Home page||Valves & pipelines ||

Expansion arrangements for Ships pipes and piping materials

Expansion arrangements:

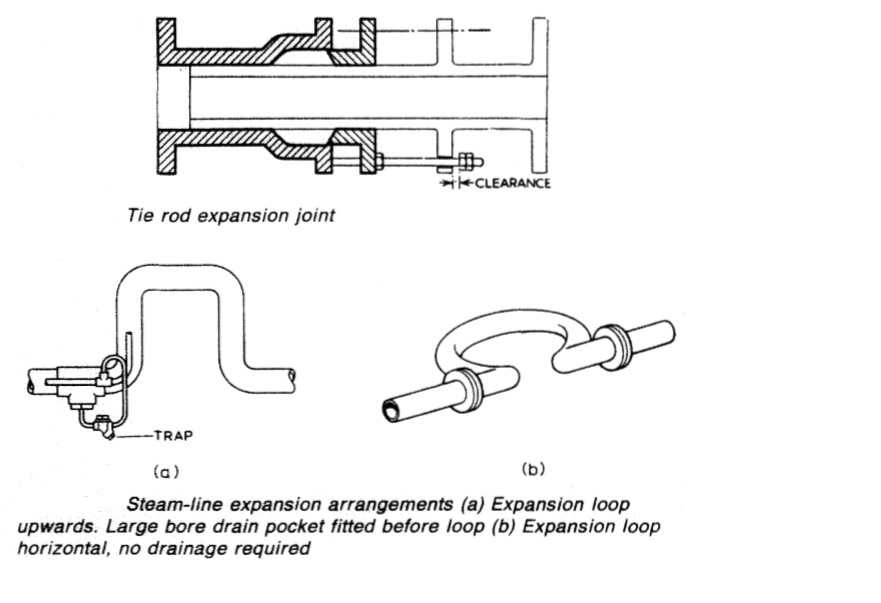

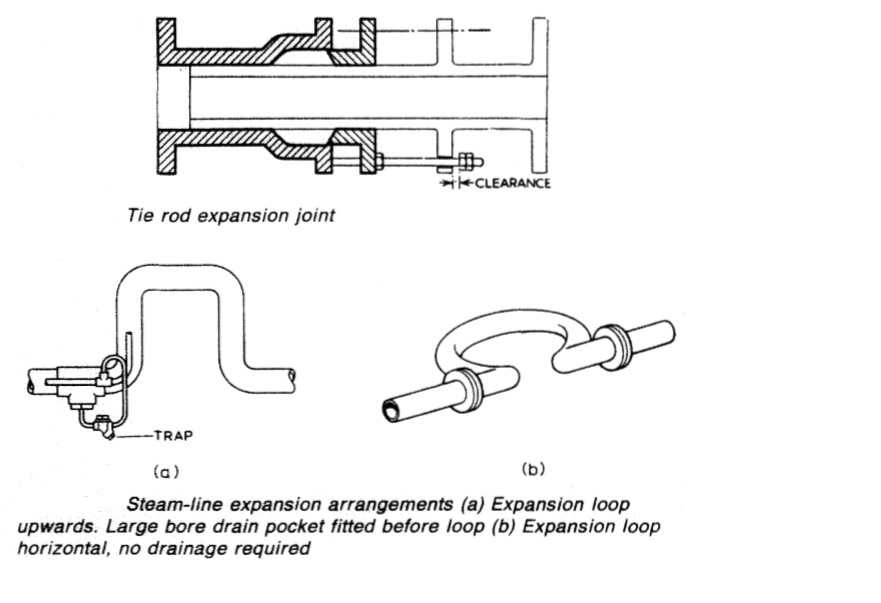

Provision must be made in pipe systems to accommodate changes in length due to change of temperature, and so prevent undue stress or distortion as pipes expand or contract. One type of expansion joint (Figure 3) has an anchored sleeve with a stuffing box and gland in which an extension of the joining pipe can slide freely within imposed limits.

Figure 1 & 2 :Tie rod expansion joint ;Steam-line expansion arrangements (a) Expansion loop upwards. Large bore drain pocket fitted before loop (b) Expansion loop horizontal, no drainage required

Simpler schemes (Figure 2a and 2b) allow for change of length with a right angle bend arrangement or a loop. For high pressures and temperatures with associated greater pipe diameter and thickness other methods may be more appropriate.

