Home page||Valves & pipelines ||

Strainers & filters for ship service sytems

The term strainer is sometimes used specifically for a simple device made up with a single layer of coarse gauze, a very coarse wire mesh or a drilled or perforated plate. The strainer in this sense is installed to hold large foreign objects which could cause damage or blockage. The term filters also describes a device designed to prevent the passage of unwanted solids into or further along a system, but the implication is that the particles are very small and the filter cartridge or element has a more complex or elaborate make up.

The simplest strainer consists of a box with a removable lid in which a flat perforated plate is inserted such that the fluid must pass through the perforations. Such strainers are found in bilge systems immediately before bilge valves.

Perforation sizes vary according to duty and manufacture but are usually in the range 3-12 mm. Strainer plates corrode and erode and when cleaning due attention should be paid to the condition of the plate. If a gap has formed at the top or bottom of the plate (so that solid objects or rags could pass through) or if it is in danger of breaking up then it should be renewed. These strainers protect the pump. If strainer covers are hinged the hinges are made loose to avoid the problem of poor seating.

The state of the gasket should be checked, mating surfaces must be clean and care should be taken when closing the cover. Since these covers are frequently of cast iron and are secured by lugs and thumb screws care must be taken not to use undue force when closing them.

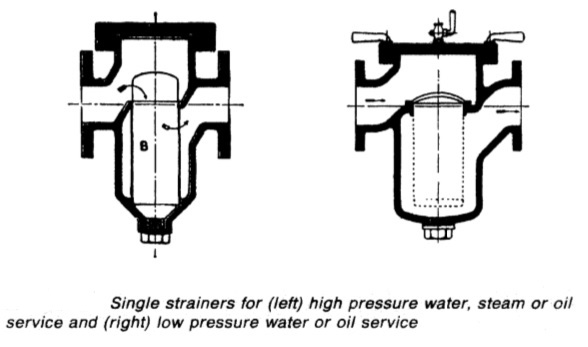

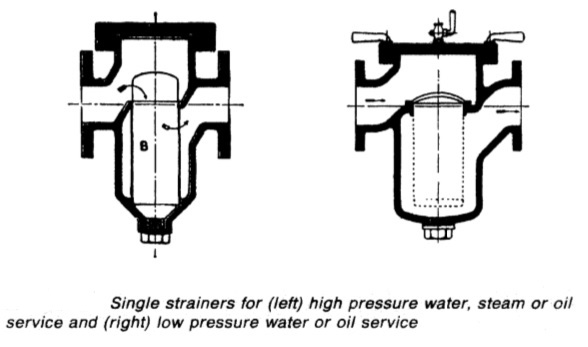

For high pressure water, steam or oil services simple basket strainers are used. These consist of a cylindrical container in which a perforated metal or wire basket is suspended (shown left Figure 1). Flow through these units is from the top, into the basket and out from the outside of the basket. They may be installed as duplex units with three way cocks at inlet and outlet so that one or both baskets can be in use, but one can be shut down for cleaning.

