Home page||Propeller shaft ||

Propeller Shaft bearings - various type

Propeller shaft, tail shaft – The aftermost section of the propulsion shafting in the stern

tube in single screw ships and in the struts of multiple screw ships to which the propeller

is fitted.

Propulsion shafting constitutes a system of revolving rods that transmit power and motion from

the main drive to the propeller. The shafting is supported by an appropriate number of

bearings.

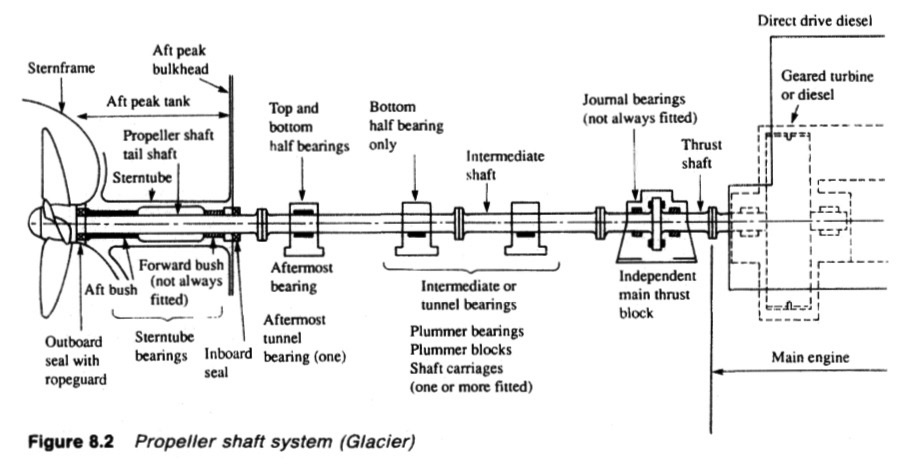

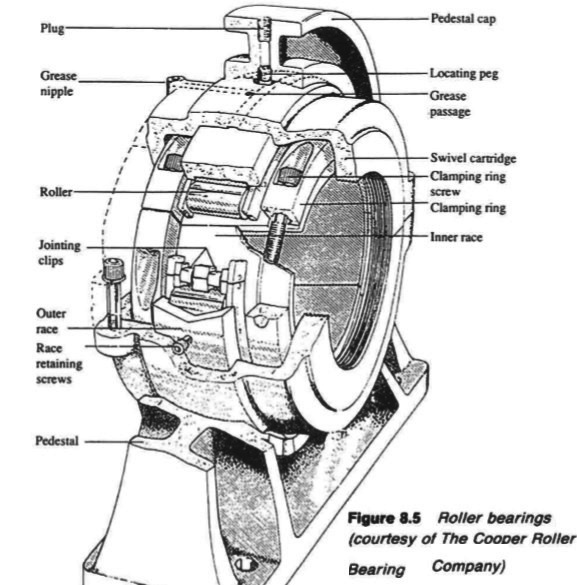

Shaft bearings : The intermediate shafting (Figure 8.2) between the tailshaft and main engine,

gearbox or thrustblock may be supported in plain, tilting pad or roller bearings.

The two former types usually have individual oil sumps, the oil being

circulated by a collar and scraper device; roller bearings are grease lubricated.

The individual oil sumps usually have cooling water coils or a simple cooling

water chamber fitted. Cooling water is provided from a service main connected

to the sea-water circulating system. The cooling water passes directly overboard.

Figure : Propeller shaft system

Usually for plain and tilting pad bearings, only a bottom bearing half is

provided, the top acting purely as a cover. The aftermost plumber block

however, always has a full bearing. This bearing and any bearing in the forward

end of the stern tube, may be subject to negative loading.

