Home page||Auxiliary Power ||

Marine auxiliary diesel engine general construction

Over recent years, many owners have elected to burn low grade residual fuels

in medium-speed auxiliary engines, sometimes with disastrous results. Fuels

bunkered for slow-speed main engines may be of too poor a quality for use in

auxiliaries even where the engines have been designed for heavy fuel

operation.

Major problems have been experienced on large slow-speed

engines with some of the poor quality bunkers such as those containing

catalytic fines. Fuel should conform to the specification given in the instruction

book for the engine.

Typical of the medium-speed engines designed to be capable of running on

heavy fuel are the Allen S12 series in-line engines having four, six, eight

designated VS12 which are produced with twelve or sixteen cylinders.

General construction (based on the Allen S12 engine)

The in-line S12 engine structure (Figure 7.1) is based on a deep section cast iron

bedplate and a cast iron A-frame of monobloc construction which are flanged

and bolted together. The bedplate carries thin wall, steel-backed, white-metal

or aluminium-tin lined main bearings.

An additional bearing is incorporated to

carry the combined loads of the flywheel and part of the weight of the

generator. Access doors are provided at the front and back. Those on the back

of the engine are fitted with crankcase explosion relief valves.

In this style of construction, which is common to many medium-speed

engines, it is necessary to lift the A-frame if the crankshaft is to be removed.

Some designs incorporate a C-frame arrangement which permits side removal

of the crankshaft.

The one-piece alloy steel crankshaft is slab-forged, oil-hardened and

tempered. A solid half coupling forged integrally carries the flywheel to which

the generator is coupled. The main coupling bolts pass through the crankshaft

half coupling, the flywheel and the generator half coupling; two additional

bolts are incorporated to retain the flywheel on the crankshaft when the

generator is uncoupled.

Additional machines such as an air compressor or a

bilge pump may be driven from the free end of the crankshaft, through a clutch.

Axial location of the crankshaft is maintained by renewable thrust rings. Drilled

passages in the crankshaft feed oil from the main to the connecting rod

bearings. In the S12-F engine these oil passages are arranged to provide a

continuous supply of oil to the cooled pistons. Where necessary, balance

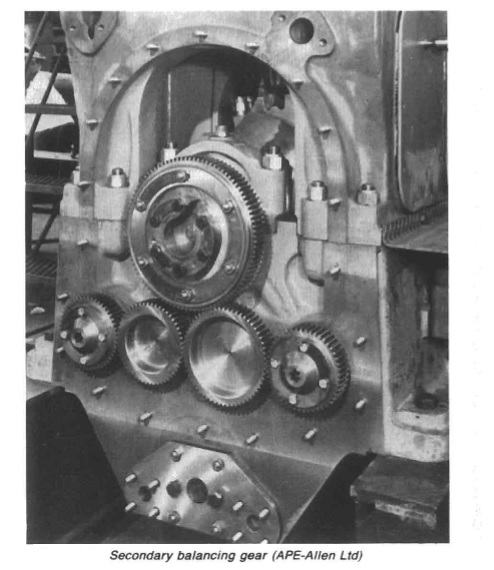

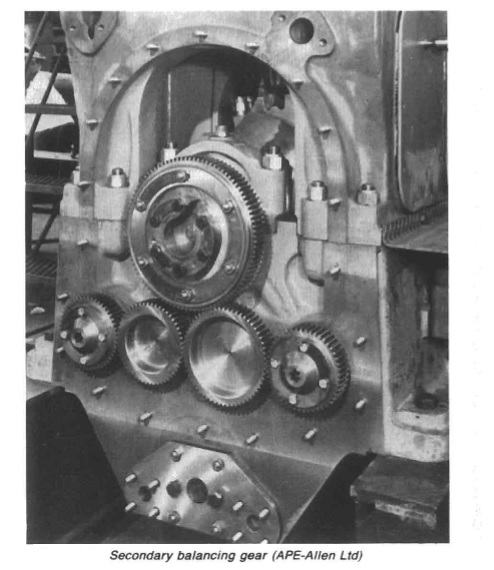

weights are bolted to the crank-webs. In four-cylinder engines having cranks at

180°, secondary balancing gear is required (Figure 7.2).

Figure 7,1 Six cylinder S12-F engine (APE-Allen Ltd)

Figure 7,2 Secondary balancing gear (APE-Allen Ltd)

The connecting rods are H-section steel forgings, bored to carry oil to the

gudgeon pin bush, which is a light interference fit in the rod. Crankpin bearings

are thin-walled steel, lined with aluminium-tin, split horizontally and secured

by four fitted bolts. Connecting rods of differing designs will be found in some

engines. Thus the bottom end assembly for the Allen VS12 (vee engine) series

(Figure 7.3) is made simple by axially displacing both banks of cylinders and

having two connecting rod bottom end bearings on each crankpin.

