Home page||Propeller shaft ||

Stern tube sealing arrangements- Marine propeller shaft Guideline

There are basically three sealing arrangements used for stern bearings. These are:

- Simple stuffing boxes filled with proprietary packing material.

- Lip seals, in which a number of flexible membranes in contact with the

shaft, prevent the passage of fluid along the shaft.

- Radial face seals, in which a wear-resistant face fitted radially around the

shaft, is in contact with similar faces fitted to the after bulkhead and to the

after end of the stern tube. A spring system is necessary to keep the two

faces in contact.

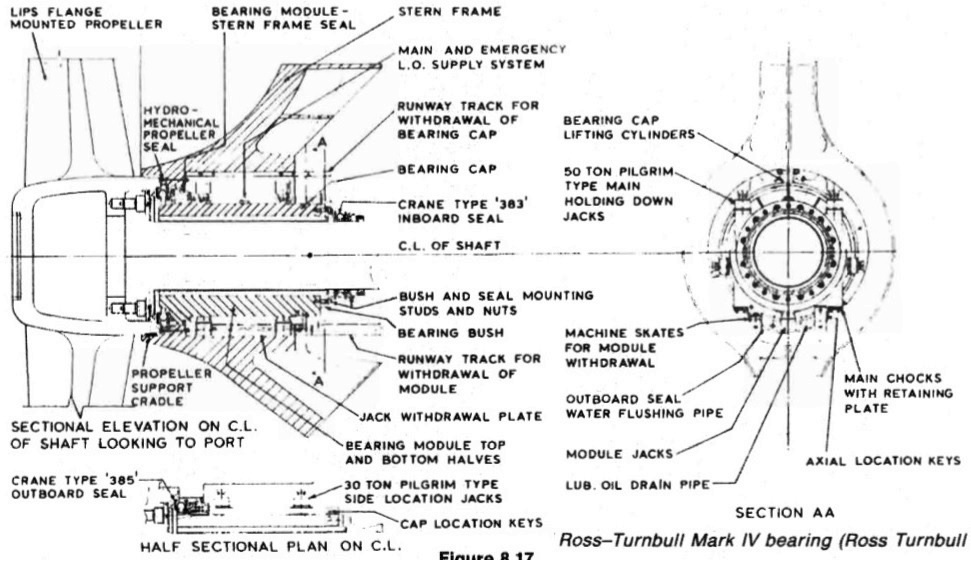

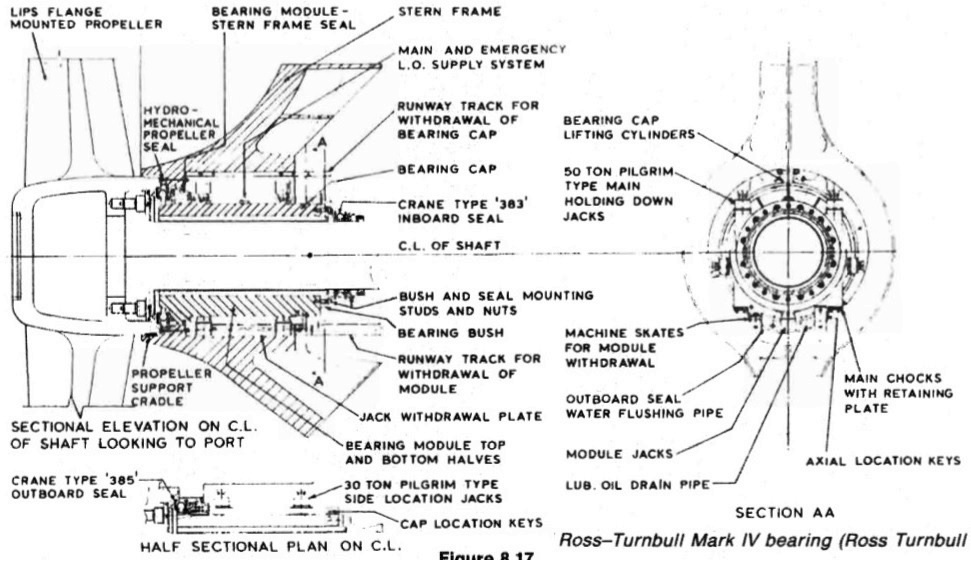

Figure : The Ross-Turnbull split stern bearing

Figure 8,17 General arrangement of Ross-Turnbull Mark IV bearing (Ross Tumbull Ltd.)