Plain bearings

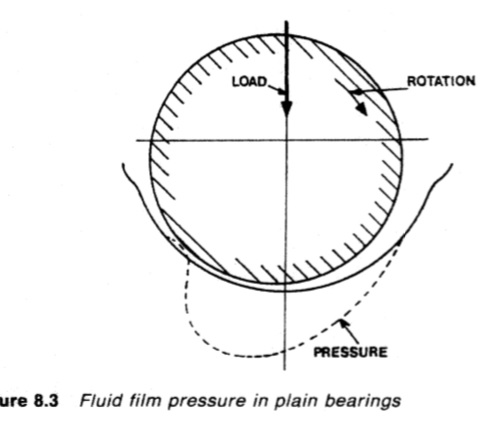

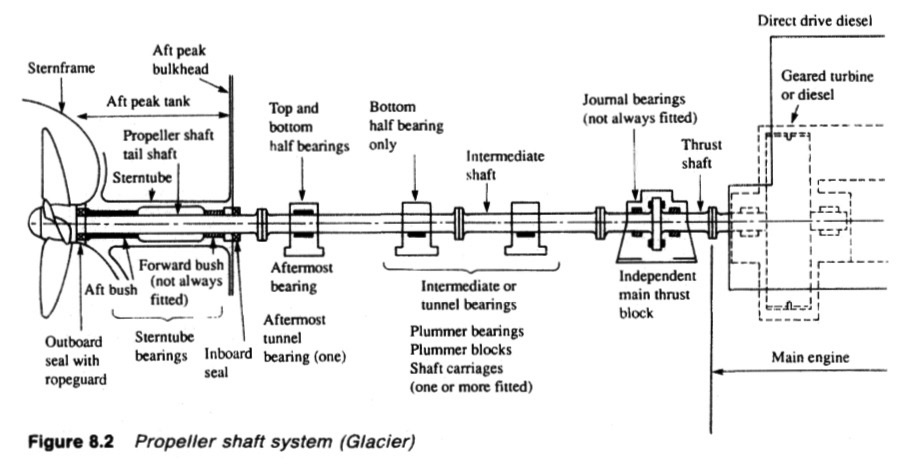

Any oil between a static shaft and plain journal bearing in which it rests, tends

to be squeezed out so that there is metal to metal contact. At the start of the

rotation the journal is inclined to roll up the bearing surface against the

direction of rotation until friction slip occurs. Then, provided there is oil in the

clearance space, this will cling to the moving surface and be dragged between

the shaft and the bearing.

Shaft rotation, as it speeds up, continues to carry oil

to the shaft underside so developing a film with sufficient pressure to hold the

shaft clear of the bearing. The pressure build-up is related to speed of rotation,

Thus oil delivered as the shaft turns at normal speed, will form a layer or film,

separating shaft and bearing, and so prevent direct wear of metal to metal.

Figure : Fluid film pressure in plain bearing

Pressure generated in the oil film, is most effective over about one third of the

bearing area (Figure 8.3) because of oil loss at the bearing ends and

peripherally. Load is supported and transmitted to the journal, mainly by the

area where the film is generated.

