Home page||Auxiliary Power ||

Marine auxiliary engine fuel pump - Bosch type

Bosch type fuel pump :

The most common fuel pump used on auxiliary diesel engines is the Bosch

type. This is a cam operated jerk pump with a helical groove on the plunger to

control the fuel cut-off and therefore the quantity of fuel delivered to the

cylinder for combustion.

These pumps can be arranged singly along the

camshaft, with one at each cylinder position or they may be housed in a single

block. Each pump unit contains a pump plunger and guide together with a

spring loaded delivery valve and its seat. Plungers and guides are not

interchangeable — they should be treated as combined units or elements.

Operation :

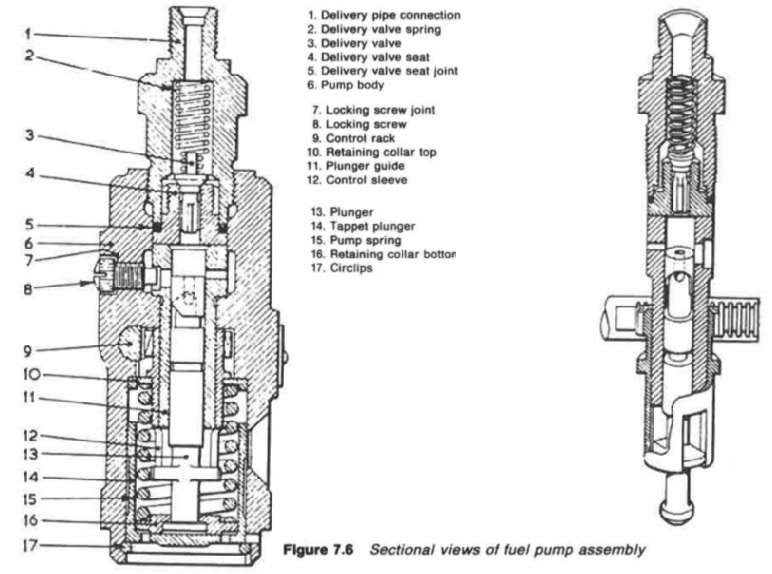

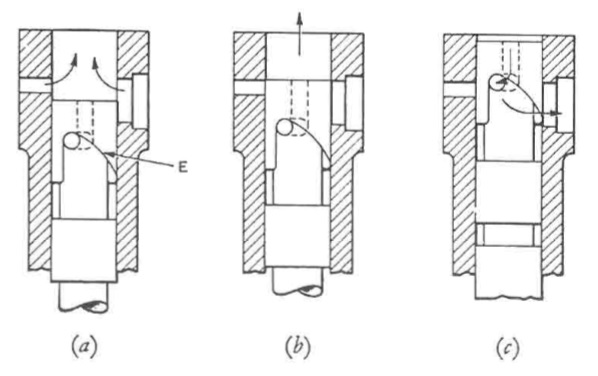

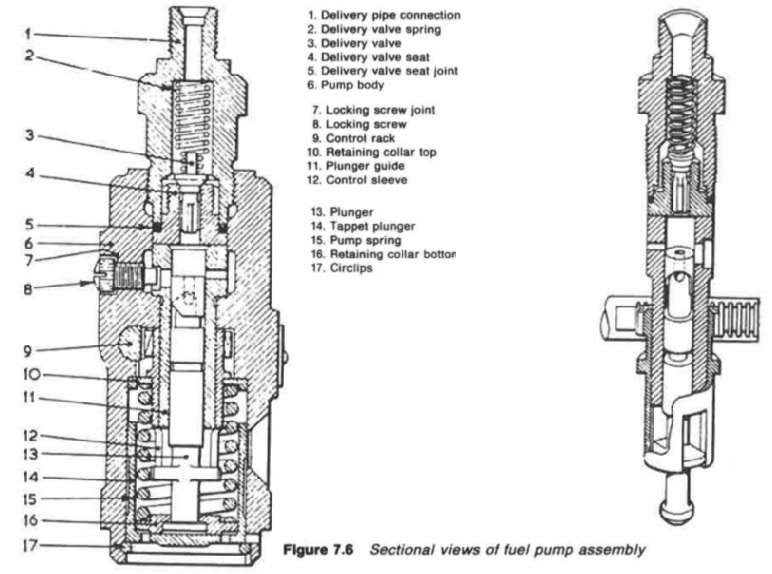

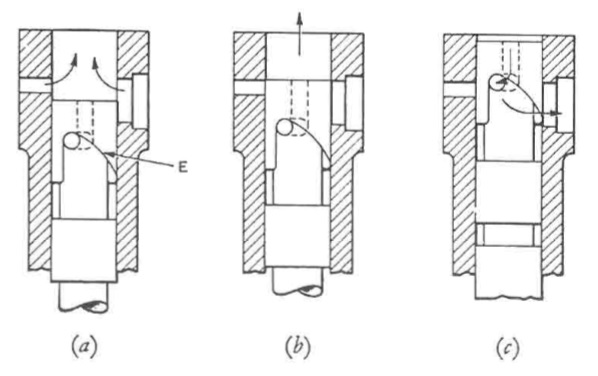

The operation of helix type pumps is shown diagrammatically in Figure 7.6.

With the plunger E at the lower limit of its travel (Figure 7.6a) fuel enters the

barrel from the surrounding suction chamber, through the two ports. As the

plunger rises, some fuel is displaced through the ports until they are just closed

(Figure 7.6b) by the top edge of the plunger. Fuel trapped above the plunger is

now forced out through the delivery valve above the top of the pump barrel.

Figure

Figure : Sectional views of fuel pump assembly

Figure 7.6:a,b,c Sectional views of fuel pump assembly

- 1. Delivery pipe connection

-

