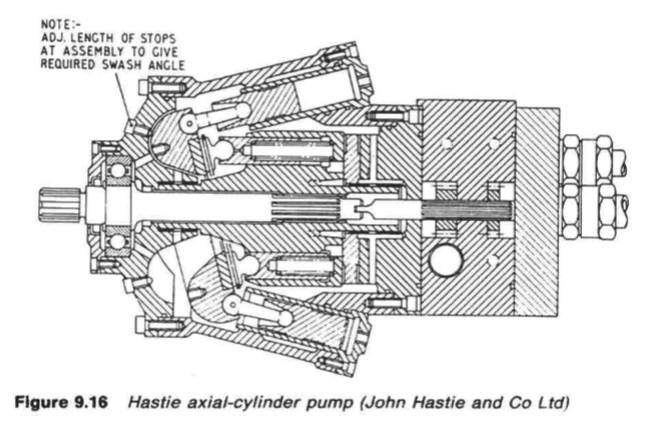

Variants of the servo-controlled swash plate axial cylinder pump (Figure below)

are capable of working at 210 bar. Each pump is complete with its own torque

motor, servo-valve, cut-off mechanism, shut-off valve and oil cooler. These

pumps are brought into operation as described earlier and an idle pump is

prevented from motoring.

Figure : Hastie axial-cylinder pump (John Hastie and Co Ltd)

The rotating assembly of the pump, which consists of cylinder, nine pistons,

valve plate, slippers, slipper plate and retaining ring, is manufactured from ENS

steel, which is finally machined, heat treated and then hardened for long wear.

The nine pistons are fitted with return springs. The casing and covers are of

nodular cast iron.

The main valve block is of ENS steel and houses five check

valves, main pump relief valve, boost and servo-relief valves, boost gear pump

and servo-gear pumps. Piping from the valve block supplies the servo pistons

via the servo valve. The main drive is through a splined shaft to the cylinder

body of the pump. The pump swash plate is actuated by two servo cylinders

which receive oil at the desired pressure through a directional servo-valve.

The

servo-valve is displaced initially by the torque motor acting on the input signal

demand and is returned to the neutral position by the hunting linkage

connected to the swash plate. The hunting action is achieved through the

application of a simple lever system connecting input and displacement

servo-valve and the hunting action from the pump swash plate angle. This

allows for a very fast response.

