Home page||Ship employment

||

Unitised cargo handling technics - general cargo ship procedure

A grouping together of two or more items (usually of a homogeneous nature) and securing them with

banding, glue, shrinkwrap, slings (e.g. clover leaf), to form a unit which, together with a base (skids, pallets,

etc.) or permanent slings, allows mechanical handling equipment (e.g. tynes of a fork lift truck) to lift and

transport the unit.

The advantages of unitisation may include:

- Ease of tallying.

- Reduced breakages.

- Reduced pilferage.

- Faster speed of working between ship and shore (and on ship or shore).

- May make more effective use of vertical storage space in sheds and holds by stacking units 4, 5 or 6

high (possibly with the need to incorporate shelves or racking). Reduced labour requirements when

handling between interfaces.

The disadvantages of unitisation may include:

- Loss of space below decks where the shape of the vessel is not compatible with the shape of the unit.

- Loss of space caused by the shape of the package being unitised, e.g. drums on pallets.

- Collapsed or crushed units require labour intensive efforts to rectify, handle and store.

- An element of extra cost involved in the pallet; slings; skids; shrink-wrap; strapping, etc.

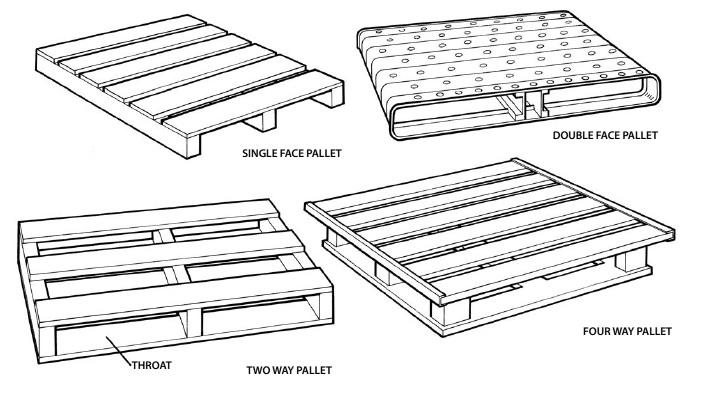

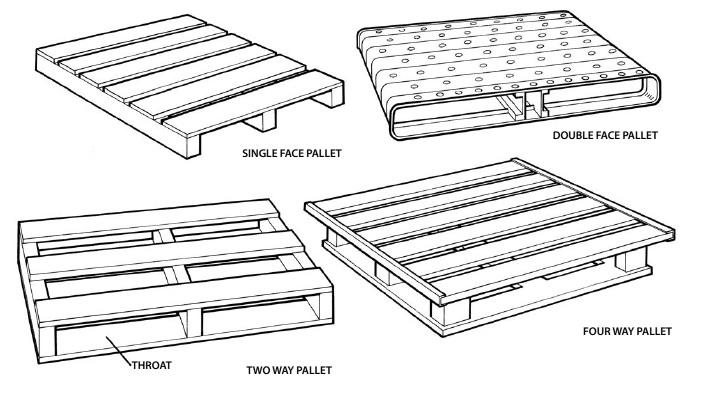

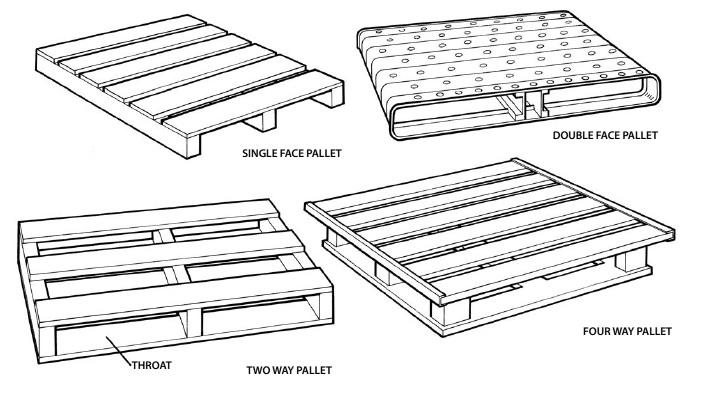

Pallet types

Pallet Sizes

The overall height of a pallet may be from 100mm (4) to 150mm (6), depending on the construction

(single-deck, double-deck, etc.) and the use to which it will be put (single trip, pallet racking, etc.).

