Home page||Steering gears ||

Principle of a Vane type gear which provides security of four ram steering gear

Vane type gear :

These may be regarded as equivalent to a two-ram gear, with torque capacities

depending on size. An assembly of two rotary vane gears, one above the other,

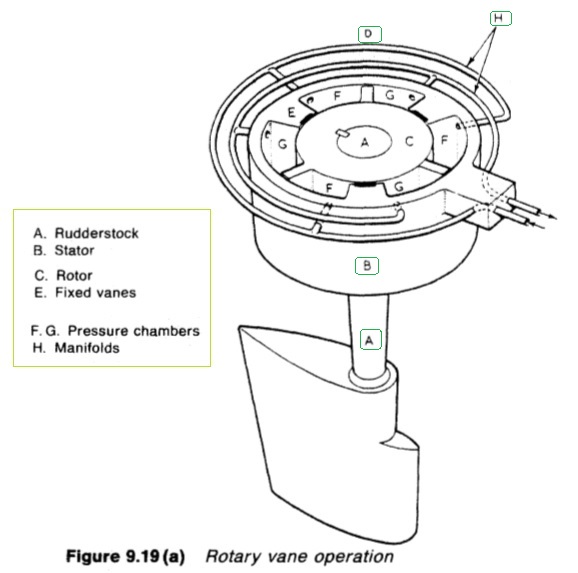

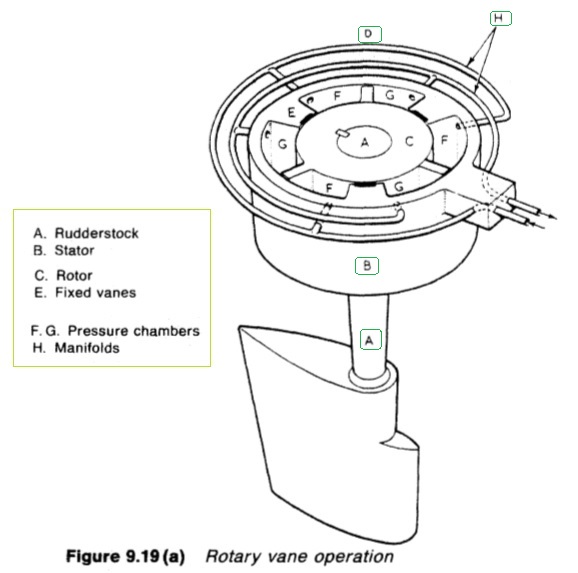

provides the security of a four ram gear. Figure 9.19 illustrates the principle.

The rotor C is fitted and keyed to a tapered rudder stock, the stator B is

secured to the ship's structure. Fixed vanes, secured equidistantly in the stator

bore and rotating vanes secured equidistantly in the rotor, form two sets of

pressure chambers in the annular space between the rotor and stator. They are

interconnected by a manifold. Fluid supplied at pressure to one set of these

chambers will rotate C clockwise and the rudder will turn to port, or to

starboard if the alternate set is put under pressure.