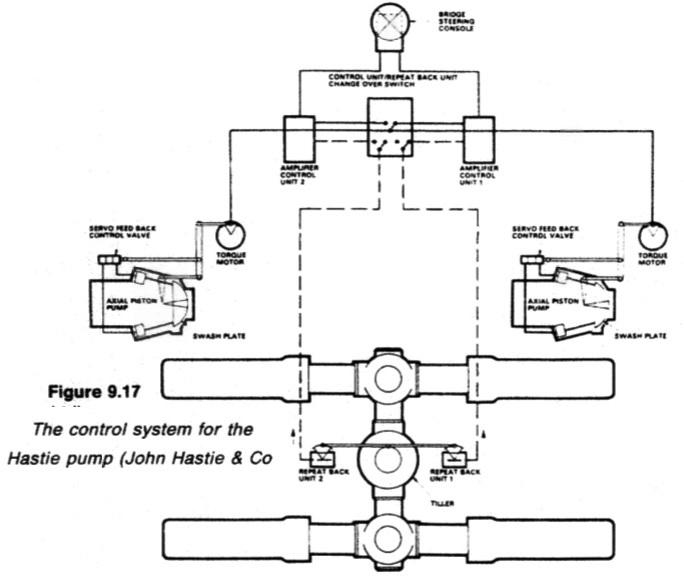

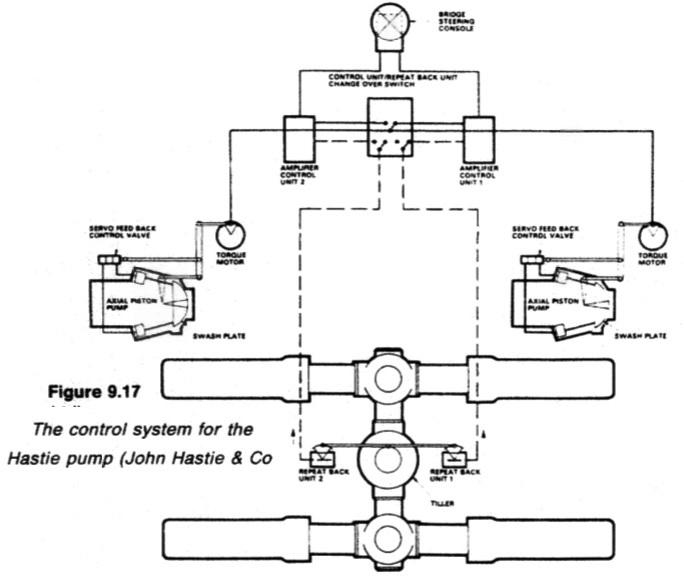

Figure : The control system for the Hastie pump (John Hastie & Co.

Ltd)

The control system is shown in Figure 9.17. As will be seen, a torque motor,

receiving the appropriate signal from the bridge through an amplifier unit

actuates the floating lever, putting the pumps on stroke in response. The

hunting action of the floating lever is no longer required as the normal control

of the steering gear from the bridge is by electric signal.

The signal is directed

to the torque motor which operates the servo valve that in turn controls the

pump. When the steering gear has attained the required rudder angle, the

electric feed back unit connected directly to the rudder-stock cancels the input

signal to the control amplifier, and the steering gear is held at that angle until

another rudder movement is required.

This form of control eliminates the need for mechanical linkage and hunting

gear on the steering gear.

Later modifications

The Amoco Cadiz disaster focused attention on the fact that failure of the

common hydraulic pipe system of a four ram steering gear with duplicated

power units, could result in rapid discharge of oil from the circuit and loss of

steering capability.

Four ram or double vane type gears with duplicated

hydraulic circuits, as well as duplication of pumps, were developed. This

arrangement cannot, however, be operated with both pumps running and the

duplicated hydraulic circuits isolated from each other. The systems have to be

connected in common for operation with both pumps. Either pump can provide

hydraulic power for the combined circuit or for an isolated half, with the bypass

open on the other part.

