Home page||Marine Pumps ||

Rotary displacement pump - how the system works

Rotary displacement pumps:

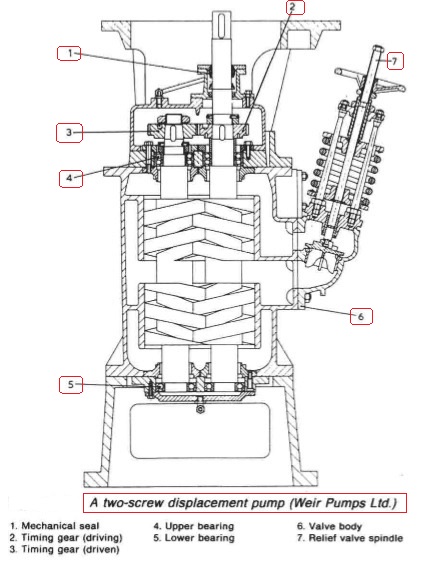

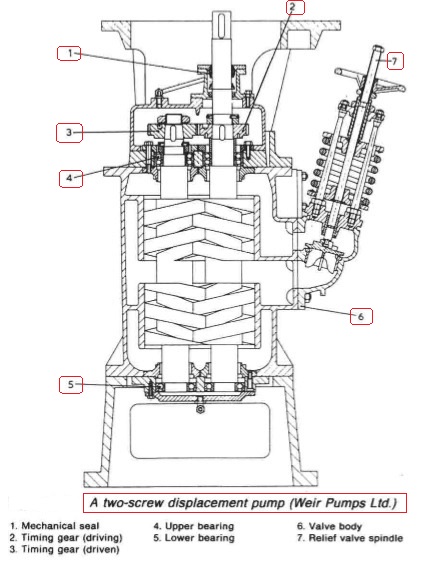

Positive displacement rotary pumps rely on fine clearances between moving

parts for their efficient operation. Excessive wear or erosion of parts, due to

friction contact or the presence of abrasives, is avoided by employing this type

of pump for specialized rather than general duties. Contact between elements

in some screw pumps (Figure 1) is made unnecessary by gear drives. When

used for lubricating oil and hydraulic systems, rotary displacement pumps

benefit from the sealing effect and provision of lubrication between parts.

Pumped volume

For a rotary positive displacement pump operating at zero pressure the

volumetric efficiency should be 100% but as the differential pressure increases

the amount of leakage (slip) through clearances will increase. This

slip (the terminology normally used) will naturally be less the more viscous the

pumped liquid is, for any given pressure. It should also be noted that the slip,

being a function of the clearance, viscosity and differential pressure, is constant

irrespective of running speed. In practice, changes in flow conditions affect this

slightly.

Slip or leakage can cause erosion and increase of clearances,

particularly when the liquid being pumped contains abrasives.

Pressure is limited by the torque available from the drive motor, the strength

of parts, the amount of slip or leakage and considerations of overall efficiency,

Power

The power requirement of the pump may be split into two components,

namely hydraulic power and frictional power. The hydraulic power is that

required for the pumped medium. Since slip is only 'slip' because it has been

pumped and then leaked back via the clearances, it is only necessary to consider

the pump displacement at its running speed, and the differential pressure

through which the liquid is being raised. Frictional loss is minimal where rotors

are not in contact.

Acceleration forces

These are by far the greatest losses in a rotary pump and the liquid properties

are beyond the designers' control. This leaves only the distance of movement

of the dynamic unit and speed within the designers' control (acceleration is a

function of both).

Depth and form of tooth influence this in a gear pump. With the screw

pump, the pitch of the screw is the major factor. Thus high helix angle screws

can be used up to a relatively high speed on small pumps, and lower helix

angles on larger pumps, to keep the pitch within limits set by the field

requirements for suction performance.

Figure 1: Two screw displacement pump

Figure 1: A two-screw displacement pump (Weir Pumps Ltd.)

Summarized below some of the basic procedure of marine pumps and pumping system onboard :

- Axial flow pumps

An axial flow pump is one in which a screw propeller is used to create an increase in pressure by causing an axial acceleration of liquid within its blades. The incidental rotation imparted to the liquid is converted into straight axial movement by suitably shaped outlet guide vanes.....

- centrifugal pumps

Rotation of a centrifugal pump impeller causes the liquid it contains to move outwards from the centre to beyond the circumference of the impeller. The revolving liquid is impelled by centrifugal effect.....

- Centrifugal pump cavitation

Because of their self-priming ability, positive displacement pumps are widely used for lubricating oil duties. This practice is completely satisfactory in installations where the pump speed is variable but when the pump is driven by a constant speed a.c. motor it is necessary to arrange a bypass which can be closed in to boost flow. ....

- Gear pumps

Diesel engine and gearbox lubrication systems are normally supplied by gear

pumps which are independently driven for large slow speed engines and

stand-by duties but usually shaft driven for medium and high speed engines.

Gear pumps are also used for fuel and oil transfer, boiler combustion systems

and other duties.....

- General pumping system characteristics

A pump divides its pipe system into two distinct parts, each with different

characteristics. These are the suction and discharge sides. On the suction side

the drop in pressure that can be produced by a pump is limited to that of an

almost perfect vacuum. On the discharge side there is theoretically, no limit to

the height through which a liquid can be raised.....

- General purpose pumps

Single entry general purpose pumps are used for salt and fresh water circulating and also for bilge and ballast duties. The impeller is suspended from the shaft with no bottom support. ....

- Lobe pumps

Lobe pumps as manufactured by Stothert and Pitt have inner and outer

elements which rotate in a renewable liner fitted in the pump body. The inner

rotor is eccentric to the outer and is fitted to a shaft located by bearings in the

pump covers....

- Marine pumps construction

Marine pumps are usually installed with the shaft vertical and the motor above the pump. This positions the pump as low as possible for the best NPSH, takes up the least horizontal space and leaves the electric motor safer from gland or other leakage.....

- Pumps erosion

A pump handling liquids which contain abrasives, will suffer erosion on all internal surfaces, including bearings and shaft seals. The sea-water circulating pumps of ships operating in waters that contain large quantities of silt and sand

require frequent renewal of shaft seals or packing, also of shaft sleeves in way of the gland and bearings.....

- Rotary displacement pump

Positive displacement rotary pumps rely on fine clearances between moving

parts for their efficient operation. Excessive wear or erosion of parts, due to

friction contact or the presence of abrasives, is avoided by employing this type

of pump for specialized rather than general duties......

- Screw pumps

Both double-screw pumps, in which the screws are driven in phase by timing

gears , and triple screw pumps , in which the centre

screw is driven and the outer screws idle are used at sea especially for pumping

high viscosity liquids such as oil and some liquid cargoes.....

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship design

||Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||