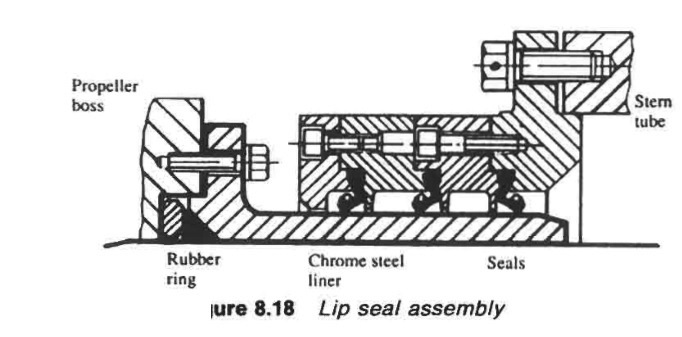

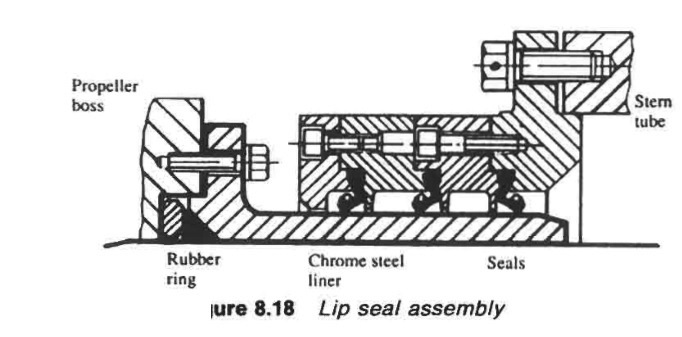

Lip seals

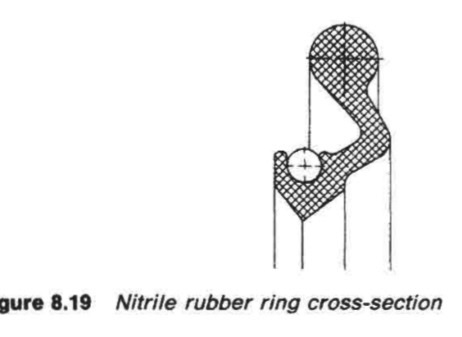

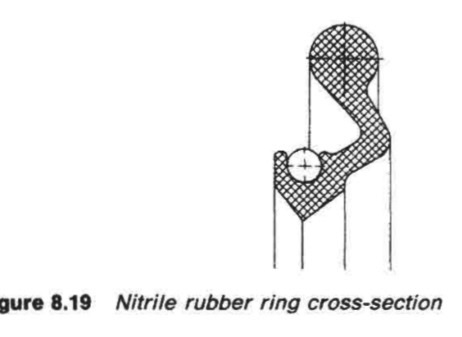

A lip seal assembly (Figure 8.18) consists of a number of nitrile rubber rings of

special cross-section (Figure 8.19) sandwiched between bronze rings. Each individual

rubber lip seal is held in contact with a renewable sleeve fitted to the shaft by

its elasticity and a garter spring. The rings are renewed by cutting and then vulcanizing

the ends in situ. The Simplex stern tube (Figure 8.15) has a forward seal

with two rings and an after seal with three rings.

A larger sketch of the after seal

(Figure 8.18) shows how seals are built up from three basic assemblies namely

the flange, intermediate, and cover rings and these parts can be used for either

seal. It will be noticed that the garter spring holding the sealing ring against the

shaft is located aft of the ring anchoring bulb in the case of both forward sealing

rings.

In the case of the after seal the two outboard sealing rings have their garter

springs located aft of the ring anchoring bulbs while the inboard ring has its

garter spring located inboard of the anchoring bulb. Lip seals will accept

misalignment but a floating ring design was introduced by one manufacturer.