The large

end bearing is split diagonally to enable the connecting rod to be withdrawn

through the cylinder. Bearing butts are serrated for location. Bronze bushes are

used for the top ends; the large ends have steel backed, aluminium-tin bearings

with an overlay which is deposited by plating.

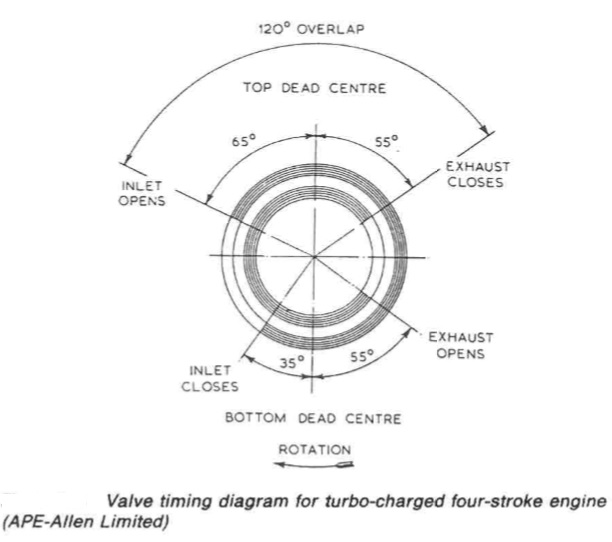

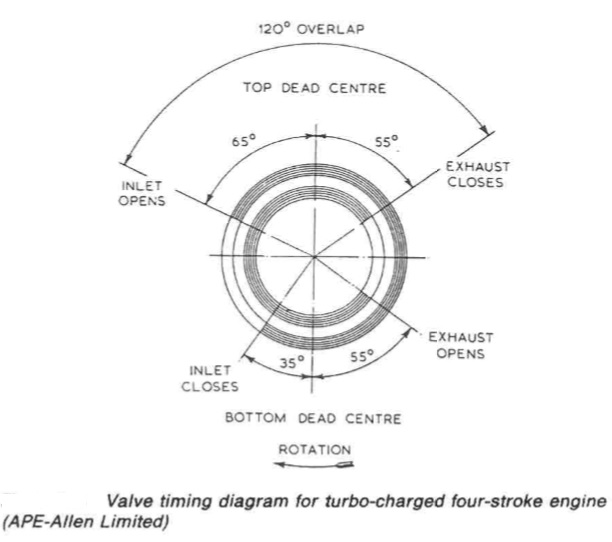

Figure 7.3 Valve timing diagram for turbo charged four stroke engine

(APE-Atlen Limited)

The fully-floating gudgeon pin of the Allen S12 is steel, case-hardened and

ground, retained in the aluminium alloy piston by circlips. The piston has an

integrally cast alloy iron carrier for the top piston ring, two additional pressure

rings and one slotted oil scraper ring, all above the gudgeon pin. Pistons for the

S12-F are one-piece aluminium-alloy castings incorporating oil cooling

cavities.

The oil provides intensive cooling of the piston particularly in the

region of the ring belt. The wet-type close grained, cast iron cylinder liners, are

supported by a flange at the top which is sandwiched between the cylinder

head and a spigot with ring gasket, on the engine frame. To permit vertical

expansion of the liner it is free to move at its lower end, a seal being effected by

two synthetic compound O rings carried in grooves in the liner wall

Camshaft and cylinder head

The camshaft, is driven by a roller chain (some engines have a gear train). To

allow accurate phasing of crankshaft and camshaft during initial set up and if

timing has to be reset, elongated holes are provided at the coupling between

the camshaft drive wheel and the camshaft. Adjustable packing pieces inserted

into the elongated holes ensure that correct timing is maintained.

Lubrication of the camshaft bearings is by a forced feed system; an oiiway

bored through the full length of the camshaft conducting the oil to the

bearings. An extension of the camshaft at the driving end, is provided with a

flexible coupling for the hydraulic governor and tachometer drive.

The individual alloy cast iron cylinder heads have totally enclosed valve

gear which is lubricated from the engine oil system. The S12-D engine has one

inlet and one exhaust valve, the S12-F, because of its higher running speed, is

fitted with heads having two inlet and two exhaust valves.

The valve pairs are

parallel and operated by rocking levers and guided bridges. Each valve has two

springs and Is fitted with a rotator. The valves seat in the cylinder heads on

renewable inserts of iron alloy. The centrally placed fuel injector is situated

between the valve covers so that fuel oil contamination of lubricating oil is

avoided. This also enables the injectors to be withdrawn for servicing without

disturbing the valve covers.