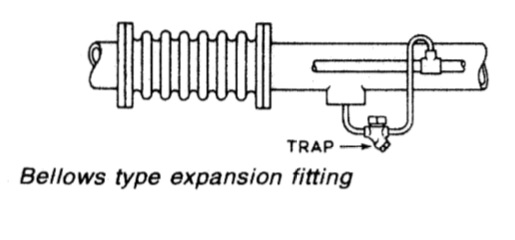

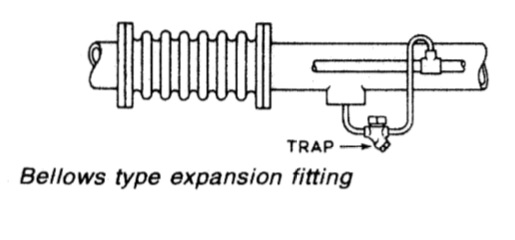

Fig 3:Bellows type expansion fitting

Stainless steel bellows expansion joints (Figure 3) are commonly used since they will absorb some movement or vibration in several planes, eliminate maintenance, reduce friction and heat losses. Maximum and minimum working temperatures must be considered when choosing a bellows piece, which must be so installed that it is neither over-compressed nor over-extended. Its length must be correct for the temperature change. Stainless steel is the usual material for temperatures up to 500 deg C. Beyond that and for severe corrosive conditions, other materials are required. Normally the bellows has an internal sleeve, to give smooth flow, to act as a heat shield and to prevent erosion. If exposed to the possibility of external damage, it should have a cover.

In usual marine applications, bellows joints are designed and fitted to accommodate straight-line axial movement only and the associated piping requires adequate anchors and guides to prevent misalignment. It will be apparent that, in certain cases, the end connections will act adequately as anchors and that well designed hangers will be effective guides.

An axial bellows expansion joint can accommodate compression and extension, usually stated as plus or minus X mm, i.e. it will compress or extend X mm from the free length, at which it is supplied. It is most important that the unit be installed at its correct length as extension or compression outside its specified limits will cause premature fatigue.