The deck (or plan) size depends on a number of factors:

- Size of cargo to be palletised.

- Type of cargo to be palletised (e.g. drums, bags, etc.).

- The use to which it will be put: e.g. closed circuit pool, one trip only, inland/ocean transport

requirements, etc.

ISO have set some standard sizes:-

1,000mm×800mm (40×32)

- 1,200mm×800mm (48×32)

- 1,200mm×1,000mm (48×40)

- 1,200mm×1,600mm (48×64)

- 1,200mm×1,800mm (48×72)

Slip Pads

Sometimes known as slip sheets. These may be made up of a single sheet of fibreboard or plastic, of

the same plan dimensions as a pallet, but with an exposed "lip" which allows the special fitting on a fork

lift truck to grip and pull the slip sheet onto a flat "spade" attachment. Thus the unitmade up on the slip

sheetis handled in all respects as a pallet, except for the special FLT attachment necessary.

The advantages of this system include:

- Saved space; as against pallets or skids. Sometimes particularly important, e.g. low `tween decks,

containers, etc. Pads may be less expensive than pallets.

-

Less storage area required when not being used.

The disadvantages include:

- Pads may be easily damaged; if the "lip" is ripped off then the mechanical handling equipment has

nothing to grip.

-

Requires a flat surface without obstructions on which to operate.

-

Requires special equipment to operate and handle. May (usually) only be approached and handled

from one side; i.e. the side on which the lip protrudes.

Making Up the Unit

The cargo should, as nearly as possible, exactly fit the pallet or slip sheet. Cargo overhanging the deck of

a pallet may cause the following problems:

- Put excessive pressure on the lowest tiers of cargo, particularly that which is in contact with the edge

of the pallet. The g forces generated during transport can force the edge of the pallet deck to penetrate

the cargoparticularly bags and cartonswith resultant damage to the contents.

- Make the securing of the load to the pallet difficult or even impossible.

- Risk the pallet load fouling adjacent cargo or units, with the load becoming wedged or jammed in the

stow.

Similarly a unit module which is too small for the deck of the pallet will make the securing of the cargo

to that pallet less effective, and reduce the ability of ship's bulkheads, container walls, or other cargo to

support the pallet loads laterally in the stow.

The height of a pallet load should be such that the pallet and cargo combined leaves a clearance of at

least:

- 50mm (2) between top of cargo and door header (or ceiling) of a container.

- 150mm (6) between the top of the uppermost pallet and the lowest deck-head obstruction in a `tween

deck or hold.

Method of Securing

The cargo should be secured onto the pallet by one or more of the following methods:

- Strapping:

Man-made fibre or steel. Banding should pass under the top deck of the pallet, to remain clear of

mechanical handling equipment requirements. Some cargo may require protection from the point

loading of the strapping, which may be achieved with scrap dunnage, waste cardboard, etc., or using

proprietary equipment specially designed for the purpose.

Steel strapping may not be suitable for securing cargo that may alter shape or contract, e.g. bags,

telescopic cartons etc. Man-made fibres, particularly nylon, may stretch and allow rigid items to move

in some instances.

- Nets:

Usually of polypropylene, and used to secure awkward shaped packages onto a pallet.

- Glue:

For securing regular stows of cartons or bags. Should be strong in sheer strength, but with little

resistance to a vertical force when dismantling the pallet load. A 5% dextrine solution can be a suitable

mixture for this purpose.