2. Delivery valve spring

- 3. Delivery valve

- 4. Delivery valve seat

- 5. Delivery valve seat joint

- 6. Pump body

- 7. Locking screw joint

- 8. Locking screw

- 9. Control rack

- 10. Retaining collar top

- 11. Plunger guide

- 12. Control sleeve

- 13. Plunger

- 14. Tappet plunger

- 15. Pump spring

- 16. Retaining collar bottom

- 17. Circlips

The pressure exerted by the rising plunger causes fuel to lift the valve and to

enter the pipe which connects the pump to the injector. As the pipe is already

full, the extra fuel which is being forced in, causes a rise in the pressure

throughout the line and lifts the needle valve of the injector. This causes fuel to

be forced into the combustion chamber in the form of a fine spray.

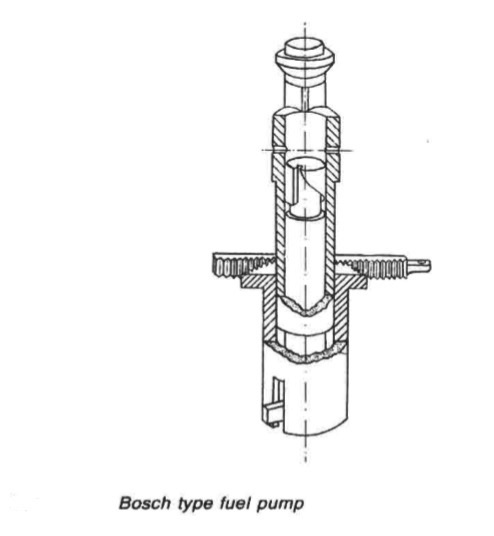

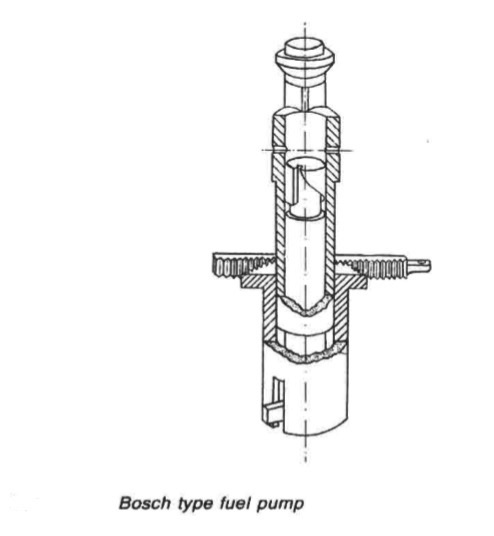

Figure 7.7 Bosch type fuel pump

As the plunger continues to move upwards, the lower edge of the control

helix uncovers the spill port, allowing fuel to be bypassed from the barrel

suction chamber through the vertical drilled hole in the plunger or via a

machined slot or channel (Figure 7.7). This allows the delivery valve to shut

under the action of its spring, and with the collapse of pressure in the pipeline,

the injector also shuts. At the junction between the delivery valve and its

guide, there is a short plane cylindrical piston which fills the seat aperture as the

valve closes. This emphasizes pressure drop in the delivery pipe so that the

injector closes sharply.