Close to

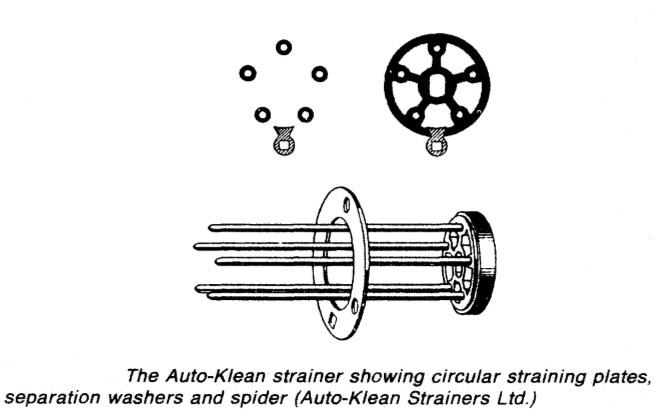

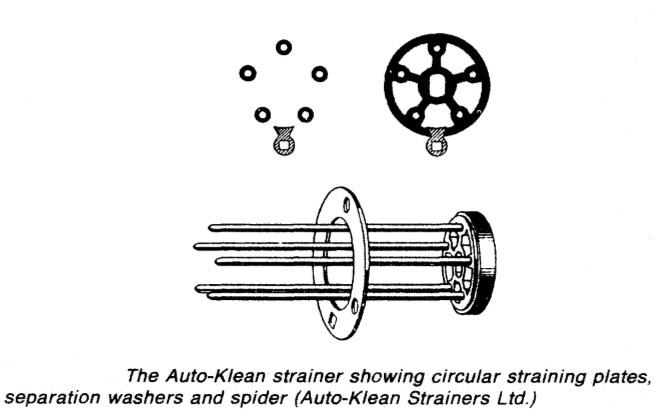

sea-water suction valves, similar basket strainers (shown right in Figure 1) having air release cocks, are installed. Lubricating oil systems are fitted with a wide variety of strainers some of which can be cleaned in situ. The knife edge strainer, (Figure 2) has a series of discs ganged to a shaft. Interspaced between the discs are a number of thin ringers. The solid particles are trapped on the edges of, and between, the discs.

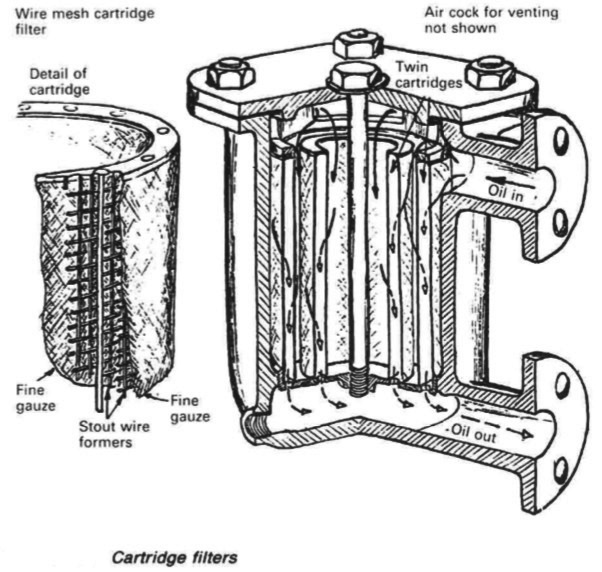

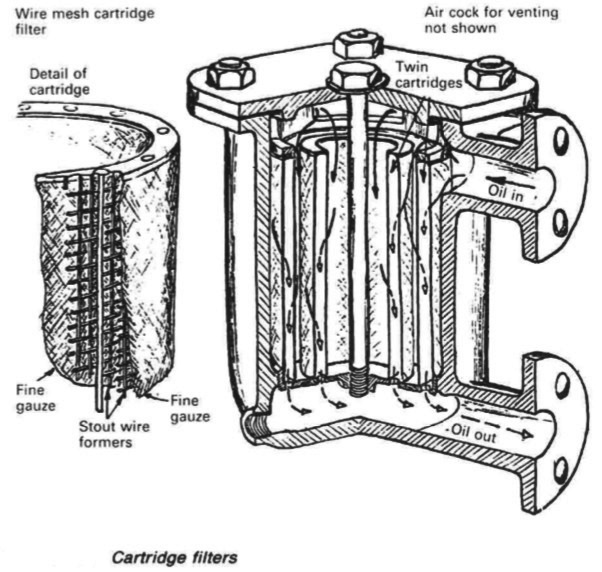

By rotating the disc shaft the particles are cleared by the fingers and fall to a sump, which is drained periodically. It is essential to operate these strainers regularly to prevent clogging when rotation may be difficult. Some have been fitted with electric motors for continuous operation. Cartridge filters (Figure 3) are usually of the duplex type and have various types of element. Some cartridges can be removed for cleaning; others