- Shrinkwrap:

A plastic (transparent) cover over the pallet load which is heat shrunk into place. Certain types of

plastic wrapping may be put around the cargo without the need of heat. May be used for most goods

and provide protection against dirt, pilferage, etc.

- Locking Pattern:

Unit loads may be built up on pallets with plan dimensions suited to the modules being handled. In

this way layers may be built up each differing from its neighbours and providing restraint in a similar

manner to a brick wall. Alternate layer patterns are reversed to "tie in" the layer beneath.

The Effect of the Pallet

The pallet, because it raises the cargo approximately 150mm (6) off the deck of the hold, has the effect

of raising the centre of gravity of the cargo which may, in certain circumstances, have to be allowed for.

Pallets use more space than conventional dunnage, perhaps 10 to 14%.

Some overhead space may be lost if the height of the pallet load does not form a module of the height

between decks or in the holds of the shipor the internal height of the container. If the pallets are being made

up on the quay this height may be adjusted (in some instances) to suit the particular height requirements of

the ship. `Tween decks may be designed for "user friendly" palletised cargoes.

While pallet loads may be made up in such a way that the units are suitable for carriage under refrigeration,

the following will need to be taken into consideration:

- The air-flow through the cargo (if required) or around the cargo is not impeded by securing materials

or the positions of the pallet loads.

- If two-way entry pallets are being used, then the pallets must be so positioned that the correct air-flow

is not blocked by the supporting members.

-

The deck of the pallet may have to be slatted or perforated to allow free movement of controlled

temperature air. This is particularly important for cargoes (e.g. fruit) in packaging designed to allow

vertical through-movement of air.

Handling and Stowage

A flat unobstructed area, e.g. deck space, is best suited for positioning and stowing pallets. They should

never be dragged into nor out of the stowsuch treatment will collapse the pallet (particularly one-trip

pallets) and make subsequent handling and storage difficult if not impossible.

Vessels which have not been built with pallet handling in mind, e.g. without flush `tween deck hatch

coamings, etc., may need extensive preparation work carried out before loading commences, e.g.:

- Temporary wooden ramps to surmount hatch coamings.

- The removal of deck obstructions, e.g. ring-bolts, stanchions, etc.

- The bridging and squaring off of rounded bilges, excessive shear, etc.

- Temporary strengthening of hatch covers, tank tops, `tween decks, etc., with metal plates to allow

for axle loading of fork lift trucks.

- Point loadings may be very high when a fork lift truck is under load, and considerations should

- be given to the Classification Societies' point loading figures (usually expressed in tonnes per square

metre).

The stowage of the ship has to be planned with the strength and size of the units carefully considered.

Two-way entry pallets and skidded units should be stowed so that the truck always has an entry to the

cargo available. This is particularly important where the vessel is discharging at more than one port, and

is often referred to as the "flowline" of the pallets. This "flowline" should be marked on the cargo plan

with arrows.

If a solid stow is obtained immediately beneath the hatch square it is necessary to have key pallets clearly

marked on the stowage plan to indicate which have to be lifted out first to allow access to the remainder of

the stow and introduce the appropriate mechanical handling equipment. These pallets may with advantage,

under most circumstances, be left with slings in place at time of loading to aid the process of discharging.

Any dunnage used with palletised (or other unit) loads should be limited, and lengths kept short to prevent

obstructing or fouling mechanical equipment, cargo in the stow, and handling operations. Sometimes it is

necessary to place sheets of plywood, chipboard or fibreboard on edge in the stow to prevent the cargo

on one pallet "locking" with the next and so obstructing the unloading operation. It is important when

operating below decks with mechanical handling equipment that the decks are free of obstructions: loose

dunnage, rubbish, etc.

Making up Dockside Pallets

Where pallet loads are made up on the dockside for unit loading aboard ship, care must be taken that

bills of lading are not mixed on the pallet. Labelling of the pallet load should be carried out on at least

two sides.