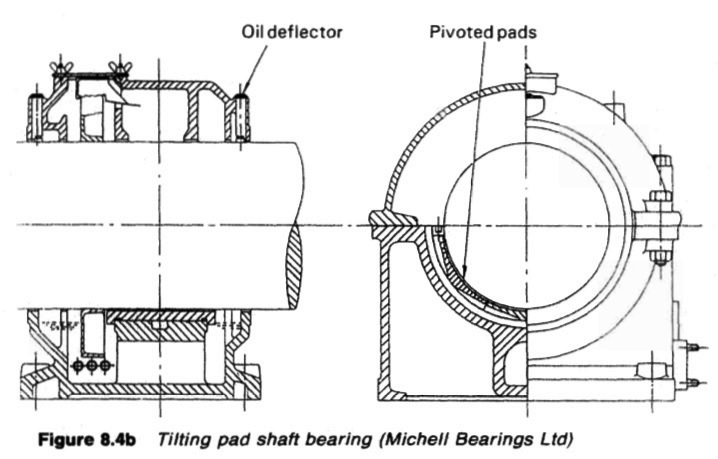

Tilting pad bearings

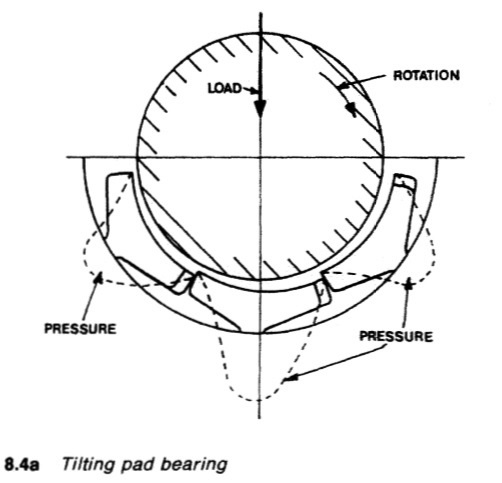

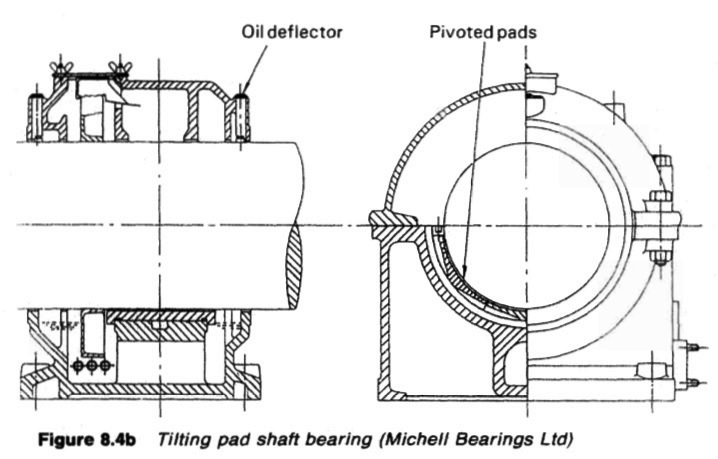

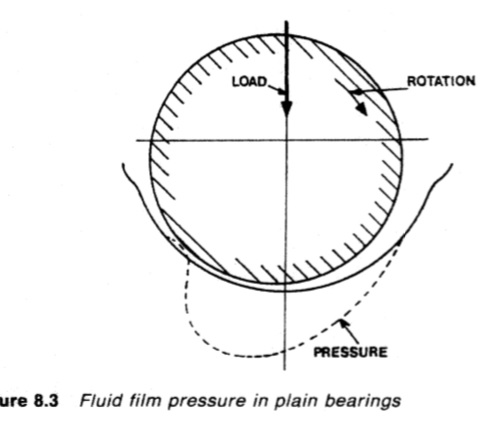

Replacement of the ineffective side portions of the journal by pads capable of

carrying load will considerably increase its capacity. Tilting pads based on

those developed by Michell for thrust blocks (Figure 8.4a) are used for the

purpose. Each pad tilts as oil is delivered to it, so that a wedge of oil is formed.

The three pressure wedges give a larger total support area than that obtained

with a plain bearing. The arrangement of pads in a bearing is shown in Figure

8.4b.

The tilt of the pads automatically adjusts to suit load, speed and oil viscosity.

The wedge of oil gives a greater separation between shaft and bearing than

does the oil film in a plain journal. The enhanced load capacity of a tilting pad

design, permits the use of shorter length bearings or fewer bearings.

Figure : Tilting pad bearing

Figure :Tilting pad shaft bearing (Michell Bearings Ltd)

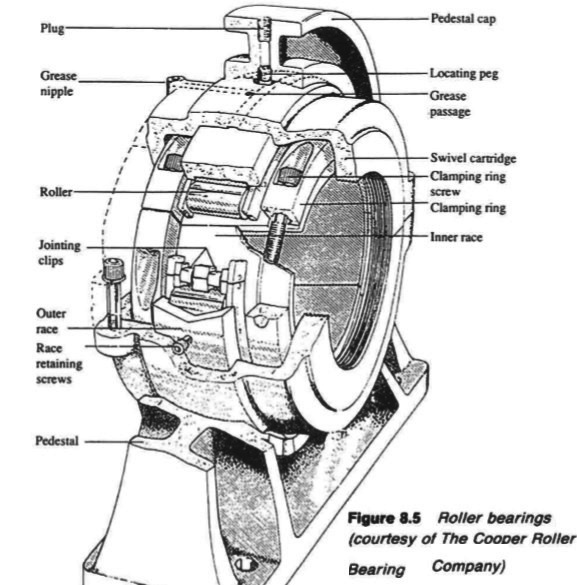

Roller bearings

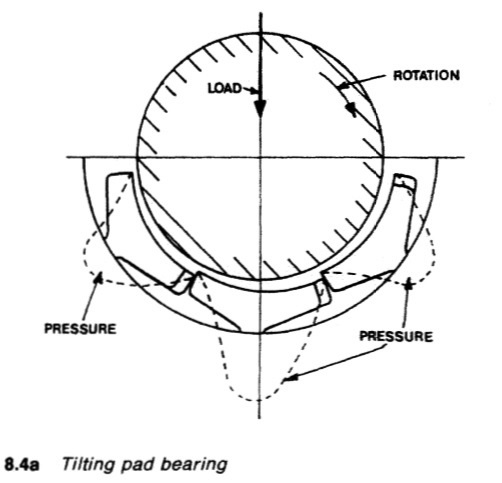

Roller bearings (Figure 8.5) are supplied in sizes to suit shafts up to the largest

