Home page||Auxiliary Power ||

Ship Auxiliary engine common fuel injector

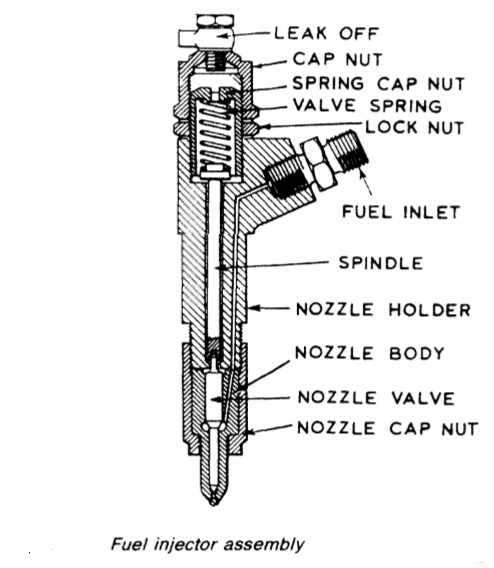

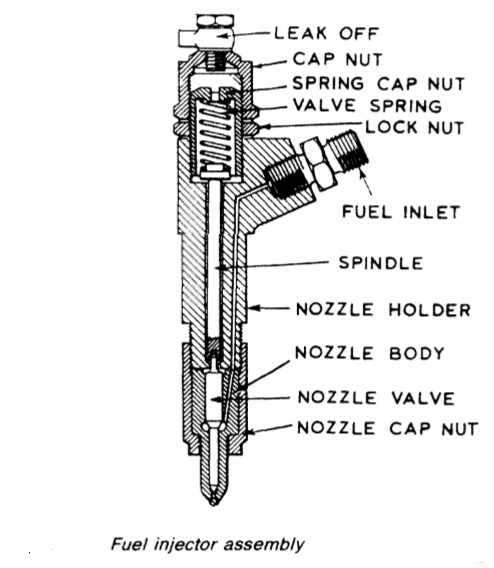

The fuel injector nozzle contains a non-return valve labelled nozzle valve in the

drawing (Figure 1), which is forced open against the spring loading by

pressure of fuel from the fuel pump. The upper part of the nozzle (or needle)

valve is lapped into the nozzle body within which it works freely. The lower

part is of smaller diameter having at its extremity a valve face and at the

junction of the two diameters a shoulder. The upper end has a small extension

or spigot which engages with the valve spindle.

Fuel is delivered to an annular space in the nozzle via a hole, drilled through

the nozzle body from the inlet. The nozzle valve is forced from its seat in the

nozzle body by the pressure of fuel from the pump, acting on the shoulder of

the needle valve. Pressure from the fuel pump also forces the fuel through the

holes in the nozzle to form a fine spray in the engine combustion chamber.

Figure 1 : Fuel injector assembly

When fuel pump delivery ceases, there should be a sharp drop in pressure

which means that the nozzle valve will close smartly with an instant

interruption of flow.

Injector nozzles normally require cooling when residual fuel is used.

Interruption of the fuel valve cooling supply, quickly results in vapour lock of

the cooling passages within the nozzles and then blockage by scale. When fuel

valve cooling is restored after a failure, it is essential to check flow from all

returns, and to clear any with no return flow immediately. Loss of cooling will

result in the formation of carbon deposits (trumpets) around the nozzles in a

very short time.

Injectors should be taken out for examination, external cleaning and testing

at regular intervals based on running hours as recommended by the makers

handbook or as dictated by operational factors. Injector opening pressure,

spray pattern and effective closing without leakage, are checked with a test

pump. Defective injectors require overhaul in very clean conditions with

special tools.

On board overhaul may be carried out or alternatively nozzles

may be sent to a specialist firm. After a replacement nozzle has been fitted in the

nozzle holder, injector spring compression is set on the test rig and then the

spray pattern and effective closing are checked.

Inexperienced personnel must be warned against contact with the nozzle tip when

testing. Spray intensity is sufficient to puncture the skin and inject fuel.

For cleaning the fuel injectors, a special set of tools is available and contains

the following main items: brass wire brush, nozzle body groove scraper,

probing tool nozzle body seat cleaner, nozzle body dome cavity cleaner.

Summarized below some of the basic procedure of marine auxiliary machinery :

- Auxiliary engine general construction

Major problems have been experienced on large slow-speed

engines with some of the poor quality bunkers such as those containing

catalytic fines. Fuel should conform to the specification given in the instruction

book for the engine.

......

- Auxiliary engine back pressure turbine

Many ships have used an auxiliary steam turbine as a primary pressure reducing stage before passing the steam to other auxiliaries demanding steam at a substantially lower pressure than that available. Such an arrangement gives a heat balance which is far more favourable than that obtained with a pressure reducing valve......

- Auxiliary engine fuel pump

The most common fuel pump used on auxiliary diesel engines is the Bosch

type. This is a cam operated jerk pump with a helical groove on the plunger to

control the fuel cut-off and therefore the quantity of fuel delivered to the

cylinder for combustion.

......

- Auxiliary engine common fuel injector

Fuel is delivered to an annular space in the nozzle via a hole, drilled through

the nozzle body from the inlet. The nozzle valve is forced from its seat in the

nozzle body by the pressure of fuel from the pump, acting on the shoulder of

the needle valve.

......

- Auxiliary engine cooling system

A variety of cooling systems may be adopted for marine auxiliary engines but

the most commonly used is the simple closed circuit system . Sea

water is passed through the intercooler, the oil cooler and then the jacket water

cooler in series flow.

......

- Auxiliary engine hydraulic governor

When used for alternating current power generation, a diesel engine is normally fitted with a hydraulic governor. This incorporates a centrifugal speed sensing device (spring loaded flyweights) controlling a suitably damped oil operated servo-cylinder through a pilot valve.

......

- Auxiliary engine speed governing system

Unlike propulsion turbines, generator turbines work at constant speed and must be governed accordingly. Classification Society rules require that there must be only a 10% momentary and a 6% permanent variation in speed when full load is suddenly taken off or put on.

......

- Auxiliary engine tracing faults

The failure of an engine to start or problems while running may be traced to

faults with the fuel injection system or other possible causes. Instruction

manual guidance on fault finding and remedies will include some of the typical

problems

......

- Generators driven from the main propulsion

Generators can variously be driven from the propeller shaft, through a gearbox or by being mounted on the engine itself.

......

- Exhaust gas boilers

The original exhaust gas boilers or economizers were of simple construction and produced, from the low powered engines of the time, a very moderate amount of steam. As large slow speed engine powers increased, the larger quantity of steam that could be generated from otherwise wasted exhaust energy,

......

- Auxiliary engine Turbo generator construction

Turbo-generator construction-For electrical power generation, turbines are conventionally horizontal axial flow machines of the impulse reaction type. They may exhaust either to an integral condenser (invariably underslung) or to a separate central auxiliary condenser or the ship's main condenser.

......

- Caterpillar engine fuel system

The range of larger Caterpillar engines use helix-type fuel pumps driven from a

separate camshaft.......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||