In some instances four or more sealing rings are installed. These are arranged

so that one ring does not normally run on the shaft liner. In the event of leakage

from the working seals, adjustment is made to bring the reserve ring into play,

Figure : Lip seal assembly

Figure : Nitrile rubber ring cross-section

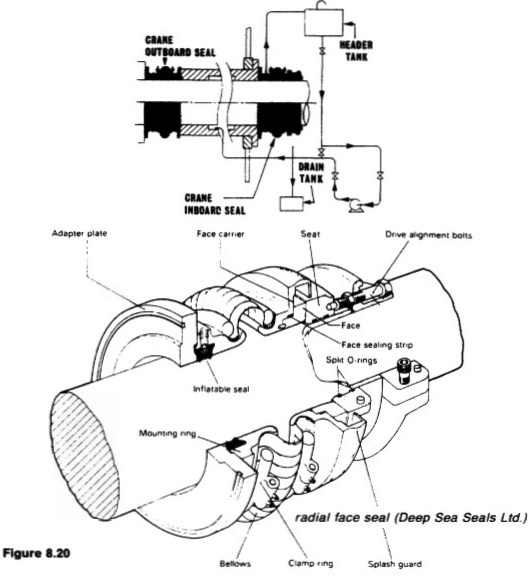

Radial face seal

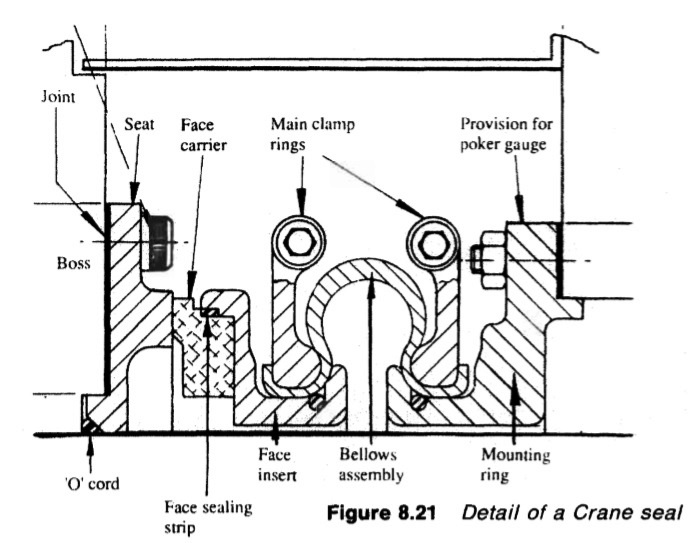

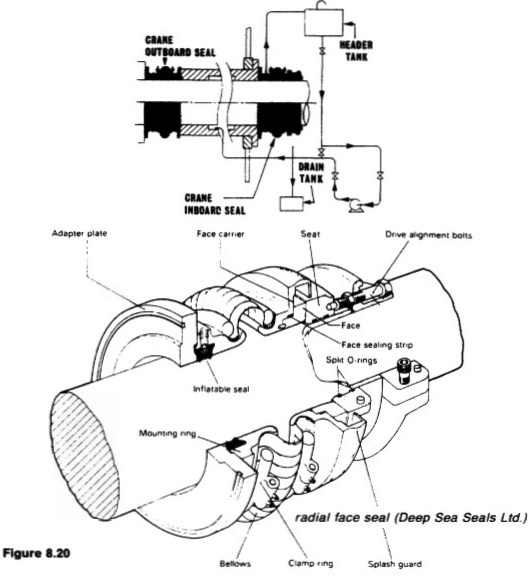

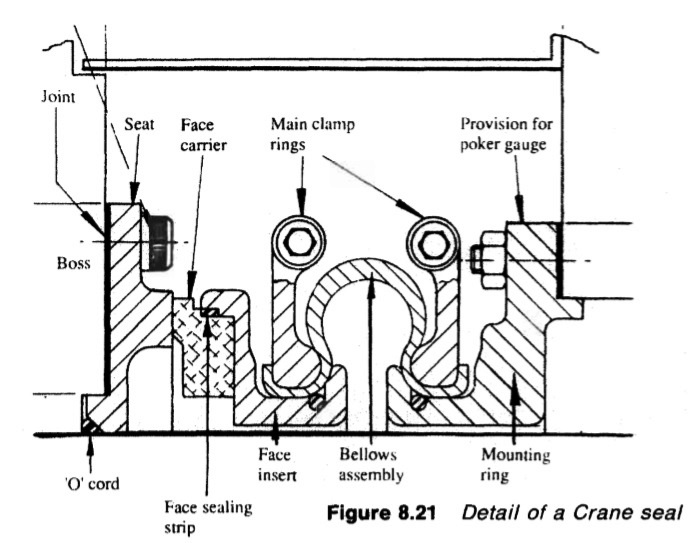

An example of a radial face seal, is shown in the general arrangement (Figure

8,20) and a detailed sketch (Figure 8.21) of a Crane seal. One of the principal

features of the design and construction of this type of seal is the split

construction of all component parts. This facilitates installation, and subsequent

inspection and maintenance.