diameter. Flange couplings dictate that roller bearing races must be in two parts

for fitting.

The section of the shaft where the split roller bearing is to be fitted, must be

machined very accurately and with good finish. The two halves of the inner

and outer races are fitted and held with clamping rings.

Adequate speed for build-up of fluid film pressure is vital for journal

bearings. At low speeds there may be metal to metal contact with wear and

damage. Friction at low rotational speeds, is high. Roller bearings are not

dependent on speed for effective lubrication. Friction is low at all speeds. This

makes them suitable for steam turbine installations and in ships where slow

steaming may be necessary. Roller bearings, where fitted, are grease-lubricated.

Figure : Roller bearings (courtesy of The Cooper Roller Bearing

Company)

Summarized below some of the basic procedure of marine propeller shaft :

- Propeller shaft materials and couplings

The intermediate shafting and the propeller shaft for a fixed propeller are of

solid forged ingot steel and usually with solid forged couplings. Shafts are

machined all over but of a larger diameter and smooth turned in way of the

bearings.

......

- Fixed pitch propeller

The normal method of manufacture for a fixed pitch propeller, is to cast the blades integral with the boss and after inspection and marking, to machine the

tapered bore and faces of the boss before the blades are profiled by hand with reference to datum grooves cut in the surfaces or with an electronically controlled profiling machine.

......

- Controllable pitch propeller

Controllable pitch propellers are normally fitted to a flanged tailshaft as the operating mechanism is housed in the propeller boss. As its name implies, it is possible to alter the pitch of this type of propeller to change ship speed or to adjust to the prevailing resistance conditions.

......

- Propeller thrust block

The main thrust block transfers forward or astern propeller

thrust to the hull and limits axial movement of the shaft. Some axial clearance is essential to

allow formation of an oil film in the wedge shape between the collar and the

thrust pads

......

- Propeller shaft gears and clutches

For medium-speed engine installations in large ships (as opposed to coasters or intermediate sized vessels) reduction gears are needed to permit engines and propellers to run at their best respective speeds. Their use also permits more than one engine to be coupled to the same propeller. Gearboxes are available from manufacturers in standard sizes.

......

- Propeller shaft check

The intention of good alignment is to ensure that bearings are correctly loaded

and that the shaft is not severely stressed. Alignment can be checked with

conventional methods, employing light and targets, laser or measurements

from a taut wire.

......

- Propeller shaft bearings check

The intermediate shafting between the tailshaft and main engine,

gearbox or thrustblock may be supported in plain, tilting pad or roller bearings.

......

- Oil lubricated stern tube

Progress from sea-water to early oil-lubricated stern tubes involved an

exchange of the wooden bearing in its bronze sleeve for a white metal

lined cast iron (or sometimes bronze) bush. Oil retention and exclusion of

sea water necessitated the fitting of an external face type seal.

......

- Water lubricated stern tube

The traditional stern bearing is water-lubricated and consists of a

number of lignum vitae staves held by bronze retaining strips, in a gunmetal

bush. Lignum vitae is a hardwood with good wear characteristics and is

compatible with water.

......

- Stern tube sealing arrangement

There are basically three sealing arrangements used for stern bearings. These are:

Simple stuffing boxes filled with proprietary packing material. Lip seals, in which a number of flexible membranes in contact with the

shaft, prevent the passage of fluid along the shaft.

& Radial face seals, in which a wear-resistant face fitted radially around the

shaft,

......

- Stern tube bearings

To avoid the necessity for drydocking when an examination of stern bearings

amid tailshaft is needed, split stern bearings were developed. A suitable

outboard sealing arrangement and design, permits the two halves of the

bearing to be drawn into the ship, exposing the shaft and the white metal

bearing.

......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||