The mixed loading (or discharging) of breakbulk cargo and unitised cargo will completely negate the

purpose of mechanised working, i.e. the fast handling of cargo with mechanical equipment and reduced

numbers in each gang. It is also more likely to result in cargo becoming jammed and damaged.

Cargo into Units

When cargo is not suitable, because of size, shape or other reason, to be palletised, it may sometimes

be made up into a unit load suitable for handling with mechanical equipment. This could be achieved in a

number of ways, e.g.:

Securing skids or bearers to the bottom of a suitably sized package or case. This would require at

least two such "skids" spaced to allow fork lift tynes entry. The minimum depth of the skids should be

50mm (2), but more suitable 65mm (2½). Making up the packages that form the unit in such a way that

space is left between the packages themselves for fork lift tynes to gain access. Typical commodities that

are suitable for this treatment are ingots, bricks, etc.

Pre-Slinging Techniques

Pre-slinging is normally used to facilitate the speed of cargo loading and/or discharging. Also to open up

the stow in way of the hatch square (see over).

It necessitates the positioning of sling loads of cargo in the stow at time of loading, leaving each unit with

the sling still encompassing the load so that the port of discharge has only to hook on and lift out.

With open hatch ships and twin hatches, the advantages to be gained by using pre-slinging techniques can

be great. Traditional hatch arrangements with deep wings are not so suitable since the sling load cannot be

landed directly from the hook to its stowed position.

A certain amount of space is lost (perhaps 10 or even 15%), but this is usually more than made up for in

the speed of cargo handling obtained. The space lost is less than that for palletised or skidded cargo, and the

cost of slings is probably competitive with the cost of pallets.

Materials

Any normal sling material may be used for a pre-slinging operation:

- Chain slings.

- Fibre rope.

- Steel wire rope.

- Flat synthetic fibre.

Also, under certain circumstances, nets, baskets or trays.

It is common for the following types of commodities to have the following types of sling:

Bagged Goods

Clover leaf slings, of natural or man-made fibre ropes and strops.

Reels of Paper and Newsprint

Flat synthetic strops, or endless slings often used in pairs.

Sawn Timber

Wire or flat synthetic choker strops. N.B. Bearers and dunnage must be used between units when using flat synthetic slings to avoid severe chafing damage in bad weather.

Cartons and Cased Goods, Bales and Pulp

Flat synthetic slingsalso rope or wire slings.

Steel Products

Various, depending on weight, unit shape, and number of potential lifting points. Round steel piping is

often pre-slung using two flat choker strops in a bridle. Steel plate, on the other hand, will usually require

wire or chain slings.

Handling

When loading it must be ensured that the sling eyes are left in an accessible position on top of the load

ready for immediate hooking on at time of discharging.

When discharging care must be taken that eyes from two adjacent units are not hooked on together in the

belief that they are from the same unit.

It is important that during handling operations a pre-slung load remains intact and does not become

broken up due to careless handling. If pre-slung loads do break up then there is immediately a labour

intensive operation required to move that cargo, and much of the advantage gained from pre-slinging is lost

due to higher costs in labour and time.

It is important that a series of pre-slung units be made up of the same number of bags, cartons or whatever,

so that tallying is made easier. Bills of lading should not be mixed in one pre-slung load.

The drift of the sling, when handling fragile items such as cartoned goods and small crates, etc., should

be sufficient to prevent pinching and crushing of the sling loads.

Slings should be of adequate strength and colour codes checked so that safe working loads and limitations

may be observed.

Small bags, e.g. of salt, may be made up into loads contained within large specially constructed bags.

This pre-slinging technique is practised widely in the West African trade. It should not be confused with

mini-bulk (but see also that section).

Summarized below some more details on general cargo ship cargo handling procedure and operational info:

-

Cargo handling procedure for general cargo ship

Suitable safety nets or temporary fencing should be rigged where personnel have to walk or climb across built-up cargo, and are therefore at

risk of falling .