Fuel pump and timing diagrams

Separate camshaft-actuated helix-type fuel pumps are employed for each

cylinder. These deliver fuel to the injectors which are set to lift at a pressure of

176 kg/cm2 on the S12-D and 211 kg/cm2 on the S12-F, Fuel pump delivery

volume is controlled by a rack which alters the cut-off or spill point. The racks

are linked through a control shaft to the engine governor which thus regulates

the end of the fuel delivery period and hence the quantity of fuel delivered

according to the power required. Fuel injection commences at approximately

15° before top-dead-centre and takes place over a period of about 35° of crank

angle. Combustion should be completed within this period.

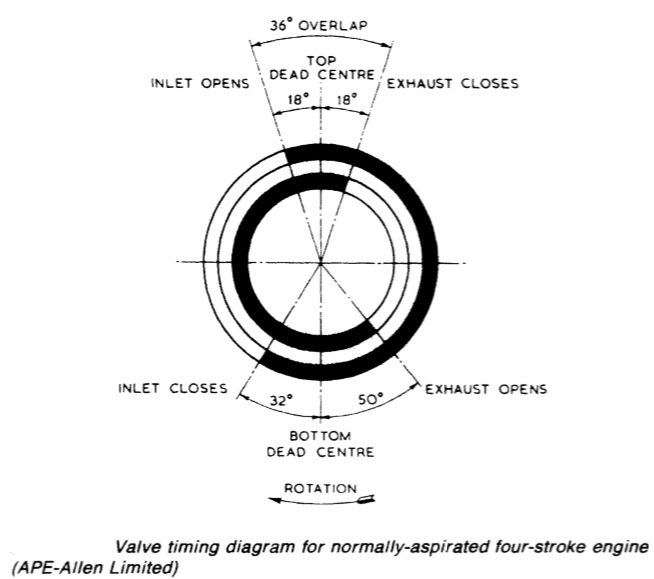

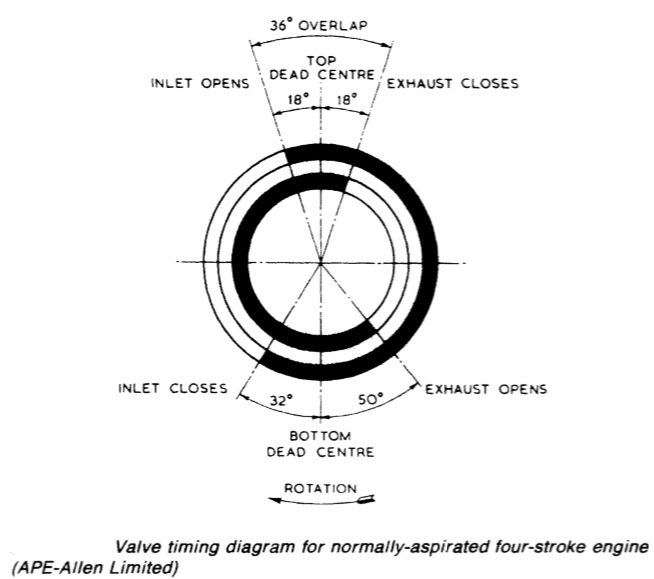

A typical valve

timing diagram (Figure 7.3) shows the large overlap between the opening of

the air inlet and closure of the exhaust compared with the previous normally

aspirated engine (Figure 7.4) which is no longer produced. The overlap allows a

through flow of charge air which is essential for exhaust valve cooling,

particularly for an engine which operates using residual fuel.

Vanadium and

sodium ash from the fuel tends to adhere to valves and seats if their

temperature exceeds the melting point of the ash. The deposited ash itself

causes surface damage in the form of pitting and also tends to prevent closure.

Valve surface temperature should ideally not exceed 420°C if ash deposit is to

be avoided. Localized high surface temperature can be prevented on that part

of the valve adjacent to the fuel injector by the rotator. Valve surfaces can be

protected by a stellite deposit or, alternatively, valves can be made from nimonic.

The turbo-blower, mounted at the free end of the engine, has a filter/silencer

fitted on the air intake. The charge air cooler is similar to that described in

Chapter I,

Turbochargers

The turbocharger is driven by the exhaust gas leaving the cylinders of the

diesel engine it serves. The gas has sufficient pressure and heat when released

from the cylinder at exhaust opening, to drive the turbocharger. It is directed

on to turbine blades by nozzles which are built into a nozzle ring in the axial

flow type or into a radial turbine from the peripheral volute casing of smaller

turbochargers.

Figure 7.4 Valve timing diagram for normally-aspirated four-stroke engine

(APE-Allen Limited)

A small turbocharger for a generator diesel prime mover may be driven by a

radial flow gas turbine, which closely resembles the impeller it drives. This type

of machine costs less to manufacture than the axial flow turbine, and has a

simpler construction.