Three fixed and three moving vanes are usual and permit a total rudder angle

of 70', i.e. 35° in each direction. The movement obtainable from a gear with

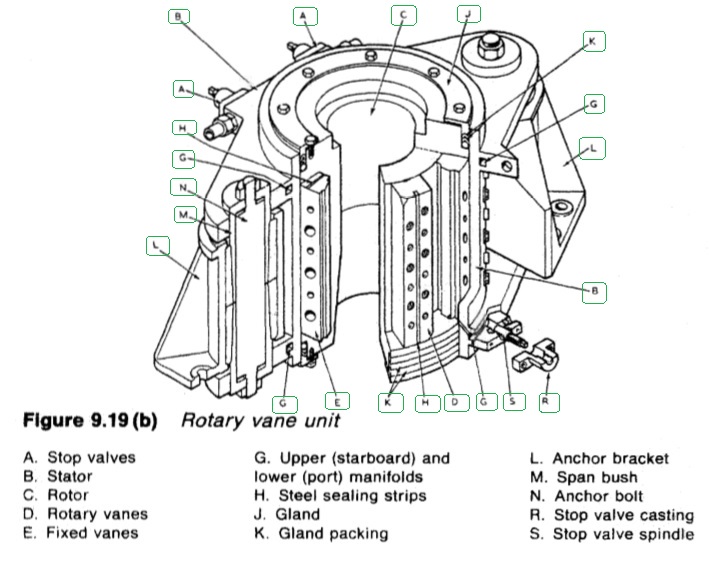

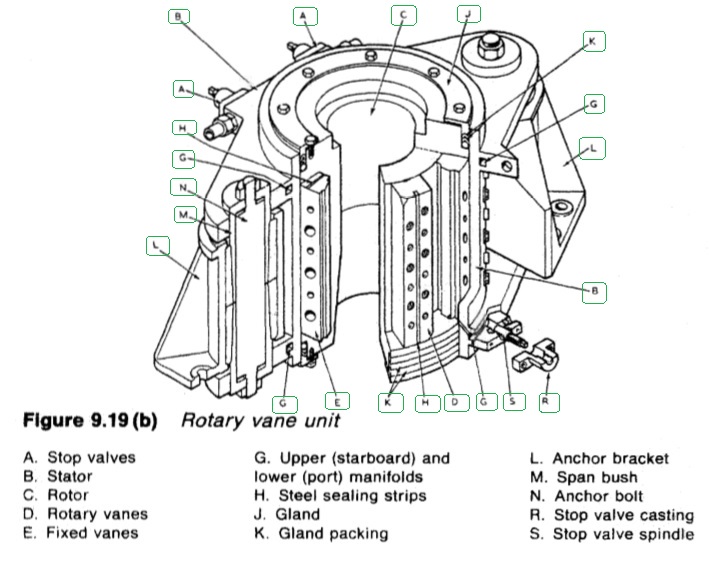

two fixed and two moving vanes, may be 130°. Figure 9.19 (b) shows the detail

of a typical unit.

Figure 9.19 (b): Rotary vane unit

The fixed and rotating vanes may be of spheroidal graphite cast iron. They

are securely fixed to the cast steel rotor and stator by high tensile steel dowel

pins and cap screws. Keys are also fitted along the length of the rotary vanes, for

mechanical strength. Assembly of the gear would not be possible if the fixed

vanes were keyed; they rely on the dowels to provide equivalent strength.

The

vanes fixing is considered to be of sufficient strength to make them suitable to

act as rudder stops. Steel sealing strips, backed by synthetic rubber, are fitted in

grooves along the working faces of the fixed and rotary vanes, thus ensuring a

high volumetric efficiency, of 96—98% even at the relief valve pressure of

100 bar or over. Rotation of B is prevented by means of two anchor brackets,

and two anchor pins. The anchor brackets are securely bolted to the ship.

Vertical clearance is arranged between the inside of the stator flanges and the

top and bottom of the anchor brackets to allow for vertical movement of the

rudderstock. This clearance varies with each size of the rotary vane unit, but is

approximately 38 mm in total and it is necessary that the rudder carrier should

be capable of restricting the vertical movements of the rudderstock to less than

this amount.

The method of control for these gears and also for the hydraulic supply

system is as described for electro-hydraulic gears.

Figure 9.19 (a): Rotary vane operation

Summarized below various ship steering gears general guideline:

- Ship Steering gear failures and safeguards

The hydraulic circuit incorporates an arrangement of stop and bypass valves in the chest VC, which enable the gear to be operated on all four or on any two adjacent cylinders but not with two diagonally disposed cylinders.

......

- Four-ram electro-hydraulic steering gear mechanism

The hydraulic circuit incorporates an arrangement of stop and bypass valves in the chest VC, which enable the gear to be operated on all four or on any two adjacent cylinders but not with two diagonally disposed cylinders.

......

- Enclosed hunting gear

The light construction of the combined control and hunting gears is possible

because the forces concerned are moderate. The self-contained unit is

self-lubricating, and contained in an oil-tight case.

......

- Ship steering control mechanism- use of Hydraulic telemotor

The telemotor has become, on many vessels, the stand-by steering control

mechanism, used only when the electric or automatic steering fails. It comprises

a transmitter on the bridge and a receiver connected to the steering gear

variable delivery pump, through the hunting gear.

......

- Two-ram electro-hydraulic steering gear with variable

delivery pumps

An arrangement of a two-ram steering gear with variable

delivery pumps may have a torque capacity of 120-650 kNm.

The cylinders for this gear are of cast steel but the rarns comprise a one-piece

steel forging with integral pins to transmit the movement through cod pieces

which slide in the jaws of a forked tiller end.

......

- Rudder carrier bearing & Steering gear

The rudder carrier bearing takes the weight of the rudder on a

grease lubricated thrust face. The rudder stock is located by the journal

beneath, also grease lubricated

......

- Small hand and power gears - Ship steering systems

A simpler variant of the electro-hydraulic gear, for small ships requiring rudder

torques below say, 150 kNm

......

- Four ram gear with servo-controlled axial cylinder pumps

Variants of the servo-controlled swash plate axial cylinder pump

are capable of working at 210 bar. Each pump is complete with its own torque

motor, servo-valve, cut-off mechanism, shut-off valve and oil cooler.

......

- Vane type gear - provides security of four ram steering gear

These may be regarded as equivalent to a two-ram gear, with torque capacities

depending on size. An assembly of two rotary vane gears, one above the other,

provides the security of a four ram gear.

......

- Details of two ram hydraulic steering gear arrangement

When the main pumps are at no-stroke, the auxiliary pumps dischar.

to the reservoir via a pressure-limiting valve PC20, set at 20 bar, and to t

pump casings. When the main pumps are on-stroke, the auxiliary pump

discharge to the main pump suction.

......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||