The actual plunger stroke is constant, but an effective stroke depends on

which part of the helix is moving up and down in line with the spill port. The

effective stroke can be set between maximum fuel and no fuel. The latter

setting, means that fuel spills for the full length of the plunger stroke. The

plunger is moved around to the required position by the rack and quadrant

(Figure 7.7).

The quadrant collar is on a sleeve which has two vertical slots at

the bottom. Two lugs projecting from the lower part of the plunger move up

and down in these slots as the plunger reciprocates. Rotary movement of the

sleeve (which has no vertical motion) moves the plunger. The rack which

meshes with the toothed quadrant is externally connected to suitable linkage

from the governor and the manual control lever.

Summarized below some of the basic procedure of marine auxiliary machinery :

- Auxiliary engine general construction

Major problems have been experienced on large slow-speed

engines with some of the poor quality bunkers such as those containing

catalytic fines. Fuel should conform to the specification given in the instruction

book for the engine.

......

- Auxiliary engine back pressure turbine

Many ships have used an auxiliary steam turbine as a primary pressure reducing stage before passing the steam to other auxiliaries demanding steam at a substantially lower pressure than that available. Such an arrangement gives a heat balance which is far more favourable than that obtained with a pressure reducing valve......

- Auxiliary engine fuel pump

The most common fuel pump used on auxiliary diesel engines is the Bosch

type. This is a cam operated jerk pump with a helical groove on the plunger to

control the fuel cut-off and therefore the quantity of fuel delivered to the

cylinder for combustion.

......

- Auxiliary engine common fuel injector

Fuel is delivered to an annular space in the nozzle via a hole, drilled through

the nozzle body from the inlet. The nozzle valve is forced from its seat in the

nozzle body by the pressure of fuel from the pump, acting on the shoulder of

the needle valve.

......

- Auxiliary engine cooling system

A variety of cooling systems may be adopted for marine auxiliary engines but

the most commonly used is the simple closed circuit system . Sea

water is passed through the intercooler, the oil cooler and then the jacket water

cooler in series flow.

......

- Auxiliary engine hydraulic governor

When used for alternating current power generation, a diesel engine is normally fitted with a hydraulic governor. This incorporates a centrifugal speed sensing device (spring loaded flyweights) controlling a suitably damped oil operated servo-cylinder through a pilot valve.

......

- Auxiliary engine speed governing system

Unlike propulsion turbines, generator turbines work at constant speed and must be governed accordingly. Classification Society rules require that there must be only a 10% momentary and a 6% permanent variation in speed when full load is suddenly taken off or put on.

......

- Auxiliary engine tracing faults

The failure of an engine to start or problems while running may be traced to

faults with the fuel injection system or other possible causes. Instruction

manual guidance on fault finding and remedies will include some of the typical

problems

......

- Generators driven from the main propulsion

Generators can variously be driven from the propeller shaft, through a gearbox or by being mounted on the engine itself.

......

- Exhaust gas boilers

The original exhaust gas boilers or economizers were of simple construction and produced, from the low powered engines of the time, a very moderate amount of steam. As large slow speed engine powers increased, the larger quantity of steam that could be generated from otherwise wasted exhaust energy,

......

- Auxiliary engine Turbo generator construction

Turbo-generator construction-For electrical power generation, turbines are conventionally horizontal axial flow machines of the impulse reaction type. They may exhaust either to an integral condenser (invariably underslung) or to a separate central auxiliary condenser or the ship's main condenser.

......

- Caterpillar engine fuel system

The range of larger Caterpillar engines use helix-type fuel pumps driven from a

separate camshaft.......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||