Turbocharger blades are rotated, partly by the impact of jets of gas from the

nozzles and partly by the reaction, as gases leave the blades. Correct nozzle and

blade shape is vital. Performance of turbocharger and engine can deteriorate

seriously with sometimes very moderate surface marking due to erosion or

corrosion.

Nozzle shape can be altered in service, by:

1 deposit build up;

2 corrosion of surfaces;

3 erosion, by solids entrained in the exhaust gas.

Oil refinery residuals are used in a blend with clean distillate fuels for

economy in some engines. Deposits are common when heavy residual fuel is

used. Regular cleaning is necessary to prevent nozzle blockage. Water washing

rather than dismantling and cleaning is used for deposit removal. Fittings

should be provided for water washing if an engine is to be operated using

residual fuel.

Corrosion is a potential problem for the turbochargers of engines which

operate using residual fuels containing vanadium, sodium and sulphur as

impurities and in a marine environment where sodium chloride is present in the

intake air. The impurities listed burn to form a number of different ash products

which may adhere to surfaces at higher temperatures. Corrosion and surface

damage follows breakdown of the protective film on the metal surface by ash

compounds.

Remedies for these problems are based on designing for lower operating

temperatures and regular water washing to remove the accumulated slag (ash).

Corrosion problems are well known and documented in various technical

papers such as those of the Institute of Marine Engineers.

Erosion by solids entrained in the exhaust gas is another potential problem.

Catalytic fines (based on aluminium and silicon which are abrasive) will be

present in some fuels and could cause surface damage to nozzles. Purification of

fuels is necessary to remove solids and where catalytic fines are suspected, the

use of centrifuges arranged as two purifiers in parallel or a purifier and a clarifier

in series is recommended .

Serious damage by corrosion or erosion will finally require renewal of parts

if the efficiency of the turbocharger and diesel is to be maintained.

Summarized below some of the basic procedure of marine auxiliary machinery :

- Auxiliary engine general construction

Major problems have been experienced on large slow-speed

engines with some of the poor quality bunkers such as those containing

catalytic fines. Fuel should conform to the specification given in the instruction

book for the engine.

......

- Auxiliary engine back pressure turbine

Many ships have used an auxiliary steam turbine as a primary pressure reducing stage before passing the steam to other auxiliaries demanding steam at a substantially lower pressure than that available. Such an arrangement gives a heat balance which is far more favourable than that obtained with a pressure reducing valve......

- Auxiliary engine fuel pump

The most common fuel pump used on auxiliary diesel engines is the Bosch

type. This is a cam operated jerk pump with a helical groove on the plunger to

control the fuel cut-off and therefore the quantity of fuel delivered to the

cylinder for combustion.

......

- Auxiliary engine common fuel injector

Fuel is delivered to an annular space in the nozzle via a hole, drilled through

the nozzle body from the inlet. The nozzle valve is forced from its seat in the

nozzle body by the pressure of fuel from the pump, acting on the shoulder of

the needle valve.

......

- Auxiliary engine cooling system

A variety of cooling systems may be adopted for marine auxiliary engines but

the most commonly used is the simple closed circuit system . Sea

water is passed through the intercooler, the oil cooler and then the jacket water

cooler in series flow.

......

- Auxiliary engine hydraulic governor

When used for alternating current power generation, a diesel engine is normally fitted with a hydraulic governor. This incorporates a centrifugal speed sensing device (spring loaded flyweights) controlling a suitably damped oil operated servo-cylinder through a pilot valve.

......

- Auxiliary engine speed governing system

Unlike propulsion turbines, generator turbines work at constant speed and must be governed accordingly. Classification Society rules require that there must be only a 10% momentary and a 6% permanent variation in speed when full load is suddenly taken off or put on.

......

- Auxiliary engine tracing faults

The failure of an engine to start or problems while running may be traced to

faults with the fuel injection system or other possible causes. Instruction

manual guidance on fault finding and remedies will include some of the typical

problems

......

- Generators driven from the main propulsion

Generators can variously be driven from the propeller shaft, through a gearbox or by being mounted on the engine itself.

......

- Exhaust gas boilers

The original exhaust gas boilers or economizers were of simple construction and produced, from the low powered engines of the time, a very moderate amount of steam. As large slow speed engine powers increased, the larger quantity of steam that could be generated from otherwise wasted exhaust energy,

......

- Auxiliary engine Turbo generator construction

Turbo-generator construction-For electrical power generation, turbines are conventionally horizontal axial flow machines of the impulse reaction type. They may exhaust either to an integral condenser (invariably underslung) or to a separate central auxiliary condenser or the ship's main condenser.

......

- Caterpillar engine fuel system

The range of larger Caterpillar engines use helix-type fuel pumps driven from a

separate camshaft.......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||