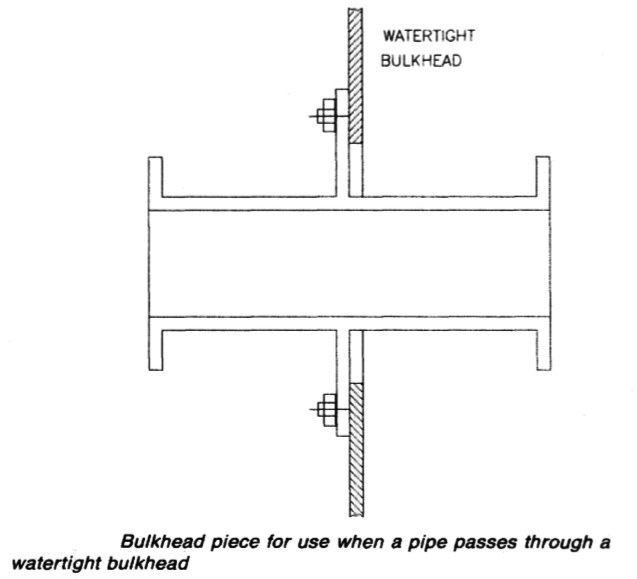

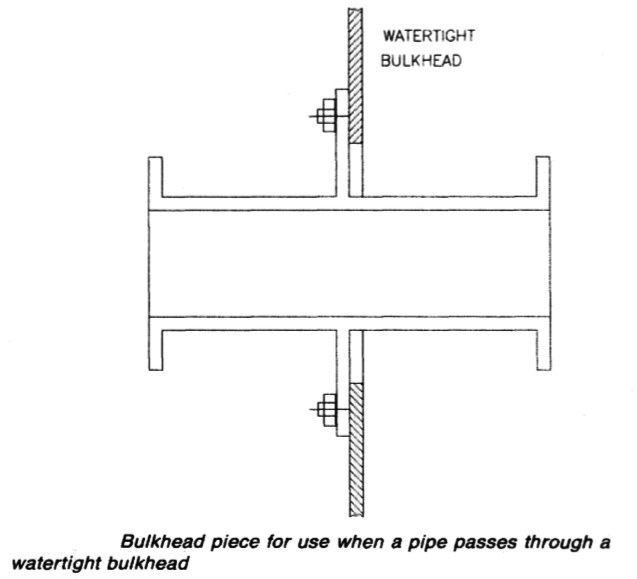

Fig 4 :Bulkhead piece for use when a pipe passes through a watertight bulkhead

Watertight bulkheads

Pipes are carried through watertight bulkheads with the use of special fittings (Figure 4) to avoid impairment of their integrity. The large flange of the fitting, covers the necessary clearance in the bulkhead.

Joints

Joints between flanges should be impervious to damage from the fluids carried and a variety of materials are available to suit the different requirements. Rubber for example, with or without cotton insertion, is suitable for water but not for oil. High pressure can force a joint out of a flange so that the thinnest joints are used for the highest pressures. Some jointing fabrics are sheathed with copper or stainless steel, which may be grooved finely and lightly in the

area adjacent to the pipe bore.

Most materials deteriorate with time and temperature so that periodic replacement may be necessary. Graphite compounds assist flexibility. Mating flanges should be parallel and accurately machined. Bolts should fit reasonably well and have good threads.

Summarized below some of the basic procedure of machinery valves & pipeline systems :

- Valves & pipeline materials corrosion & erosion

Galvanic corrosion is a major challenge for any pipes which carry sea water. Rust is a particular corrosion problem for steel pipes exposed to contact with sea water or moisture generally and air. Pipe runs along tank tops or on deck, are examples of the latter. Steel pipes in these areas require external as well as internal protection.....

- valves-&-pipelines-strength-of-materials

The strength of materials used for pipes and fittings must be adequate for the

system pressures and possible over-pressures. Pipelines and valves, for

example, used to carry and control the flow of high temperature, high pressure

steam must obviously be made to very exacting specifications by approved

manufacturers.....

- Valves & pipelines-system cleaning & draining

It is often found, in new ships, that the bilges and bilge systems have not been

thoroughly cleaned with the result that wood, nuts, bolts, rags and other debris

are found inside valves and pipes after initial bilge pumping. These choke the

valve-chests and prevent the valves from being properly closed. They also

block strainers. ....

- Expansion arrangements

Provision must be made in pipe systems to accommodate changes in length due to change of temperature, and so prevent undue stress or distortion as pipes expand or contract.....

- Valves & cocks

Cocks and valves are designed to control or interrupt flow. This is done in cocks by rotating the plug, and in valves by lowering, raising or rotating a disc in relation to a seating surface or by controlling the movement of a ball. ...

- Butterfly valves

A butterfly valve consists basically of a disc pivoted across the bore of a ring body having the same radial dimensions as the pipe in which it is fitted.....

- Gate valves

Unlike the globe valve, gate (or sluice) valves give full bore flow without change of direction. The valve disc known appropriately as a gate,....

- Globe valves

The globe valve has a bulbous body, housing a valve seat and screw down plug or disc arranged at right angles to the axis of the pipe....

- Relief valves

Excess pressure is eased by a relief valve . This consists of a disc held closed by a spring loaded stem. The compression on the spring can be adjusted so that the valve opens at the desired pressure. ....

- Valves traps

A steam trap is a special type of valve which prevents the passage of steam but allows condensate through. It works automatically and is used in steam heating lines to drain condensate without passing any steam. ....

- Flap valves & valve chest

Scupper pipes from accommodation spaces are fitted with non-return valves. Those scuppers from spaces below the bulkhead deck, are required to be fitted with non-return valves which can be positively closed from above the bulkhead deck or, if this is not practical, with two non-return valves.....

- Quick closingvalves

Fuel oil service and some other tanks must be fitted with valves that can be closed rapidly and remotely in the event of an emergency such as fire. Wire operated valves are commonly fitted,....

- Strainers & filters

The term strainer is sometimes used specifically for a simple device made up with a single layer of coarse gauze, a very coarse wire mesh or a drilled or perforated plate. ...

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||