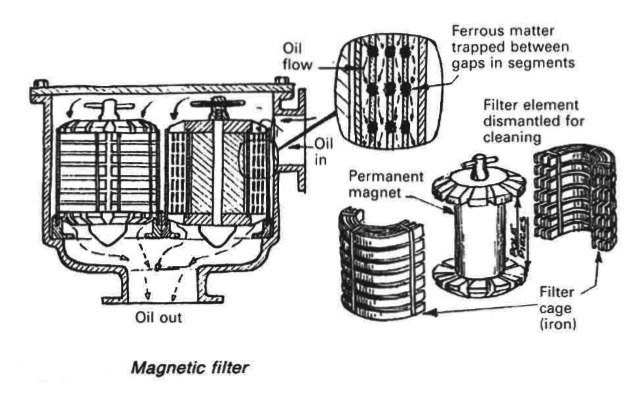

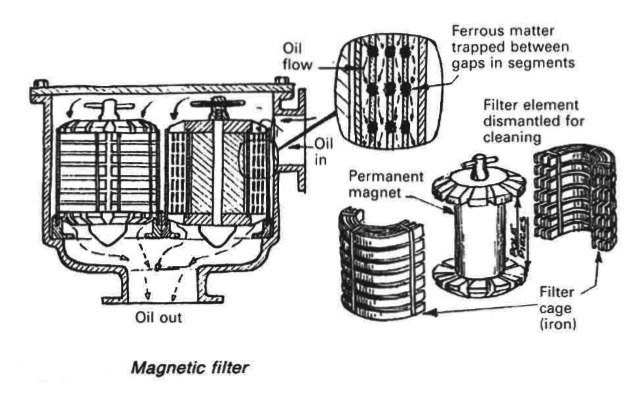

have renewable elements. Cartridges can be of gauze layers with different mesh sizes others are made up with layers of mesh and felt, some use membrane type materials. Magnetic filters (Figure 4) provide extra protection for engines and gearboxes where iron or steel wear particles are likely to be present.

Figure 1: Single strainers for (left) high pressure water, steam or oil service and (right) low pressure water or oil service

Figure 2: The Auto-Klean strainer showing circular straining plates, separation washers and spider (Auto-Klean Strainers Ltd.)

Figure 3: Cartridge filters

Figure 4: Magnetic filter

Summarized below some of the basic procedure of machinery valves & pipeline systems :

- Valves & pipeline materials corrosion & erosion

Galvanic corrosion is a major challenge for any pipes which carry sea water. Rust is a particular corrosion problem for steel pipes exposed to contact with sea water or moisture generally and air. Pipe runs along tank tops or on deck, are examples of the latter. Steel pipes in these areas require external as well as internal protection.....

- valves-&-pipelines-strength-of-materials

The strength of materials used for pipes and fittings must be adequate for the

system pressures and possible over-pressures. Pipelines and valves, for

example, used to carry and control the flow of high temperature, high pressure

steam must obviously be made to very exacting specifications by approved

manufacturers.....

- Valves & pipelines-system cleaning & draining

It is often found, in new ships, that the bilges and bilge systems have not been

thoroughly cleaned with the result that wood, nuts, bolts, rags and other debris

are found inside valves and pipes after initial bilge pumping. These choke the

valve-chests and prevent the valves from being properly closed. They also

block strainers. ....

- Expansion arrangements

Provision must be made in pipe systems to accommodate changes in length due to change of temperature, and so prevent undue stress or distortion as pipes expand or contract.....

- Valves & cocks

Cocks and valves are designed to control or interrupt flow. This is done in cocks by rotating the plug, and in valves by lowering, raising or rotating a disc in relation to a seating surface or by controlling the movement of a ball. ...

- Butterfly valves

A butterfly valve consists basically of a disc pivoted across the bore of a ring body having the same radial dimensions as the pipe in which it is fitted.....

- Gate valves

Unlike the globe valve, gate (or sluice) valves give full bore flow without change of direction. The valve disc known appropriately as a gate,....

- Globe valves

The globe valve has a bulbous body, housing a valve seat and screw down plug or disc arranged at right angles to the axis of the pipe....

- Relief valves

Excess pressure is eased by a relief valve . This consists of a disc held closed by a spring loaded stem. The compression on the spring can be adjusted so that the valve opens at the desired pressure. ....

- Valves traps

A steam trap is a special type of valve which prevents the passage of steam but allows condensate through. It works automatically and is used in steam heating lines to drain condensate without passing any steam. ....

- Flap valves & valve chest

Scupper pipes from accommodation spaces are fitted with non-return valves. Those scuppers from spaces below the bulkhead deck, are required to be fitted with non-return valves which can be positively closed from above the bulkhead deck or, if this is not practical, with two non-return valves.....

- Quick closingvalves

Fuel oil service and some other tanks must be fitted with valves that can be closed rapidly and remotely in the event of an emergency such as fire. Wire operated valves are commonly fitted,....

- Strainers & filters

The term strainer is sometimes used specifically for a simple device made up with a single layer of coarse gauze, a very coarse wire mesh or a drilled or perforated plate. ...

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||