More .....

-

Various cargo handling techniques

(a) Technological advances in ship design and lifting equipment

(b) Rapid development and increase in the tonnages of bulk cargo

(c) The impact of unitisation, and

(d) The new and modern techniques of refrigeration, particularly with container

carriage.

More .....

-

Cargo information rules

The MS (Carriage of Cargoes) Regulations 1999 (SI 1999/336) [Regulation 4(1)] specifies that the shipper must provide such information to the operator or master sufficiently

in advance of loading to enable them to ensure that:

• the different commodities to be carried are compatible with each other or suitably separated;.

More .....

-

Cargo packaging - general cargo ships procedure

To achieve compatibility between cargo

owners and the owners of the means of

transport requires knowledge of the

cargo-handling procedures in transport.

These procedures are described with

reference to major characteristics of

commodities and cargoes. .

More .....

-

Cargo stowage plan

The copies are forwarded to agents at ports of

discharge to allow the booking and reservation of labour, as appropriate. Relevant details of cargoes, i.e. total quantity, description of package, bales, pallets etc., tonnage, port of discharge,

identification marks and special features if and when separated .

More .....

-

Shipment procedure for cargoes in different forms

General cargo is a term that covers a great variety of goods. In regard to modern

cargo handling it refers to loose cargo that has not been consolidated for handling

with mechanical means such as unitised or containerised cargo. It refers to individual

items of any type of cargo, bagged or baled items, cases or crates, individual drums or

barrels pieces of machinery or small items of steel construction. .

More .....

-

Information exchange on cargo stowage and planning

Advance planning, exchange of information, and continuous ship to shore communication are all critical. All cargoes should be stowed and secured in a manner that will avoid exposing the ship and persons on board to unnecessary risk.

More .....

-

Lifting and carriage of deck cargo

The safe securing of all deck cargoes should be checked by a

competent person before the vessel proceeds on passage. The master is

responsible for ensuring that it is correctly stowed and adequately secured

for the intended voyage. Areas on the deck which are not to be used for

cargo stowage should be clearly marked or otherwise indicated. .

More .....

Cargo handling procedure for heavy indivisible loads

Heavy indivisible loads may be defined as those which, because of their mass and/or shape cannot be

handled by the normal gear available on board ship or on the quay alongside.

More .....

- Livestock handling brief procedure

The transport of animals is subject to legislation in many countries. Where risk of disease may exist this

legislation is rigorously enforced. In most cases the legislation not only covers the importation of animals,

but also the transit of animals, through a port.

More .....

- Unitised cargo handling technics for general cargo ship

A grouping together of two or more items (usually of a homogeneous nature) and securing them with

banding, glue, shrinkwrap, slings (e.g. clover leaf), to form a unit which, .

More .....

- Bagged Cargo handling procedure for general cargo ship

Bagged commodities need to be sufficiently robust to withstand external pressure and compression, as

the bag is designed to contain the contents rather than provide any substantial protection against external

damage. .

More .....

- Bales & bundles handling procedure for general cargo ship

Most baled commodities are impervious to damage from

rolling or dropping from limited heights. However, it can be dangerous to drop bales of rubber due to their

ability to bounce in any direction..

More .....

- Cases,Crates,Cartons, Drums,Barrels,Casks, etc.Handling technics

Cases and crates are usually constructed of plywood or thin low grade timber. Heavier cases may be built

up of 150mm×5mm (6×1) planks with strengthening pieces internally and externally while some are

built in a skeletal fashion to allow air to permeate through the contents and/or to reduce the weight. .

More .....

- DG Cargo handling procedure for general cargo ship

The IMDG Code recognises nine broad classes of Dangerous Goods. For the correct classification and

labelling of Dangerous Goods reference should be made to the IMDG Code. .

More .....