The function of sealing against leakage around the shaft is effected by

sustaining perfect mating contact between the opposing faces of the seal's seat

which rotates with the shaft, and of the main seal unit which is stationary and

clear of the shaft.

This mating contact of the seal faces, which are hydraulically balanced, is

sustained by spring pressure and by the method of flexibly mounting the face

of the main seal unit. The flexible member consists of a tough, but supple,

reinforced bellows. Thus the main seal unit is able to accommodate the effects

of hull deflection and vibration.

Figure :Example of a radial face seal (Deep Sea Seals Ltd.)

Figure : Detail of a Crane seal

The bellows member is clear of the shaft, and its flexibility therefore cannot

be impaired, as may happen when a flexible member is mounted on the shaft

and hardens, seizes or becomes obstructed by a build-up of solids. The

mechanical design principles also ensure continued sealing under fluctuating

pressure conditions, i.e. changing draught.

An emergency sealing device can be incorporated into the design. The

device, when inflated with air or liquid, forms a tight temporary seal around the

shaft, enabling repairs to be made or a replacement seal fitted when the ship is

afloat, without the shaft being drawn or drydocking being necessary,

Summarized below some of the basic procedure of marine propeller shaft :

- Propeller shaft materials and couplings

The intermediate shafting and the propeller shaft for a fixed propeller are of

solid forged ingot steel and usually with solid forged couplings. Shafts are

machined all over but of a larger diameter and smooth turned in way of the

bearings.

......

- Fixed pitch propeller

The normal method of manufacture for a fixed pitch propeller, is to cast the blades integral with the boss and after inspection and marking, to machine the

tapered bore and faces of the boss before the blades are profiled by hand with reference to datum grooves cut in the surfaces or with an electronically controlled profiling machine.

......

- Controllable pitch propeller

Controllable pitch propellers are normally fitted to a flanged tailshaft as the operating mechanism is housed in the propeller boss. As its name implies, it is possible to alter the pitch of this type of propeller to change ship speed or to adjust to the prevailing resistance conditions.

......

- Propeller thrust block

The main thrust block transfers forward or astern propeller

thrust to the hull and limits axial movement of the shaft. Some axial clearance is essential to

allow formation of an oil film in the wedge shape between the collar and the

thrust pads

......

- Propeller shaft gears and clutches

For medium-speed engine installations in large ships (as opposed to coasters or intermediate sized vessels) reduction gears are needed to permit engines and propellers to run at their best respective speeds. Their use also permits more than one engine to be coupled to the same propeller. Gearboxes are available from manufacturers in standard sizes.

......

- Propeller shaft check

The intention of good alignment is to ensure that bearings are correctly loaded

and that the shaft is not severely stressed. Alignment can be checked with

conventional methods, employing light and targets, laser or measurements

from a taut wire.

......

- Propeller shaft bearings check

The intermediate shafting between the tailshaft and main engine,

gearbox or thrustblock may be supported in plain, tilting pad or roller bearings.

......

- Oil lubricated stern tube

Progress from sea-water to early oil-lubricated stern tubes involved an

exchange of the wooden bearing in its bronze sleeve for a white metal

lined cast iron (or sometimes bronze) bush. Oil retention and exclusion of

sea water necessitated the fitting of an external face type seal.

......

- Water lubricated stern tube

The traditional stern bearing is water-lubricated and consists of a

number of lignum vitae staves held by bronze retaining strips, in a gunmetal

bush. Lignum vitae is a hardwood with good wear characteristics and is

compatible with water.

......

- Stern tube sealing arrangement

There are basically three sealing arrangements used for stern bearings. These are:

Simple stuffing boxes filled with proprietary packing material. Lip seals, in which a number of flexible membranes in contact with the

shaft, prevent the passage of fluid along the shaft.

& Radial face seals, in which a wear-resistant face fitted radially around the

shaft,

......

- Stern tube bearings

To avoid the necessity for drydocking when an examination of stern bearings

amid tailshaft is needed, split stern bearings were developed. A suitable

outboard sealing arrangement and design, permits the two halves of the

bearing to be drawn into the ship, exposing the shaft and the white metal

bearing.

......

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||