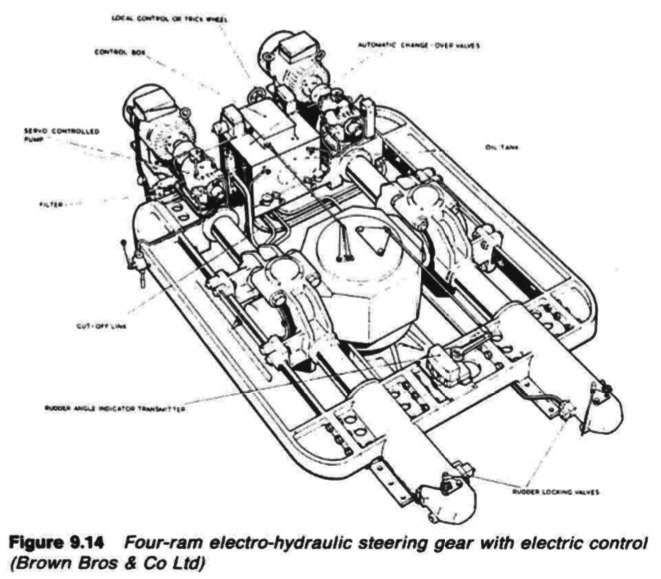

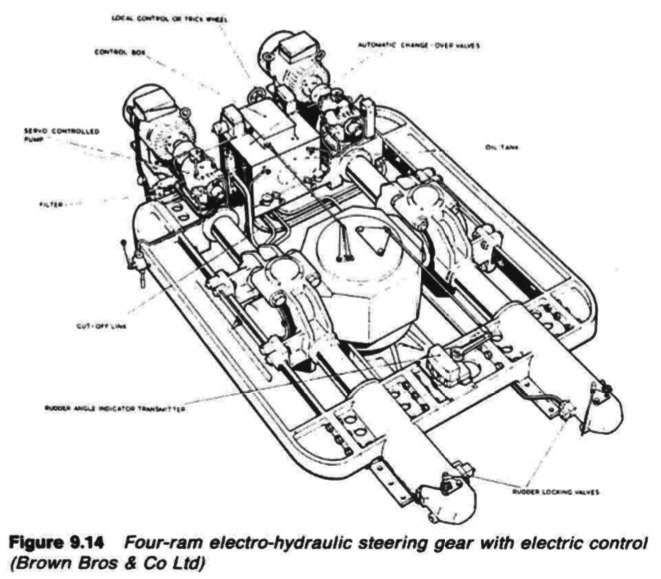

Figure : Four ram electro hydraulic steering gear with electric control

Figure above illustrates a four ram gear which complies with the International

Convention for the Safety of Life at Sea (SOLAS) regulations (1974, amended

1981) relating to tankers, chemical tankers or gas carriers of lOOOOgt and

upwards (see especially Chapter 11-1 Regulation 29, Paragraph 16).

Two main power and servo-power units draw from a two-compartment

tank fitted with oil level switches arranged at three levels. Level 1 gives an

initial alarm following loss of oil from either system. In normal operation one or

The Hastie-Brown split system, shown here in split operation,

is arranged to give two ram operation automatically in the event of loss of

fluid from one system both power units provide hydraulic power to all four rams. Continued loss of

oil initiates one or both of the level 2 switches. These energize their respective

solenoid operated servo valves, causing the combined isolating and bypass

valves to operate, splitting the system such that each power unit supplies two

rams only. At the same time if one power unit is stopped it is automatically

started.

Further loss of oil, and the system on which it is occurring will operate one of

the level 3 switches. This will close down the power units on the faulty side.

Steering then continues, uninterrupted but at half the designed maximum

torque on the sound system. The defective system is out of action and isolated.

Summarized below various ship steering gears general guideline:

- Ship Steering gear failures and safeguards

The hydraulic circuit incorporates an arrangement of stop and bypass valves in the chest VC, which enable the gear to be operated on all four or on any two adjacent cylinders but not with two diagonally disposed cylinders.

......

- Four-ram electro-hydraulic steering gear mechanism

The hydraulic circuit incorporates an arrangement of stop and bypass valves in the chest VC, which enable the gear to be operated on all four or on any two adjacent cylinders but not with two diagonally disposed cylinders.

......

- Enclosed hunting gear

The light construction of the combined control and hunting gears is possible

because the forces concerned are moderate. The self-contained unit is

self-lubricating, and contained in an oil-tight case.

......

- Ship steering control mechanism- use of Hydraulic telemotor

The telemotor has become, on many vessels, the stand-by steering control

mechanism, used only when the electric or automatic steering fails. It comprises

a transmitter on the bridge and a receiver connected to the steering gear

variable delivery pump, through the hunting gear.

......

- Two-ram electro-hydraulic steering gear with variable

delivery pumps

An arrangement of a two-ram steering gear with variable

delivery pumps may have a torque capacity of 120-650 kNm.

The cylinders for this gear are of cast steel but the rarns comprise a one-piece

steel forging with integral pins to transmit the movement through cod pieces

which slide in the jaws of a forked tiller end.

......

- Rudder carrier bearing & Steering gear

The rudder carrier bearing takes the weight of the rudder on a

grease lubricated thrust face. The rudder stock is located by the journal

beneath, also grease lubricated

......

- Small hand and power gears - Ship steering systems

A simpler variant of the electro-hydraulic gear, for small ships requiring rudder

torques below say, 150 kNm

......

- Four ram gear with servo-controlled axial cylinder pumps

Variants of the servo-controlled swash plate axial cylinder pump

are capable of working at 210 bar. Each pump is complete with its own torque

motor, servo-valve, cut-off mechanism, shut-off valve and oil cooler.

......

- Vane type gear - provides security of four ram steering gear

These may be regarded as equivalent to a two-ram gear, with torque capacities

depending on size. An assembly of two rotary vane gears, one above the other,

provides the security of a four ram gear.

......

- Details of two ram hydraulic steering gear arrangement

When the main pumps are at no-stroke, the auxiliary pumps dischar.

to the reservoir via a pressure-limiting valve PC20, set at 20 bar, and to t

pump casings. When the main pumps are on-stroke, the auxiliary pump

discharge to the main pump suction.

......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||