- Methods of ventilation used in general cargo ships

Ventilation of cargo may be necessary to remove heat, dissipate gas, help prevent condensation and/or

remove taint. Heat may be generated by live fruit, wet hides, vermin, and commodities liable to spontaneous

combustion .

More .....

- Methods of stowage used in general cargo ships

The stowage factor of any cargo is the volume which a certain amount in weight of

that cargo occupies. It is usually measures in cubic feet per long ton or alternatively in

cubic metres per metric ton. If the stowage factor is 20, it indicates a heavy cargo. If it

is 100, it indicates that the cargo is light.

More .....

- Special cargo handling in general cargo ships

Ventilation of cargo may be necessary to remove heat, dissipate gas, help prevent condensation and/or

remove taint. Heat may be generated by live fruit, wet hides, vermin, and commodities liable to spontaneous

combustion .

More .....

- Intermediate Bulk Containers ( I.B.C.)handling technics - general cargo ship procedure

An I.B.C. is a disposable or re-usable container designed for the carriage of bulk commodities in

parcels of between 0.5 and 3.0 tonnes.

More .....

- Dunnage requirement for general cargo ships

The traditional reasons for the use of dunnage have been largely superseded with the introduction of

containers and general cargo ships with shallower decks and holds.

More .....

- Methods of refrigeration used in general cargo ships

Refrigeration is essentially the removal of heat through

the process of evaporation. We choose to refrigerate

commodities such as fruits and vegetables because we

want to prolong their “practical shelf life” – the time from

harvest until the product loses its commercial value.

More .....

- Deck Cargo handling procedure for general cargo ship

A large variety of goods, because of their inherent properties (length, height, weight, etc.) may be carried

on deck. "On deck" means an uncovered space and includes deck houses having doors which can be

continuously open (except in heavy weather)..

More .....

-

Safe use of pesticides on board cargo ships

Ship's personnel should not handle fumigants and such operations

should be carried out only by qualified operators. Fumigation should only be

carried out with the agreement of the ship's master..

More .....

-

Types of packaging & stowage methods for break bulk cargo

The rigging time being negligible, and the crane is able to pick up and land permitted loads anywhere within its working radius. .

More .....

-

Various commodities carried by general cargo ships

Cargoes should be stowed and secured in a manner that will

avoid exposing the ship and persons on board to unnecessary risk. The safe

stowage and securing of cargo depends upon proper planning, execution

and supervision by properly qualified and experienced personnel. .

More .....

-

Methods of ventilation

The holds of most dry cargo ships are ventilated by a mechanical supply and natural exhaust system

.

More .....

-

Carriage of containers on cargo ships

The process of loading and securing

of goods into a container should follow the IMO/ILO/UN/ECE Guidelines

for Packing of Cargo Transport Units (CTUs). Special care should be taken

when lifting a container the centre of gravity of which is mobile, e.g. a tank

container, bulk container or a container with contents which are hanging..

More .....

-

Working in cargo spaces safely

Safety arrangements prior to working cargo should ensure that

adequate and suitable lifting plant is available, in accordance with the register

of lifting appliances and cargo gear, .

More .....

-

Cargo handling procedure for general cargo ship

Suitable safety nets or temporary fencing should be rigged where personnel have to walk or climb across built-up cargo, and are therefore at

risk of falling .

More .....

Machinery system main info pages

Home page||Cooling ||Machinery||Services ||Valves ||Pumps ||Auxiliary Power ||Propeller shaft ||Steering gears ||Ship stabilizers||Refrigeration||Air conditioning ||Deck machinery||Fire protection||Ship employment

||

Home ||

General Cargo Ship.com provide information on cargo ships various machinery systems -handling procedures, on board safety measures and some basic knowledge of cargo ships that might be useful for people working on board and those who working in the terminal. For any remarks please

Contact us

Copyright © 2010-2016 General Cargo Ship.com All rights reserved.

Terms and conditions of use

Read our privacy policy|| Home page||